GJM 25 Insulating Fire Brick - Mullite Insulation Brick Product

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Thermal Insulation Fire Clay Brick

Refractory brick is a refractory material used in lining furnaces, kilns, fireboxes, and fireplaces.

We provide high quality Refractory Fire Bricks that are used on wide range in the various industries like Cement, Glass and Steel. Refractory Fire Bricks are provided as per the quantity and specifications required by the customers. We provide an extensive range of Refractory Fire Bricks at reasonable prices that depend upon the quantity ordered.

Application

Insulating Fire Brick are used for the lining of converter, alternating current arc furnace, direct Current arc furnace and the ladle slag line, etc.

Company Advantage

(1)Long Insulating Fire Brick manufacture history: 25 years manufacturer

(2)Advanced equipment and good service

(3)Diversification of production standards: ISO ANSI FEPA JIS ASTM

(4)Flexible payment: T/T L/C D/P D/A

(5)Professional marketing team and after-sale service

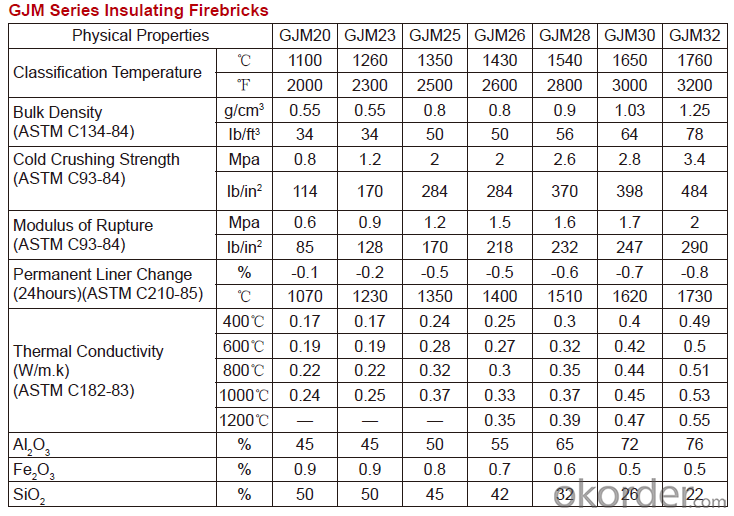

Insulating Fire Brick main feature:

Equipment

1 unit of Ceramic Abrasive (SG Abrasive) pilot production line

2 units of Compact grain Abrasive pilot production lines

1 unit of high-end coated abrasives (abrasive cloth) production line

3 large flexible crushing and sieving lines for grit production lines

6 units of 5000KVA-10000KVA dumping type electric arc furnaces for Brown Fused Alumina fusion

FAQs

Q1 What’s the transport method?

A1 FCL delivery goods with wooden pallet or wooden case by sea; If LCL delivery, must with wooden case; Sometimes need open top, flat rack or bulk cargo.

Q2 What’s the required payment term?

A2 Generally 30% TT as the prepayment, 70% TT before delivery. If need, 100% Irrevocable Letter of Credit or negotiation.

Q3 Which country are our products exported to?

A3 Apart from entire Chinese market, the US, Russia, Japan, Korea, Australia and some Southeast Asian Nations.

- Q: Are insulating fire bricks safe to use?

- When used correctly and according to the manufacturer's instructions, insulating fire bricks are generally safe to use. These bricks are specifically designed to endure high temperatures and provide exceptional insulation, making them perfect for applications like lining kilns, furnaces, and fireplaces. Made from lightweight materials like alumina, silica, and other refractory materials, insulating fire bricks aim to minimize heat transfer, thus preventing the escape of heat from the enclosed area. This not only enhances the system's energy efficiency but also reduces the risk of overheating and potential fires, improving safety. To ensure the safe use of insulating fire bricks, it is crucial to install them properly and securely. This involves providing sufficient support and reinforcement to prevent collapse or shifting of the bricks. Additionally, it is essential to use suitable mortar or refractory cement to firmly join the bricks together, creating a sturdy and stable structure. While insulating fire bricks themselves are generally safe, it is important to note that they may contain small amounts of trace elements or materials that can be harmful if released into the environment. Therefore, it is advisable to follow the manufacturer's safety guidelines, which may include wearing protective gloves, goggles, and a dust mask when handling the bricks. In conclusion, insulating fire bricks are a safe and dependable choice for insulation in high-temperature applications. Nevertheless, it is crucial to take necessary precautions during installation and adhere to safety guidelines to ensure their proper and safe use.

- Q: Can insulating fire bricks be used in the construction of smelting ovens?

- Yes, insulating fire bricks can be used in the construction of smelting ovens. Insulating fire bricks are designed to have low thermal conductivity, which means they are excellent at retaining heat. This property makes them ideal for applications where high temperatures need to be maintained, such as smelting ovens. Smelting ovens are used to melt and refine various metals and minerals. These processes involve extremely high temperatures, and it is crucial to minimize heat loss to ensure efficient and effective smelting. Insulating fire bricks can help achieve this goal by providing excellent insulation and reducing heat loss. Insulating fire bricks are made from lightweight materials, such as ceramic fibers or expanded clay, which have high insulating properties. They are capable of withstanding temperatures up to 3000°F (1650°C), making them suitable for the extreme heat generated in smelting ovens. Additionally, insulating fire bricks are resistant to thermal shock, meaning they can withstand rapid temperature changes without cracking or breaking. This is essential in smelting processes, which often involve heating and cooling cycles. Furthermore, insulating fire bricks are easy to work with and can be cut or shaped to fit specific dimensions or designs. This flexibility makes them highly adaptable for constructing smelting ovens of various shapes and sizes. In summary, insulating fire bricks are an excellent choice for the construction of smelting ovens due to their low thermal conductivity, high temperature resistance, thermal shock resistance, and ease of customization. They can help maintain high temperatures, reduce heat loss, and ensure efficient smelting processes.

- Q: Can insulating fire bricks be used in ceramic industry kilns?

- Yes, insulating fire bricks can be used in ceramic industry kilns. Insulating fire bricks are specifically designed to withstand high temperatures and are capable of providing insulation in kilns. They have low thermal conductivity, which helps to maintain consistent heat distribution within the kiln, resulting in more efficient firing processes. Additionally, insulating fire bricks are lightweight, making them easier to handle and install in kilns. Their ability to retain heat and resist thermal shock makes them an ideal choice for use in ceramic industry kilns.

- Q: Can insulating fire bricks be used in the construction of metal smelting molds?

- Yes, insulating fire bricks can be used in the construction of metal smelting molds. Insulating fire bricks are designed to withstand high temperatures and provide excellent thermal insulation, making them suitable for use in metal smelting molds where heat retention is crucial.

- Q: Can activated carbon be antiseptic?

- In addition to activated carbon carbon, also contains two kinds of admixtures: one is the combination of chemical elements, mainly hydrogen and oxygen, these elements are due to incomplete carbonization and the residue in the carbon, or in the process of activation, non carbon and activated carbon surface chemical foreign combination, such as the use of water vapor when activated, the surface of the active carbon is oxidized or water vapor oxidation; another kind of admixture is ash, it is part of the inorganic carbon in ash; activated carbon is easy to cause two pollution.

- Q: Do insulating fire bricks have a high thermal shock resistance?

- Yes, insulating fire bricks typically have a high thermal shock resistance. These bricks are specifically designed to withstand rapid changes in temperature without cracking or breaking. They are made from lightweight refractory materials that have low thermal conductivity, which helps to minimize heat transfer and prevent thermal stress. Additionally, insulating fire bricks often go through a firing process that further enhances their thermal shock resistance. Overall, these bricks are well-suited for applications where they are exposed to extreme temperature fluctuations, making them a reliable choice for insulation in high-temperature environments.

- Q: Can insulating fire bricks be used in DIY projects?

- Yes, insulating fire bricks can certainly be used in DIY projects. These bricks are lightweight and have excellent thermal insulation properties, making them suitable for various applications. They are commonly used in projects such as constructing wood-fired ovens, fire pits, kilns, and even for building the walls of a forge. Insulating fire bricks can withstand high temperatures and are resistant to thermal shock, making them a reliable choice for DIY enthusiasts who want to create heat-resistant structures. They are also easy to cut and shape, allowing for customization according to specific project needs.

- Q: Can insulating fire bricks be used for insulation in gas furnaces?

- Yes, insulating fire bricks can be used for insulation in gas furnaces. They are designed to withstand high temperatures and provide excellent insulation properties, making them suitable for use in gas furnaces to improve energy efficiency and enhance overall performance.

- Q: What is the typical moisture content of an insulating fire brick?

- The moisture content of an insulating fire brick can vary depending on factors such as its specific composition, the manufacturing process used, and the conditions in which it is stored. However, insulating fire bricks are typically designed to have minimal moisture content in order to enhance their insulation capabilities and resistance to thermal shock. Generally, insulating fire bricks have a moisture content ranging from 0.5% to 2%. This low moisture content is crucial in preventing the bricks from cracking or spalling when exposed to high temperatures. Additionally, it reduces the risk of damage caused by moisture, such as freeze-thaw cycles or the release of steam upon heating. To ensure the optimal performance and longevity of insulating fire bricks, it is advisable to store them in a dry environment and protect them from moisture during transportation and installation.

- Q: Are insulating fire bricks suitable for use in thermal power plants?

- Insulating fire bricks are indeed suitable for utilization in thermal power plants. By possessing low thermal conductivity, these bricks effectively retain heat and prevent its dissipation. In the context of thermal power plants, where elevated temperatures are generated, insulating fire bricks can be employed as linings for furnaces, boilers, and other apparatus to furnish thermal insulation and augment energy efficiency. Furthermore, these bricks exhibit resistance towards high temperatures and are capable of enduring thermal shocks, rendering them highly suitable for deployment in environments characterized by extreme heat. The utilization of insulating fire bricks in thermal power plants enables operators to curtail heat loss, enhance the overall efficiency of the plant, and bolster the durability and lifespan of the equipment.

Send your message to us

GJM 25 Insulating Fire Brick - Mullite Insulation Brick Product

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords