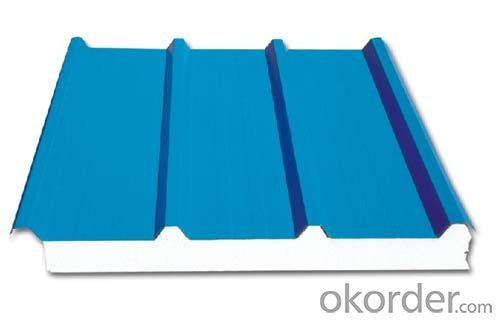

GI Prepainted corrugated steel sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Standard: | AISI,ASTM,BS,DIN,GB,JIS | Grade: | SGCC,SGHC,DX51D.. | Thickness: | 0.14-3.0mm |

| Place of Origin: | Shanghai China (Mainland) | Brand Name: | Model Number: | 600-1250mm | |

| Type: | Steel Plate | Technique: | Cold Rolled | Surface Treatment: | coated ,galvanized |

| Application: | building ,house,construction | Special Use: | Wear Resistant Steel | Width: | 600-1250mm |

| Length: | Any length | sample: | free available | quality: | first class |

| stock: | 5766tons | company type: | manufacturer & exporter | product name: | prepainted galvanized corrugated steel sheet |

Packaging & Delivery

| Packaging Detail: | 1.packed in bundles 2.waterproof packing 3.packed by steel strip 4.as per to clients |

| Delivery Detail: | within 5-20 days after receipt deposit or L/C at sight. |

Specifications

prepainted galvanized corrugated sheel sheet

1.Thickness:0.14-3.0mm

2.Width:600-1250mm

3.In stock

4.Fast delivery

prepainted galvanized corrugated steel sheet | |

Standard | AISI, ASTM, BS, DIN, GB, JIS |

Material | DX51D SGCC, DC51D,SPCC |

Thickness | 0.14-3.0mm |

Width | 600-1250mm(1250,1220,1000, 980mm, 900mm ,840mm, 820mm, 750mm) |

Coating | PE ,PVDF, HDP ,galvanized(30-300g), galvalume (AZ80) |

Color | According to RAL card |

Length | cut as client’s request, but considering the transportation , its better to cut less than 5.8 meter (for 20’ft container) , or 11.8 meter (for 40’ft container). |

Remarks | 1.Payment terms:T/T, L/C 2.Trade terms:FOB, CNF, CIF 3.Port:Shanghai 4.Supply ability:5000Tons/month 5.Delivery time: within 15-20 days after receiving the deposit. |

- Q: What is the bending radius for steel sheets?

- The bending radius of steel sheets is influenced by several factors, including the sheet's thickness, the type of steel utilized, and the particular application at hand. Typically, a widely accepted guideline suggests employing a bending radius that is no less than twice the thickness of the steel sheet. Nevertheless, this figure can fluctuate depending on the specific demands and constraints of the undertaking. It is crucial to seek guidance from engineering and fabrication specialists experienced in handling steel sheets to ascertain the suitable bending radius for a specific application.

- Q: What is the difference between a painted and laminated steel sheet?

- A painted steel sheet and a laminated steel sheet are both types of steel sheets that offer different characteristics and applications. A painted steel sheet is a steel sheet that has been coated with a layer of paint. This paint layer provides protection against corrosion and adds aesthetic appeal to the sheet. The paint can come in various colors and finishes, allowing for customization and versatility in design. Painted steel sheets are commonly used in architectural applications, such as roofing, siding, and wall cladding, as well as in automotive and appliance industries. The paint layer may require periodic maintenance to ensure its durability and appearance. On the other hand, a laminated steel sheet is created by bonding multiple layers of materials together. Typically, it consists of a steel core and one or more layers of other materials, such as plastic, polymer, or resin. The lamination process enhances the strength, durability, and performance of the steel sheet. Laminated steel sheets offer superior resistance against impact, scratching, and chemical exposure, making them suitable for applications that require high mechanical strength and protection, such as transportation, construction, and industrial equipment manufacturing. The laminate layers can also provide additional functionalities like sound insulation, thermal insulation, or fire resistance. In summary, the main difference between painted and laminated steel sheets lies in their composition and purpose. A painted steel sheet primarily focuses on aesthetics and corrosion protection, while a laminated steel sheet prioritizes strength, durability, and specialized functionalities. The choice between the two depends on the specific requirements of the application at hand.

- Q: Can steel sheets be used for artistic or sculptural projects?

- Yes, steel sheets can be used for artistic or sculptural projects. Steel sheets offer durability, strength, and versatility, making them a popular choice for artists and sculptors. They can be cut, shaped, welded, and manipulated to create various forms and designs, allowing artists to unleash their creativity and bring their visions to life. Additionally, steel sheets can be finished with different coatings or patinas to enhance their aesthetic appeal and protect them from corrosion.

- Q: What does steel plate "A3" mean?

- It can be used in all kinds of grinding tools, handles and other unimportant Abrasives parts

- Q: Can steel sheets be used for transportation applications?

- Yes, steel sheets can be used for transportation applications. Steel is a durable and strong material that can withstand the rigors of transportation, making it suitable for various applications such as automobile bodies, shipping containers, and railway carriages.

- Q: What are the properties of deep drawing properties in sheet steel?

- Refers to the change of the thickness of steel plate and the change of plane (length and width direction) when the steel plate is pressed.

- Q: Are steel sheets non-magnetic?

- No, steel sheets are not inherently non-magnetic. The magnetic properties of steel sheets depend on the specific composition and processing of the steel. Some types of steel, such as austenitic stainless steel, are non-magnetic, while others, such as ferritic and martensitic stainless steel, can be magnetic. The magnetic behavior of steel sheets can also be influenced by factors such as temperature and external magnetic fields. Therefore, it is important to consider the specific type and properties of the steel sheet in order to determine its magnetic behavior.

- Q: Are steel sheets suitable for magnetic shielding applications?

- Yes, steel sheets are suitable for magnetic shielding applications. Steel is a magnetic material, which means it can effectively redirect magnetic fields, thereby reducing their strength or preventing them from reaching certain areas. Steel sheets can be used as a barrier to shield sensitive electronic equipment and devices from external magnetic interference. The thickness and composition of the steel sheet can be adjusted to provide the desired level of magnetic shielding. Additionally, steel sheets are often cost-effective and readily available, making them a practical choice for magnetic shielding applications.

- Q: How do steel sheets compare to other materials in terms of durability?

- Compared to other materials, steel sheets are widely acknowledged for their exceptional durability. The long-lasting nature of steel can be attributed to its unique qualities, including high tensile strength and resistance to corrosion. Unlike wood or plastic, steel sheets are not easily susceptible to wear and tear, making them the preferred choice for various applications that require durability. Construction projects, automotive manufacturing, and industrial applications all benefit from the ability of steel sheets to withstand heavy loads without bending or warping. Furthermore, steel sheets have a longer lifespan than other materials, reducing the need for frequent replacements and maintenance. In summary, the durability of steel sheets is unparalleled, making them a dependable and cost-effective option for many industries.

- Q: Are steel sheets suitable for architectural roofing?

- Yes, steel sheets are suitable for architectural roofing. Steel is a highly durable and long-lasting material, making it an excellent choice for architectural roofing applications. Steel sheets offer significant strength, allowing them to withstand harsh weather conditions, including heavy rain, snow, and strong winds. They are also fire-resistant, which adds an extra layer of safety to the building. Moreover, steel sheets are lightweight compared to other roofing materials, making them easier to install and reducing the overall load on the structure. Additionally, steel sheets come in a variety of colors and finishes, allowing architects to achieve the desired aesthetic appearance for the building. Overall, steel sheets offer numerous advantages for architectural roofing, making them a suitable choice for both residential and commercial projects.

Send your message to us

GI Prepainted corrugated steel sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords