Geotextile Separation Membrane for Reinforcement and Drainage - CNBM

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 g/m²

- Supply Capability:

- 1000000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Filtration:

It can be the filtration layer of the dykes, river canal, seacoast, concrete slope, retaining walls. At the same time of preventing the clay granule from passing, it allows the water and the gas pass through freely.

Separation:

The isolation of the railway dregs and the roadbed, roadbed and the soft base, surface of the airdrome and parking lot and the groundsill, different dam materials. It isolates the soil and the gravel of two kinds different granule pathway from the groundsill or other buildings.

Reinforcement:

The highway, railway, soil-stone dam, breakwater, airport, backfill soil of retaining wall, slope protection, etc in which distributes the earth stress, prevents the side-displacement of the earth body and improves the earthbody stability.

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

After-sales service

1.In order to provide customers with comprehensive technical support,we will provide technical and other related information upon request in a timely manner.

2.In required,we will appoint specialized technicians to the construction site to give technical trainings to construction people,and offer technical guidance throughout the whole construction process.

3.For damage due to shipment and delivery,after we receive the complaint,we will check the issure through provided pictures and videos.If our responsibility is confirmed,we wil offer free replacement.

4.When the construction is completed,as your request,our technical staff may participate in the final acceptance.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

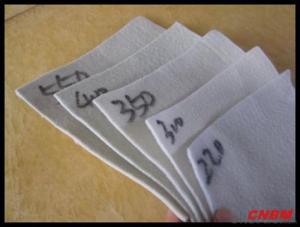

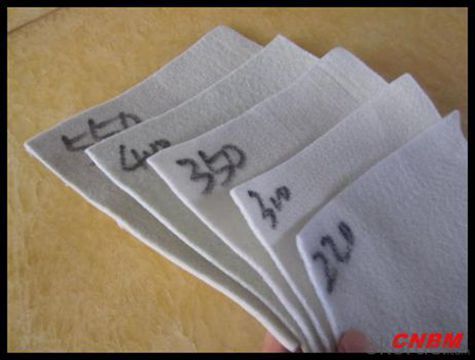

A: Yes, please check the pictures:

- Q: What are the specifications for geotextiles used in transportation projects?

- Geotextiles used in transportation projects typically have specific specifications in terms of their weight, thickness, tensile strength, permeability, and durability. These specifications ensure that the geotextiles can effectively separate, reinforce, or filter materials in the transportation infrastructure, such as roads, railways, or landfills. Additionally, they must meet certain industry standards and regulations to ensure their effectiveness and longevity in these projects.

- Q: Subgrade geotextile lap law need to suture it

- General geotextiles require stitching. Geotextile stitching must be carried out continuously. Before the overlap, the geotextile must overlap at least 150mm. The minimum seam distance from the geotextile edge is not less than 25mm.

- Q: Alteration of highway seepage control geotextile is generally placed in what position

- Apply to the grassroots level of water defense, the use of embedded, covered with thickness should not be less than 30CM, soil to be solid, to avoid uneven subsidence, cracks. Lap width should be greater than 15CM.

- Q: How do geotextiles contribute to the efficiency of drainage systems?

- Geotextiles contribute to the efficiency of drainage systems by providing two main benefits. First, they act as a filter to prevent soil particles from clogging the drainage pipes or systems, allowing for a consistent flow of water. Second, they help to distribute the water evenly across the entire drainage area, improving the overall effectiveness of the system.

- Q: How do geotextiles affect groundwater flow?

- Geotextiles can either enhance or restrict groundwater flow depending on their permeability and installation method. Permeable geotextiles can allow water to infiltrate through them, facilitating groundwater recharge and promoting natural drainage. Conversely, impermeable geotextiles can prevent water from passing through, altering the natural flow of groundwater and potentially causing waterlogging or surface runoff issues. The selection and proper installation of geotextiles are crucial to ensure they positively impact groundwater flow and maintain the hydrological balance of an area.

- Q: Cement concrete bridge is a film curing or geotextile maintenance

- Commodity concrete pouring is completed, should be in the slurry after grinding as soon as possible to cover and sprinkler conservation. Commodity concrete bridge deck with full coverage of sprinkler conservation methods, covering materials with two sticky one geotextile, every 1t sprinkler once, to ensure the quality of conservation, to prevent cracks.

- Q: What are the maintenance requirements for geotextile-reinforced retaining walls?

- The maintenance requirements for geotextile-reinforced retaining walls typically include regular inspections to check for any signs of damage, erosion, or settlement. Additionally, it is important to ensure that the drainage system is functioning properly to prevent water accumulation behind the wall. Any necessary repairs or adjustments should be promptly addressed to maintain the structural integrity of the retaining wall.

- Q: Geotextile laying should be beyond the edge of how to set the number of specific requirements? Which specification is more detailed

- Can be more than 1 meter or so, I am specializing in the production of geotechnical materials, wish smooth

- Q: What are the different guidelines for geotextile installation in erosion control projects?

- There are several guidelines for geotextile installation in erosion control projects. Firstly, it is important to properly prepare the soil surface by removing all vegetation, debris, and loose soil. The geotextile should then be placed directly on the prepared surface, ensuring that it is smooth and free of wrinkles or folds. It is crucial to overlap the geotextile seams by the manufacturer's recommended distance and secure them with staples or other appropriate fasteners. Additionally, the geotextile should be anchored using anchor trenches or pins to prevent movement. Finally, proper maintenance and inspection of the geotextile should be carried out regularly to ensure its effectiveness in erosion control.

- Q: What are the key considerations for geotextile installation in seismic retrofitting projects?

- Some key considerations for geotextile installation in seismic retrofitting projects include selecting the appropriate type and strength of geotextile material, ensuring proper placement and anchoring of the geotextile, evaluating the stability and drainage requirements of the site, and considering the compatibility of the geotextile with other materials and construction methods used in the retrofitting project. Additionally, careful attention should be given to the design and installation of the geotextile to ensure it effectively enhances the overall stability and performance of the structure during seismic events.

Send your message to us

Geotextile Separation Membrane for Reinforcement and Drainage - CNBM

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 g/m²

- Supply Capability:

- 1000000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords