Geotextile Gravel Driveway Road Building Constructive Felt Fabric Price Per M2

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 g/m²

- Supply Capability:

- 1000000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Made from polyester(PET)short fiber by nonwoven needle punched manufacturing process, it has isolation, filteation,drainage, reinforcement, protection and maintenance etc. function.

Specification:

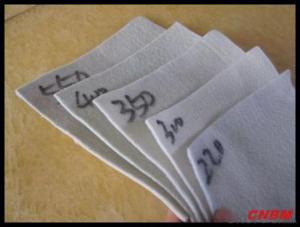

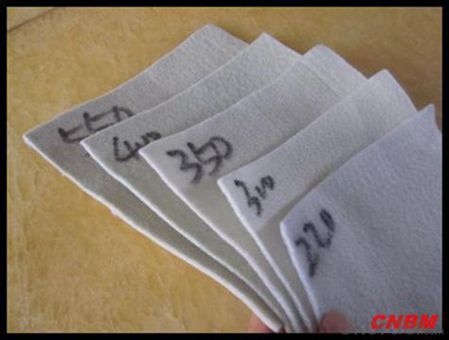

Mass Per Unit Area: 100-900g/m2

Fiber Type: Staple fiber

Color: White, Black, Grey etc.

Width Range: 1-6m

Length: as consumer request

Weight: 200g/m2--800g/m2Width: 1m-4m

Length: 30m-60m

Color: Any colors available or customers colors

Packing: Transparent polybag or White PP woven bag

Technics: Needle punchded/non woven

Productivity: More than 10000 sqms/day

Place of origin: Shandong, China

Load quantity Around 4000-12000m2 in 1x20ft

container,Around 17000-30000m2 in 1X40HQ container

Delivery time: Within 25-30 working days after receiving your advance money

Payment term: T/T, L/C,D/PPort: Qingdao, China

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

After-sales service

1.In order to provide customers with comprehensive technical support,we will provide technical and other related information upon request in a timely manner.

2.In required,we will appoint specialized technicians to the construction site to give technical trainings to construction people,and offer technical guidance throughout the whole construction process.

3.For damage due to shipment and delivery,after we receive the complaint,we will check the issure through provided pictures and videos.If our responsibility is confirmed,we wil offer free replacement.

4.When the construction is completed,as your request,our technical staff may participate in the final acceptance.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: Can geotextiles be used in pond liner systems?

- Yes, geotextiles can be used in pond liner systems. Geotextiles are often used as an additional layer in pond liner systems to provide protection, filtration, and stability. They can help prevent punctures, control soil erosion, and improve water quality by filtering out fine particles.

- Q: What is the separation between the roof waterproof protective layer and the waterproof layer?

- That is, at home and home boundaries to break off. Or can not achieve the effect of waterproof

- Q: Can geotextiles withstand harsh weather conditions?

- Yes, geotextiles are designed to withstand harsh weather conditions. They are made from durable materials that can resist extreme temperatures, heavy precipitation, and UV radiation. Additionally, geotextiles have excellent drainage properties, ensuring they can handle excessive moisture and prevent erosion even in challenging weather conditions.

- Q: 300 grams of geotextile how much money a square meter

- Geotextile, also known as geotextile, it is made of synthetic fiber through acupuncture or woven from the permeability of geosynthetics. Geotextile is a new material geosynthetics which one, the finished product for the cloth, the general width of 4-6 meters, the length of 50-100 meters. Geotextile is divided into a spinning geotextile and non-woven filament geotextile. Ordinary about 2.00 friends

- Q: How are geotextiles tested for permeability?

- Geotextiles are tested for permeability using various standardized methods such as the constant head method, falling head method, and the flexible wall permeameter. These tests involve measuring the flow of water through the geotextile under controlled conditions to determine its permeability characteristics.

- Q: How do geotextiles help with soil erosion control?

- Geotextiles help with soil erosion control by acting as a barrier between the soil and water, preventing the loss of soil particles. They also improve soil stability by increasing its strength and reducing the impact of erosive forces such as wind or water flow.

- Q: Composite geotextile 20-500-0.5 what it means

- You should not write it right

- Q: Where to sell waterproof geotextile

- Building materials market should have hope to help you

- Q: How do geotextiles help with erosion control on coastal cliffs?

- Geotextiles help with erosion control on coastal cliffs by acting as a barrier that prevents the soil from being washed away by the force of waves and rainwater runoff. These synthetic fabrics are placed along the cliff face to stabilize the soil and hold it in place, reducing the impact of erosion. Additionally, geotextiles promote vegetation growth by providing a suitable environment for plants to establish roots, further reinforcing the soil and preventing erosion.

- Q: Google for a long time only geotextile ads! The The Do not know geotextile, drainage board such materials, in what kind of shop which has to sell? Because the building materials market to a circle, people did not sell this thing more

- I professional production of drainage board, geotextile, geomembrane and other products, wish smooth

Send your message to us

Geotextile Gravel Driveway Road Building Constructive Felt Fabric Price Per M2

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 g/m²

- Supply Capability:

- 1000000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords