Geotextile Polyester 3D Composite Drainage Network

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 500000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

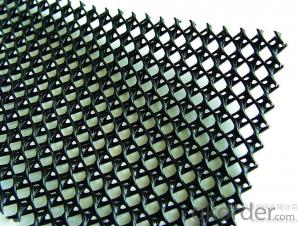

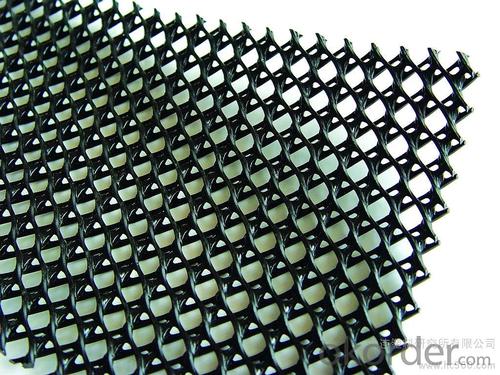

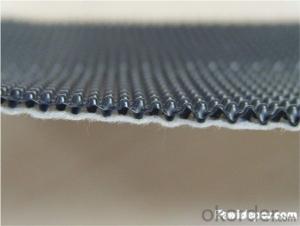

Description Of Three-dimensional Composite Drainage Network

Three-dimensional composite drainage network is a new type of drainage geosynthetic materials.

With high density polyethylene (HDPE) as raw material, after special extrusion process forming special structure

with three layers. The middle rod with a good rigidity, end-to-end setup, formating drainage channels;

The top and bottom cross rod form support to prevent geotextile embedded drainage channel,

even under high load can keep high drainage performance.

Main Features of Three-dimensional Composite Drainage Network

1. Drainage is strong. ((the equivalent of about one meter thick gravel drainage)

2. High tensile strength.

3. To reduce the probability of geotextiles embedded into core, maintain long-term stability of the drainage.

4. Long-term load is under great pressure. ( Can carry about 3000 ka compression load)

5. Corrosion resistance, acid and alkali resistance, long service life.

6. Construction is convenient,shorten the construction period,reduce the cost.

Specifications of Three-dimensional Composite Drainage Network

Properties | Unit | |

Unit Weight | g/m2 | 700g-1600g |

Thickness | mm | 5-8 |

Elongation | % | 50 |

Tensile strength (core network) | kN/m | 8-14 |

Hydraulic conductivity | m/s | K*10-4 ~ k*10-3 |

Geotextile | g/m2 | 200-200; 300-300; as your request |

Width | m | 2 |

Length | m | 30 or as your request |

Three-dimensional Composite Drainage Network Images

FAQ

1. Do you supply free samples for customers?

Yes,we will supply free samples for you.Please send your address for us.

2. How Many years experience do you have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q: Do you have a drainage board and a geotextile on the basement roof?

- Hello, generally do not require re-test Huazhi geotextile materials, manufacturers need to answer for your needs

- Q: How do geotextiles contribute to disaster management?

- Geotextiles contribute to disaster management by providing effective erosion control, stabilizing slopes, and preventing soil movement during natural disasters such as floods, landslides, and earthquakes. They also help in the construction of temporary shelters, emergency access roads, and retaining walls, enabling quick response and recovery efforts after a disaster. Additionally, geotextiles can be used for water filtration, drainage, and reinforcement, enhancing the overall resilience and effectiveness of disaster management strategies.

- Q: Can geotextiles be used for erosion control in mining sites?

- Yes, geotextiles can be used for erosion control in mining sites. Geotextiles are commonly employed in mining operations to stabilize the soil, prevent soil erosion, and control sedimentation. They can effectively reduce the impact of erosion caused by wind, water, and other environmental factors, thereby helping to maintain the integrity of mining sites and minimize environmental damage.

- Q: Water stability grassroots health permeable geotextile or plastic film is good?

- To achieve the desired health, filter the effect of water, must be geotextile, only to cope, it can only be plastic film friends

- Q: Do you have a drainage board and a geotextile?

- How many dishes? Drainage board and geotextile a square need about 15 yuan cost, their trade-off

- Q: How do geotextiles help with reinforcement of geogrids?

- Geotextiles help with the reinforcement of geogrids by providing a stable base and preventing soil erosion. They act as a separation layer between the geogrid and the soil, distributing the load evenly and increasing the overall strength and stability of the structure.

- Q: Can geotextiles be used in shoreline erosion control projects?

- Yes, geotextiles can be effectively used in shoreline erosion control projects. Geotextiles are permeable fabrics that can be installed along shorelines to stabilize the soil and prevent erosion caused by waves and currents. They can be used as a layer to separate the soil from the water, allowing for water filtration while reducing soil erosion.

- Q: What are the key considerations for geotextile installation in seismic zones?

- The key considerations for geotextile installation in seismic zones include the selection of appropriate geotextile materials, careful placement and anchoring of the geotextile to withstand seismic activity, and ensuring proper design and engineering to account for the dynamic forces generated during earthquakes. Additionally, the geotextile installation should be done in accordance with local building codes and regulations specific to seismic zones to ensure the safety and effectiveness of the geotextile system.

- Q: The technical parameters of woven geotextile

- Test items / specifications 0400 Remarks breaking strength (longitudinal) KN / m ≥ 17. Breaking strength (horizontal) KN / m ≥ no special requirements by the meridional 0.7 / 1 longitudinal and transverse elongation at break% ≤ 25 vertical and horizontal trapezoidal torn Strength, KN ≥ 0.180.200.270.340.410.480.600.72 vertical and horizontal CBR top breaking strength, KN ≥ 1.41.62.43.24.04.86.07.5 equivalent aperture O95 (O95) mm0.07-0.5 vertical permeability coefficient cm / sK × (10-1-10-4) K = 1.0-9.9

- Q: Why do you want to add 1 to the amount of geotextile

- There are overlapping area and loss, I am specializing in the production of geotextiles

Send your message to us

Geotextile Polyester 3D Composite Drainage Network

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 500000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords