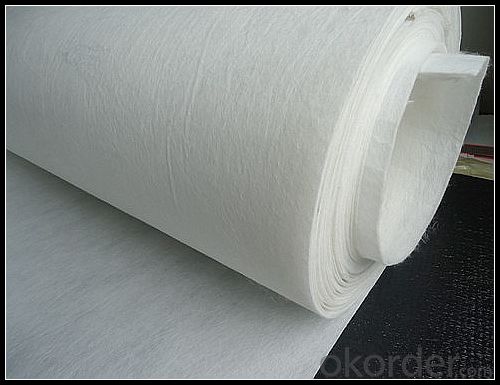

Geotextile Leroy 100% Polyester Filament Non-Woven Geotextile Road Building Constructive Felt Fabric

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1) Weight / Mass: 100g/m2-800g/m2

2) Width: Within 8 m (1m-8m)

3) Length: 50m-100m/roll (as request)

Application:

Water Conservancy

Material:

PP(polypropylene) PET (polyester)

Certificate:

CE/ISO9001

Break Elongation:

25%~100%

Tensile Strength:

from 2.5 KN/m to 25KN/m

Functions

1.Separation

The isolation of the railway dregs and the roadbed, roadbed and the soft base, surface of the airdrome and parking lot and the groundsill, different dam materials. It isolates the soil and the gravel of two kinds differentgranule pathway from the groundsill or other buildings.

2.Reinforcement

The highway, railway, soil-stone dam, breakwater, airport, backfill soil of retaining wall, slope protection, etc in which distributes the earth stress, prevents the side-displacement of the earth body and improves the earthbody stability.

3.ProtectionIt prevents the bank from being washed out, protects the bank and the bottom, prevents the water and soil from being washed away

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: Can geotextiles be used for separation of different soil layers?

- Yes, geotextiles can be used for the separation of different soil layers. Geotextiles are permeable fabrics that can be placed between different soil layers to prevent mixing and maintain their distinct properties. They act as a barrier, allowing water to pass through while preventing the migration of fine particles. This separation helps in enhancing the stability and performance of the soil layers, reducing the risk of settlement and maintaining the integrity of the construction project.

- Q: What kind of geotextiles are used in highway geotextiles?

- Highway geotextile is a new type of civil artifacts material, for the construction of geotextile highway can also be Hongxiang filament geotextile, not only need to resist the complex stress under the comprehensive mechanical properties of tensile properties, etc. But also to ensure that a variety of natural factors under the influence of a long time, the overall performance does not produce significant attenuation, that is, long-term stability, high and low temperature performance, anti-aging properties. Hongxiang filament geotextile can improve the carrying capacity of the road, can improve the road in the process of using the structure of the destruction of the problem

- Q: Can geotextiles be used in agricultural waste management systems?

- Yes, geotextiles can be used in agricultural waste management systems. They are often used for soil stabilization, erosion control, and filtration in agricultural applications, including waste management systems. Geotextiles can help to prevent soil erosion, filter out pollutants, and promote water drainage in these systems, making them an effective solution for managing agricultural waste.

- Q: What are the challenges associated with geotextile installation?

- Some challenges associated with geotextile installation include: 1. Site preparation: Properly preparing the site before installing geotextiles can be challenging. It requires clearing the area of any debris, grading the surface, and ensuring a stable foundation. 2. Handling and transportation: Geotextiles can be bulky and heavy, making their handling and transportation challenging. Special equipment or manpower may be required to move and position them correctly. 3. Installation accuracy: Achieving precise alignment and placement of geotextiles is crucial for their effectiveness. It can be challenging to ensure proper positioning, especially in complex or irregular terrain. 4. Seaming and joining: Geotextiles often need to be seamed or joined together to cover larger areas. Achieving strong and reliable seams can be challenging, as it requires proper techniques and materials to ensure the integrity of the installation. 5. Durability and longevity: Geotextiles need to withstand environmental factors such as UV exposure, temperature variations, and chemical exposure. Ensuring their durability and longevity can be a challenge, as these factors can degrade the material over time. 6. Quality control: Proper quality control measures are necessary to ensure the geotextile installation meets the required standards. This includes performing regular inspections, testing, and adherence to specifications, which can be challenging to implement and maintain consistently. Overall, geotextile installation requires careful planning, skilled labor, and adherence to industry standards to overcome these challenges and achieve a successful installation.

- Q: Can geotextiles be used for reinforcement of landfills?

- Yes, geotextiles can be used for the reinforcement of landfills. Geotextiles are permeable fabrics that are used to improve the stability, drainage, and filtration of soil in various applications, including landfill construction. They are often employed to prevent soil erosion and provide support to the landfill structure, enhancing its overall stability and longevity.

- Q: Today someone told me about a boyfriend, said to be geotextile. I wonder, geotextile cloth is what cloth? Is there there? Why is it used More

- Geotextile geotextile, also known as geotextile, it is made of synthetic fibers through the needle or woven from the permeability of geosynthetics. Finished cloth for the cloth, the general width of 4-6 meters, the length of 50-100 meters. Geotextile is divided into a woven geotextile and non-woven geotextile. Geotextile has excellent filtration, isolation, reinforcement protection, high tensile strength, good permeability, high temperature, anti-freeze, anti-aging, corrosion resistance. Divided into: non-woven geotextile, a textile geotextile (reinforced geotextile), warp knitted geotextile with demand can contact: Fang Lingyan Tel:

- Q: Can geotextiles be used in underground construction projects?

- Yes, geotextiles can be used in underground construction projects. They are commonly used to separate different soil layers, provide filtration, drainage, and erosion control. Geotextiles can also enhance the stability and strength of the underground structures by providing reinforcement and preventing soil movement.

- Q: How do geotextiles help with subgrade stabilization in road construction?

- Geotextiles help with subgrade stabilization in road construction by acting as a barrier between the unstable or weak subgrade soil and the overlying layers of the road. They prevent the mixing of different soil layers, providing separation and reinforcement. Geotextiles distribute the load more evenly, reducing stress on the subgrade and minimizing deformations and settlements. Additionally, they improve drainage by allowing water to pass through while preventing soil erosion, ensuring long-term stability and durability of the road.

- Q: Can the geotextile function be a filter?

- Hello, geotextile is the most important role is to filter, some of the above works of water filter material is mainly used geotextile, geotextile price is relatively low, relatively high tensile strength, can play a filtering effect. Zhongrui geotech Zhang Mingchao answer for you.

- Q: What are the environmental impacts of using geotextiles?

- The use of geotextiles can have several positive environmental impacts. They help prevent soil erosion by stabilizing slopes and retaining sediment, which reduces the amount of pollutants entering water bodies. Geotextiles also promote vegetation growth by acting as a barrier against weeds and protecting newly planted seeds. Furthermore, they can be used in landfills to prevent leachate contamination and promote proper waste management. Overall, geotextiles contribute to sustainable land use and reduce the negative environmental effects associated with erosion and pollution.

Send your message to us

Geotextile Leroy 100% Polyester Filament Non-Woven Geotextile Road Building Constructive Felt Fabric

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords