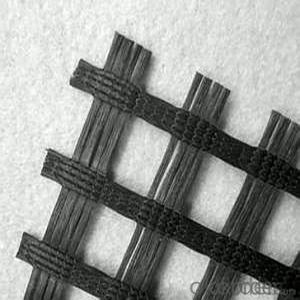

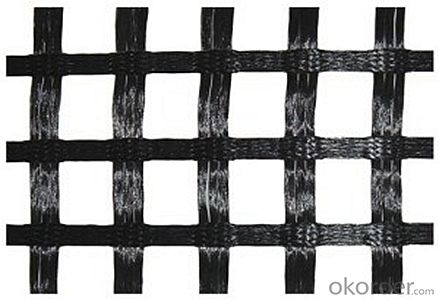

Geotextil No Tejido 1600 Reinforcement and Separation Fiberglass Geogrid

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

Main application objects of the materials:

Reinforcement of highways slopes and higher steepness slopes fixation;

Bed fixation of the various types of road surfacing;

Reinforcement of littoral zone of water reservoirs and greek beds;

Fixation of the railroad cone slopes;Support wall construction.

“Technostroytex” LLC geogrids are a honeycomb of polyethylene bands of 1.7 mm thickness (standard), bound by ultrasonic welding joints chequerwise.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

After-sales service

1.In order to provide customers with comprehensive technical support,we will provide technical and other related information upon request in a timely manner.

2.In required,we will appoint specialized technicians to the construction site to give technical trainings to construction people,and offer technical guidance throughout the whole construction process.

3.For damage due to shipment and delivery,after we receive the complaint,we will check the issure through provided pictures and videos.If our responsibility is confirmed,we wil offer free replacement.

4.When the construction is completed,as your request,our technical staff may participate in the final acceptance.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: What are the key factors affecting the hydraulic conductivity of geotextiles?

- The key factors affecting the hydraulic conductivity of geotextiles include the size and shape of the geotextile fibers, the porosity of the material, the thickness of the geotextile, and the applied pressure or load. Other factors that can influence the hydraulic conductivity include the type of soil or aggregate being filtered, the presence of any clogging materials, and the overall condition and integrity of the geotextile.

- Q: What are the factors to consider when designing geotextile tubes for dewatering?

- When designing geotextile tubes for dewatering, there are several factors to consider. These include the nature and composition of the sediment or sludge to be dewatered, the required dewatering rate, the size and shape of the geotextile tubes, the strength and permeability of the geotextile material, the location and environmental conditions, and the availability of equipment for filling and handling the tubes. Additionally, factors such as cost, durability, and the potential for reuse or disposal of the dewatered material should also be taken into account.

- Q: Are geotextiles suitable for high-traffic areas?

- Yes, geotextiles can be suitable for high-traffic areas. Geotextiles are durable and can provide reinforcement to the underlying soil, reducing erosion and enhancing stability. They can effectively distribute the load of heavy traffic and help maintain the integrity of the ground surface. However, the selection of the appropriate geotextile type and specification must be based on the specific requirements and conditions of the high-traffic area.

- Q: Can geotextiles be used in mining and tailings management applications?

- Yes, geotextiles can be used in mining and tailings management applications. Geotextiles are often utilized in mining operations to help control erosion, reinforce soil, and provide drainage. They can also be used in the management of tailings, which are the waste materials generated from mining activities, to prevent soil contamination and enhance stability.

- Q: Can geotextiles be used for drainage purposes?

- Yes, geotextiles can be used for drainage purposes. They are often used to enhance the drainage capacity of soil by allowing water to flow through while preventing soil erosion. Geotextiles can be employed in various applications such as road construction, landfills, and agricultural fields to improve drainage and prevent waterlogging.

- Q: Can geotextiles be used for reinforcement of earthen dams?

- Yes, geotextiles can be used for the reinforcement of earthen dams. Geotextiles are commonly employed in dam construction projects to enhance the stability, strength, and erosion resistance of earthen embankments. They act as a barrier, preventing the loss of soil particles while still allowing for water drainage, thereby improving the overall performance and longevity of the dam.

- Q: How do geotextiles contribute to green building certifications?

- Geotextiles contribute to green building certifications by promoting sustainable construction practices. These specialized fabrics are used to enhance soil stability, control erosion, and manage stormwater runoff, resulting in improved site conditions and reduced environmental impacts. By incorporating geotextiles, construction projects can meet various criteria for green building certifications, such as water efficiency, site development, and erosion control, ultimately contributing to more sustainable and environmentally-friendly structures.

- Q: Can geotextiles be used in geogrid reinforced slopes?

- Yes, geotextiles can be used in geogrid reinforced slopes. Geotextiles are often used in combination with geogrids to provide additional reinforcement and prevent soil erosion in reinforced slopes. They help to distribute the load and improve the stability of the slope by acting as a separation layer between the soil and the geogrid.

- Q: How do geotextiles help in reducing the risk of slope failures?

- Geotextiles help in reducing the risk of slope failures by providing reinforcement and stabilization to unstable slopes. These materials are placed within the slope to increase its strength and prevent erosion. Geotextiles also help in promoting water drainage and filtration, which reduces the build-up of hydrostatic pressure within the slope. Overall, geotextiles enhance the stability of slopes and mitigate the potential for landslides or slope failures.

- Q: Can geotextiles be used in the construction of stormwater ponds?

- Yes, geotextiles can be used in the construction of stormwater ponds. Geotextiles are often used as a lining material to reinforce the pond's base and slopes, providing stability and preventing erosion. Additionally, geotextiles can act as a filter, preventing fine particles from entering the pond and improving water quality.

Send your message to us

Geotextil No Tejido 1600 Reinforcement and Separation Fiberglass Geogrid

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords