Geotextil De Polipropileno Short Non-Woven Geotextile Fabric 300gsm for Railway-CNBM

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. High tension.Because it's made of Plastic flat yarn,it can keep enough tenacity and stretching.

2. Non-corrosive.It can be non-corrosive for long time in soil and water with different PH value.

3. Good Water Permeability.There is space between flat yarn,so it has good water permeability.

4. Good antimicrobic. For organisms,there will be no worm-holes.

5. Easy construction.Because of light material,soft,it's easy for transportation,spreading out and construction.

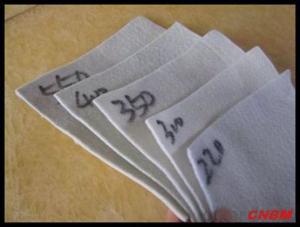

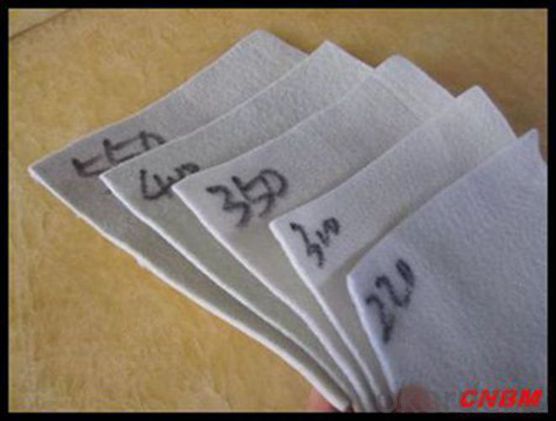

short fiber geotextile

Key Specifications/Special Features:

Specifications

1) PET geotextile: non woven geotextile

2) Material: PP (polypropylene) or Polyester fibers

3) 100g/sq.m-1000g/sq.m

4) Width: 2m-6.5m

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

Our Service

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: What is the seepage geotextile

- Is the kind of ordinary geotextile

- Q: Are geotextiles suitable for use in drainage ditches?

- Yes, geotextiles are suitable for use in drainage ditches. Geotextiles are often used to enhance the performance of drainage systems by providing filtration, separation, and reinforcement. They can help prevent soil erosion, retain fine particles, and improve water flow, making them an effective solution for drainage ditch applications.

- Q: Geotextile cost how much money a flat

- Geotextile laying - including the labor costs (according to geotextile specifications and laying conditions and requirements are different), material costs (specific quality requirements and thickness, are not the same ..), mechanical use costs (such as transport, sewing System, hoisting, etc.). The price is different. Sometimes the construction of our geotextile laying, the price per square meter from 9 yuan to 50 yuan range.

- Q: What are the different geotextile installation equipment and tools?

- Some of the different geotextile installation equipment and tools include geotextile dispensers, spreaders, rollers, staplers, and anchors. These tools are used to ensure proper placement and securement of geotextiles in various construction and environmental applications.

- Q: How do geotextiles affect soil consolidation?

- Geotextiles have a positive impact on soil consolidation as they provide reinforcement and stabilization. By acting as a barrier, they prevent the mixing of different soil layers, reducing the potential for settlement and increasing the overall strength of the soil. This consolidation is achieved through the interlocking of geotextile fibers with the soil particles, enhancing the load-bearing capacity and preventing the loss of fine particles.

- Q: What are the challenges associated with geotextile installation?

- One of the main challenges associated with geotextile installation is ensuring proper alignment and placement of the material. Geotextiles need to be installed in a specific manner to effectively perform their intended functions, such as erosion control or soil stabilization. Achieving the right alignment can be difficult, especially in areas with uneven terrain or limited access. Another challenge is securing the geotextile in place. Since these materials are often lightweight and flexible, they can easily shift or become displaced during installation. Proper anchoring techniques, such as using staples or pins, are necessary to prevent movement and maintain the integrity of the installation. In addition, the type and condition of the underlying soil can pose challenges. Geotextiles require a stable and well-compacted base for optimal performance. If the soil is soft or unstable, additional measures such as soil stabilization techniques or geogrids may be necessary to ensure proper installation. Lastly, weather conditions can also impact geotextile installation. Wind, rain, or extreme temperatures can make the process more difficult and may require additional precautions or delays. Proper planning and coordination with weather forecasts are essential to mitigate these challenges and ensure a successful geotextile installation.

- Q: Can geotextiles be used in the construction of landfills?

- Yes, geotextiles can be used in the construction of landfills. Geotextiles are often used as a barrier or liner material in landfills to help prevent the migration of contaminants and control the flow of leachate. They are commonly used to enhance the stability, durability, and environmental performance of landfill systems.

- Q: What are the different geotextile installation techniques for erosion control blankets?

- There are several geotextile installation techniques for erosion control blankets, including anchoring, stapling, trenching, and pinning. Anchoring involves using stakes or pins to secure the blanket to the ground. Stapling uses staples or nails to attach the blanket directly to the soil. Trenching involves burying the edges of the blanket in a shallow trench to prevent water from getting underneath. Pinning involves using metal pins or stakes to secure the blanket to the ground. Each technique has its advantages and is chosen based on the specific needs and conditions of the erosion control project.

- Q: Geotextile seepage seams how to deal with

- Hand wrap the sewing machine and seal it.

- Q: Geotextile geomembrane factory need to record, certificate, inspection report?

- Do not need to see if the time is not your company's chapter to know ah

Send your message to us

Geotextil De Polipropileno Short Non-Woven Geotextile Fabric 300gsm for Railway-CNBM

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords