Geotextile Filter Fabric Home Depot - Geomembrane Type HDPE LDPE Material

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Type:

Waterproof Membrane

Description

(middle) density polyethylene geomembrane is made from HDPE resin

And additives such as antioxidant, light-stabilize and carbon black, etc. It is extensively used for landfills, sewages, mining, environmental protections and irrigation projects.

Place of Origin:

Shandong, China (Mainland)

Brand Name:

CMAX

Model Number:

ISO

Sample:

Available

Color:

customized

width:

4m-9m

thickness:

1mm-3mm

length:

customized

material:

geotextile+HDPE membrane/geote

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

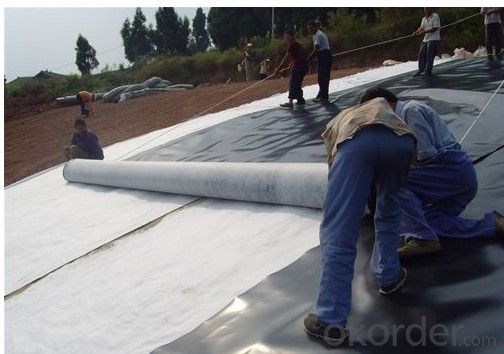

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: How do geotextiles contribute to disaster management?

- Geotextiles play a crucial role in disaster management by providing effective solutions for various disaster-related challenges. They can be used to reinforce unstable slopes, control erosion, and stabilize soil during floods, earthquakes, or landslides. Geotextiles also aid in the construction of temporary roads, shelters, and embankments, allowing for easier access to affected areas and facilitating relief operations. Their ability to filter and drain water helps in managing excess rainfall or groundwater, preventing further damage. Overall, geotextiles are versatile and reliable tools that contribute to mitigating and managing the impacts of disasters.

- Q: Sng400-2.5gb / t-1998 geotextile is what the specifications

- SNG400-2.5 refers to the national standard polyester staple acupuncture non-woven geotextile 400g / ㎡, width 2.5m. The standard code for the GB / T-1998 staple fiber nonwoven geotextile is generally the SNG / (1) (2) / (3) - (4) / (5). (1) that the use of raw materials fiber code: PET-polyester, PP-polypropylene, PA-nylon, PV-vinylon, PE-Ethylene (conventional polyester are generally vacant omitted code) (2) that polyester staple fiber non-woven Geotextile per unit area weight. (3) that the composite products in the polyester staple fiber non-woven geotextile weight per unit area, non-composite product vacancies. (4) width, expressed in meters (5) production department number: can express the product more specific characteristics, functions, varieties, sequences, etc., the general vacancy. For example, 2.5m wide 400g / ㎡ polyester staple fiber non-woven geotextile representation of the method can be SNG / PET400-2.5, can also be expressed as SNG400-2.5

- Q: What are the considerations for geotextile selection in railroad projects?

- There are several key considerations for geotextile selection in railroad projects. Firstly, the geotextile must have sufficient strength and durability to withstand the heavy loads and constant vibrations associated with train traffic. Additionally, it should have good filtration properties to prevent the migration of fine particles into the subgrade, which could lead to instability and settlement issues. The geotextile should also be resistant to degradation from environmental factors such as UV exposure and chemical exposure from ballast materials. Finally, the geotextile should be easy to install and maintain, ensuring a cost-effective and efficient solution for the railroad project.

- Q: How are geotextiles made?

- Geotextiles are made by weaving or knitting synthetic fibers together to form a fabric that is durable, permeable, and resistant to various environmental conditions. These fibers are typically made of materials such as polyester or polypropylene, which undergo a manufacturing process that includes extrusion, spinning, and heat treatment. The resulting fabric is then often coated or laminated to enhance its performance and functionality in various applications, such as soil stabilization, erosion control, and drainage systems.

- Q: What is the difference between polypropylene geotextile, polypropylene geotextile and polyester geotextile

- The raw material is not the same as the clothes have the same cotton polyester tea is the same characteristics of the characteristics of acid-resistant polyester anti-purple better look at where to see where the 4935 penguins

- Q: What are the factors to consider when selecting geotextiles for a project?

- Some factors to consider when selecting geotextiles for a project include the required strength and durability of the material, the desired permeability for water flow, the appropriate weight or thickness for the specific application, the compatibility with the soil or aggregate materials, the resistance to UV degradation, and the cost-effectiveness of the product. Additionally, factors such as installation and maintenance requirements, as well as any specific project constraints or regulations, should also be taken into account when making a selection.

- Q: How do geotextiles help in preventing shoreline erosion?

- Geotextiles help in preventing shoreline erosion by acting as a barrier against soil erosion caused by water movement. They are placed along the shoreline to stabilize the soil, reduce wave energy, and prevent sediment from being washed away. The geotextiles trap sediment and allow water to pass through, which helps to build up and maintain the beach or shoreline, ultimately protecting it from erosion.

- Q: 250 grams of two cloth a film 0.8 thick geotextile what price

- 250 grams of two cloth a film 0.8 thick geotextile per square meter between about 10 yuan -13 yuan, the current price is the lowest in recent years.

- Q: Can the geotextile of the filter layer be constructed?

- Hello, you can construction, I am specializing in the production of geosuction impermeable materials, a professional welding construction team, the most cost-effective, wish smooth

- Q: How do geotextiles contribute to the performance of geogrid-reinforced slopes?

- Geotextiles play a crucial role in enhancing the performance of geogrid-reinforced slopes. They provide separation and filtration functions by preventing the mixing of different soil layers and allowing water to drain through while preventing the loss of fine particles. This helps to maintain the integrity and stability of the slope, reducing the risk of erosion and soil movement. Additionally, geotextiles act as a barrier to vegetation growth, minimizing the potential damage caused by roots. Overall, geotextiles significantly contribute to the long-term effectiveness and durability of geogrid-reinforced slopes.

Send your message to us

Geotextile Filter Fabric Home Depot - Geomembrane Type HDPE LDPE Material

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords