Geomembrana Textil HDPE Geomembrane for Lake Liners - EVA, HDPE, LLDPE, PVC, LDPE Materials

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description Of EVA,HDPE,LLDPE,PVC,LDPE Material HDPE geomembrane:

| Type:HDPE geomembrane |

| Material: High-density polyethyle |

| Thickness:0.1mm~3.0mm |

| Roll width:1m~8m Roll length:50m~100m |

| Color:Black or at your request |

| Density: 0.94g /cm3 |

| Temperature range: -60oC -- +60oC |

| Life time: more than 50 years |

| Executive standard: GB/T 17643-2011 |

Main Features of EVA,HDPE,LLDPE,PVC,LDPE Material HDPE geomembrane:

1.Long life, anti-aging, roof material can be more than 20 years, underground can be more than 50 years.

2. Good tensile strength, high elongation.

3. Good high/low temperature flexibility

4.Easy to construct, no pollution.

5. Good anti-corrosive ability, can be used in special area

6.Various colors are available

Specifications of EVA,HDPE,LLDPE,PVC,LDPE Material HDPE geomembrane:

NO |

Item | Value | ||||||

| 0.75mm | 1.00mm | 1.25mm | 1.50mm | 2.00mm | 2.50mm | 3.00mm | ||

| 1 | Density (g/cm2) | 0.939 | ||||||

| 2 | Tensile propeties | |||||||

| Yield strength (N/mm) | 11 | 15 | 18 | 22 | 29 | 37 | 44 | |

| Break strength (N/mm) | 20 | 27 | 33 | 40 | 53 | 67 | 80 | |

| Yield elongation (%) | 12 | |||||||

| Break elongation (%) | ≥450 | |||||||

| 3 | Tear resistance (N) | 93 | 125 | 156 | 187 | 249 | 311 | 374 |

| 4 | Puncture resistance (N) | 240 | 320 | 400 | 480 | 640 | 800 | 960 |

| 5 | Stree crack tensistance (h) | ≥1500 | ||||||

| 6 | Carbon black | |||||||

| Carbon black content (%) | 2.0-3.0 | |||||||

| Carbon black dispersion | Carbon black dispersion (only near spherical agglomerates)fo r10 different | |||||||

| views 9 in categories 1 or 2 and 1 in category3 | ||||||||

| 7 | Oxidative induction time(OIT) | |||||||

| Standard OIT(min) | 100 | |||||||

| High pressure OIT(min) | 400 | |||||||

| 8 | Oven aging at 85°C | |||||||

| Standard OIT-% retained after 90 days (%) | 55 | |||||||

| High pressure OIT-% retained after 90 days (%) | 80 | |||||||

| 9 | UV Resistance | |||||||

| Standard OIT retained after 1600 hrs (%) | 50 | |||||||

| High pressure OITretained after 1600 hrs (%) | 50 | |||||||

| 10 | Low tempreture impact brittle property at -70°C | Pass | ||||||

| 11 | Premeability ( g.cm/(cm2).Pa) | ≤1.0×10-13 | ||||||

| 12 | Dimensional stability (%) | ±2 | ||||||

Applications of EVA,HDPE,LLDPE,PVC,LDPE Material HDPE geomembrane:

1.Prevent leakage disposal in waste burying field or waste water or waste dregs disposing field,river bank,lake dam ,mine remainings ,reservior,tunnel,liquid storage ,pool(pit,mine)

2.Preventing leakage in subway ,basement,tunnel ,hole

3.Anti-solt leakage in roadbed and other groundtill

4.The plane direction laying of dam ,the vertical direction laying fou groundtill ,used in the construction fence and waste material field

5.Used in seawater or freshwater feed field

6.Used in groundtill of road,highway ,railway and waterproof layer of swelling clay and wet collapsed loess

Preventing leakage on rooftop.

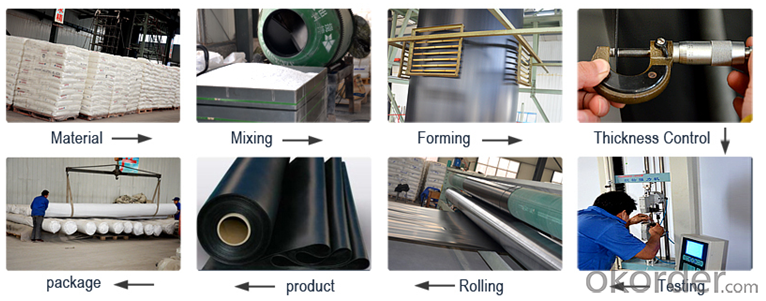

IMages of EVA,HDPE,LLDPE,PVC,LDPE Material HDPE geomembrane:

FAQ:

1. Do you supply free samples for customers?

Yes,we will supply free samples for you.Please send your address for us.

2. How Many years experience do you have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q: What are the advantages of using geomembranes in waste containment systems?

- There are several advantages of using geomembranes in waste containment systems. Firstly, geomembranes act as a reliable barrier, preventing the leakage of hazardous substances from waste sites into the surrounding environment. They also help in controlling the migration of contaminants, ensuring protection for soil, groundwater, and nearby ecosystems. Additionally, geomembranes are durable and resistant to various chemicals, UV radiation, and punctures, making them a long-lasting solution for waste containment. Moreover, their flexible and customizable nature allows for easy installation and adaptability to different site conditions. Lastly, the use of geomembranes can significantly reduce construction time and costs compared to traditional methods, making them a cost-effective option for waste containment systems.

- Q: Which is better for ceramic film and organic film ?

- Each have their own advantage, because the two are different in nature

- Q: What is the coated glass stick membrane?

- Coated glass is cheap, but the function of which is not as much as that of film glass. Coated glass not only can protect privacy, but film glass not only can protect privacy but also has functions of heat insulation, anti-explosion, ultraviolet rejection (Heat insulation function can play an air-conditioning role which saves on electricity bills. Anti-explosion function can prevent broken glass from hurting families for it will stick together when the glass is broken and splashed. Ultraviolet rejection function can protect our skin, and prevent furniture and curtains from fading). On the other hand, stick membrane can play a decorative role, there is no glare when seeing through glass with stick membrane (there is eye strain and glare when seeing through glass with no stick membrane). While the film glass is not like that.

- Q: What are the specifications of plastic film

- The measurement of thickness and refractive index of dielectric thin film by ellipsometry is widely used in modern science and technology. Therefore, the measurement of thin film technology has been greatly developed, ellipsometry is one of the most accurate methods of measuring thin film developed since 70s with the wide application of electronic computers. Ellipsometry measurement has the following characteristics: Can measure a very thin film (1nm), and the accuracy is very high, 1-2 orders of magnitude higher than the interference method. Is a non destructive measurement, without special preparation of samples, nor damage to the sample, compared to other precision methods: Such as weighing method, quantitative chemical analysis method is simple and convenient. The thickness, refractive index and absorption coefficient of the film can be measured simultaneously. So it can be used as an analytical tool. Is very sensitive to some surface structure, surface process and surface reaction. Is a method of studying surface physics.

- Q: What is the working principle of the electric heating film

- The hot air passage structure is adopted to enhance the heat transfer mode, and the heat starting will be faster, and the temperature of the air outlet is more than 100 in 3 minutes, but it will imeediately cool off. Because the electric heating film itself is oxidation free, and its service life can be in 100 thousand hours, and at the same time it has the characteristics of small size, beautiful appearance, etc., belonging to the generation of the electric heating device. Thermosyphon tube heater is a new electric?heater sold this year, it uses the two-phase closed thermosyphon "as the heat source, which heats fastly with high thermal efficiency. It does not give out light, produce no flame, not afraid of water and water vapor corrosion. It is suitable for ordinary room and bathroom

- Q: What are the differences between the geomembrane and the geotextile?

- The geomembraneis is impermeable material made of plastic film as anti-seepage material, and composites with non woven fabric. Its anti-seepage property mainly depends on the anti-seepage property of plastic film. At present, the domestic and foreign anti-seepage plastic films mainly include polyvinyl chloride (PVC) and polyethylene (PE) and EVA (ethylene / vinyl acetate copolymer), design of the tunnel also used ECB (blending geomembrane of ethylene-acetic acid-ethylene modified asphalt), which is a kind of macromolecular chemistry of flexible material, and it features a smaller proportion, good extensibility, high adaptation to the deformation, corrosion resistance, low temperature resistance, and good frost resistance. The geotextileis a permeable composite material made of synthetic fibers, which are made by needling or knitting; its physical structure is multi-layer cloth membrane. Finished products are cloth-shaped, the general width is 4-6 meters, length is 50-100 meters. The geotextile is divided into woven geotextile and non-woven geotextile. The geotextile has the characteristics of excellent filtration, drainage, isolation, reinforcement and protection, with light weight, high tensile strength, good permeability, high temperature resistance, freezing resistance, aging resistance and corrosion resistance.

- Q: What are the considerations for geomembrane installations in areas with high snow loads?

- When considering geomembrane installations in areas with high snow loads, several key factors must be taken into account. Firstly, the design of the geomembrane system should be robust enough to withstand the weight and pressure exerted by the snow load. This may require thicker or reinforced geomembrane materials, as well as additional support structures such as geotextiles or geogrids. Secondly, proper site preparation is crucial. The installation area should be cleared of any debris or obstacles that could potentially damage the geomembrane or impede its performance under the snow load. Additionally, the site should be properly graded to ensure adequate drainage and prevent the formation of snow accumulations or ice dams that could put excessive pressure on the geomembrane. Another consideration is the choice of anchorage method. The geomembrane should be securely anchored to prevent any uplift or movement caused by snow accumulation or wind. This may involve using anchor trenches, ballast systems, or other appropriate anchoring techniques. Furthermore, the choice of geomembrane material should take into account its resistance to cold temperatures, freeze-thaw cycles, and potential damage caused by ice or snow removal activities. It is important to select a geomembrane material that can withstand the specific climatic conditions of the area and maintain its integrity throughout the winter season. Lastly, regular inspection and maintenance are essential for geomembrane installations in high snow load areas. Periodically checking for any signs of damage, such as tears, punctures, or stress points, and promptly addressing them can help prevent further deterioration and ensure the longevity of the geomembrane system. In summary, considerations for geomembrane installations in areas with high snow loads include robust design, proper site preparation, secure anchorage, selection of suitable geomembrane material, and regular inspection and maintenance.

- Q: How to pave the waterproof membrane in the interior finish

- It should first deal with the base: remove the original decoration materials, and clean up the capping mass and cement. It requires smooth and dry surface. Paving waterproof paint: brush a layer of modified asphalt and lay a layer of glass fibre cloth on the base of waterproofing process, and then repeat brushing, finally brushing the paint on the second layer of glass fibre cloth, the waterproof processing is finished. Waterproof coating shall be painted in uniform, glass wool cloth and waterproof layer must be closed tightly, it can not have the phenomenon of brushing leakage, bulking and shedding, otherwise it will affect the waterproofing effect. If you select the polyurethane waterproofing paint, it should not usually add the glass wool cloth, just repeatedly brushing 2 to 3 times as long as you can. Explain: Note that see the prompt part of the page to do the "closed water" test: Closed water test is an important test method to test the water quality of indoor. After the waterproof project is done, seal the door and the water inlet, fill with water in the room to reach a certain level, if there is no significant decline in the liquid level within 24 hours, that is qualified. And then do a layer of protective layer: Do a layer of cement mortar protection layer on the waterproof coating layer, pay attention not to damage the waterproof coating layer. After the cement mortar protective layers dry up, you can pave the wall floor tile or brush the paint on it, and then do the normal decoration.

- Q: The geomembrane is used which structure of seepage-proof system? What are the materials of the anti-seepage system?

- Cement concrete surface. Seepage-proof material of about 30cm protective layer can ensure the waterproof and seepage prevention of geomembrane.

- Q: Chernozem, reservoir foundation, slope treatment (geomembrane reservoir) methods. The more detailed, the better. And the best with pictures. . .

- 1, first flatten and tamp original drawing 2, dig 400mm × 600mm ditch at the bottom 3, brush slope - engineering or mechanical side slope brush design 4, pave 50mm-long and 0.8 thick washed-out sand 5, pave geomembrane 6, apply 30mm cement mortar on geomembrane door 7, assembling?reinforcement on cement mortar surface layer 8, asphalt crack pouring

Send your message to us

Geomembrana Textil HDPE Geomembrane for Lake Liners - EVA, HDPE, LLDPE, PVC, LDPE Materials

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords