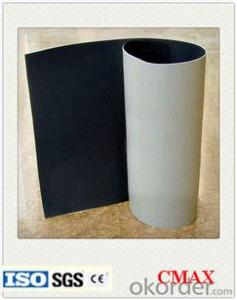

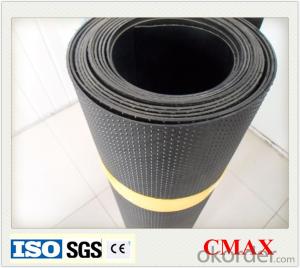

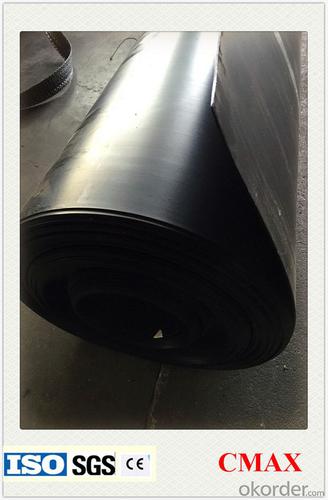

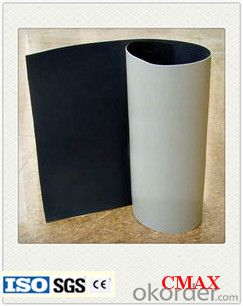

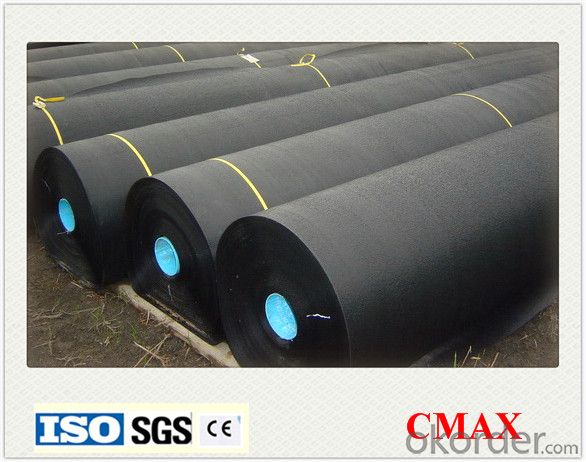

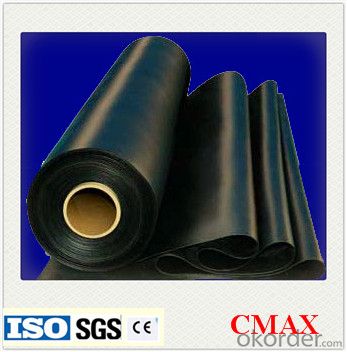

Geomembrana Hp 30 - LDPE/HDPE/LLDPE Geomembrane with Thickness 0.5mm

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

LDPE/HDPE/LLDPE Geomembrane 100% Virgin Material

Description

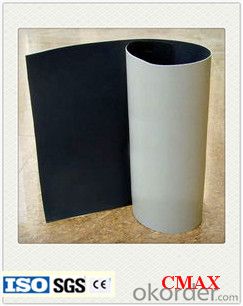

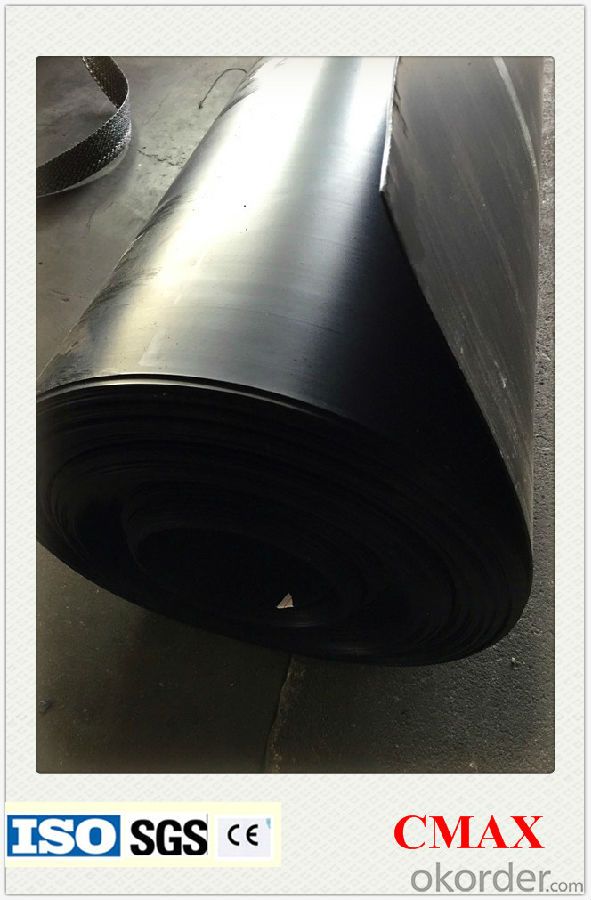

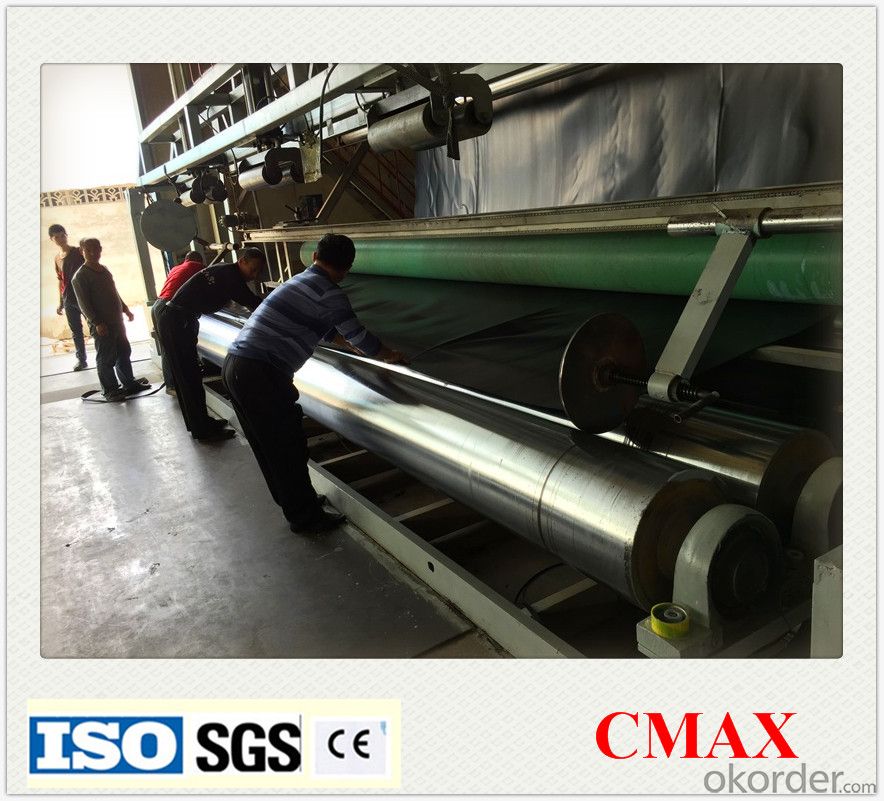

Geomembrane is made from LDPE, LLDPE, HDPE, EVA resin and additives such as antioxidant, carbon black, master batch etc with the method of 1 layer extrusion and 3 layers co-extrusion in high temperature.

Specification

1. Thickness: 0.1mm-3.0mm

2. 4m-9m in roll width, the length as clients' request.

Property:

Excellent waterproof, heat preservation, easy for welding, chemical and UV resistance.

Application:

1.landfill,sewage or control the waste residue seashores seepage.

2.Lake dam,tailings dams,sewage dam and reservoir,channel,storage of liquid pools(pit,ore)

3.The subway ,tunnel,anti-seepage lining of basement and tunnel.

4.To control the roadbed and other foundation saline seepage.

5.Dike,the front of the sam foundation seepage prevention bedding,level of vertical impervious layer , construction cofferdam,waste field.

6.Seawater,freshwater fish farms.

7.Highway,the foundations of the highway and railway;the expansive soil and collapsible loess of the waterproof layer.

8.Anti-seepage of roofing

FAQ:

Q1: What is your minimum order quantity?

A:The minimum order quantity is 5000 sqm.

Q2:What is your payment terms?

A: T/T,Western Union,Paypal,L/C...

Q3:What is your delivery time?

A:Production time usually costs 2-20 days.

Waiting to cooperate with you!

- Q: Why composite geo-membrane can not be used in underground garage?

- Composite geo-membrane was invented in China, applied in the The South-to-north Water Diversion Project with good anti-seepage effect. While there are no composite geo-membrane in foreign countries. It has also been widely used in subway?tunnel and other underground constructions. Of course, it can be used in underground garage , but you must choose the appropriate specifications. It is recommended to use 300g/1.0mm/300g composite geo-membrane. The following are the details. Composite geo membrane is geotechnical impermeable material made of plastic film as anti-seepage material and non-woven fabrics. Its waterproof performance mainly depends on the performance of plastic film. Impermeable plastic film at home and abroad are mainly polyvinyl chloride (PVC) and polyethylene (PE), which are Polymer chemistry flexible material with smaller proportion, good extensibility and high?adaptability?to the?deformation. Corrosion resistance, low temperature resistance, good anti-frost?property. The main mechanism is to block earth dam leakage passage by imperviousness of plastic film and bear hydraulic?pressure and adapt to deformation of dam with greater tensile strength and elongation. Non-woven geotextile is also a kind of macromolecule staple fibre chemical material shaped through acupuncturing or hot sticking, having high tensile strength and extensibility. Combined with plastic film, it can not only increases the tensile strength and anti-puncture ability of plastic film, but also increase the friction coefficient of contact surface and make the composite geo-membrane and packaging layer stable as the non-woven fabrics surface becomes rough. At the same time, they have good corrosion resistance to bacteria and chemical action, not afraid of acid, alkali, salt erosion, high seepage coefficient.

- Q: What are the functions of grease for film sleeve?

- Functions of fuser film: toner image transferred to the paper must heated so as to soften the resin in toner and make it firmly fix on the paper, fuser film plays the role of fixing roller as above. Why do people use fuser film to replace fixing roller? Printers are generally power on all day, especially multi-function printers are in service for 24 hours; but the fixing roller has a large thermal inertia and power consumption, internal heat is not easy to give off. In order to reduce the preheat standby time and achieve zero start, fixing roller is replaced razor-thin film.

- Q: What is electrothermal transparent film?

- Electrothermal?film heating system is different from dot mode heating system such as radiator, air-conditioning and heating radiator, from the streamlined heating system such as heating cable and from the face heating system such as LC supply heating high-tech products made by aerospace flight technology. It takes electrothermal?film as heating element to transfer heat into the air by radiation. Human body and objects can be warmed first. It is better in resultant effect compared with traditional convection heating method. Low temperature radiation electrothermal film heating system is composed of power?supply, temperature?controller, adapting piece, insulating layer, electrothermal?film and finish?coat. Electric energy can be converted to heat energy by electrothermal film.

- Q: What are the technical parameters of seepage-proof geomembranes?

- serial number item indicator common environmental protection 1 thickness mm 0.2 to 4 2 width m 2.5 to 8 3 tensile strength (vertically and horizontally) MPa≥17 ≥25 4 breaking elongation rate (vertically and horizontally) % ≥450 ≥550 5 angle tear strength N/mm ≥80 ≥110 6 carbon black content % 2.0 to 3.0 2.0 to 3.0 7 resistance to environment stress cracking F20 ≥1500 8 low-temperature impact in -70℃ approved 9 oxidative inductive time in 200℃ ≥20

- Q: Are geomembranes resistant to microbial growth?

- Yes, geomembranes are generally resistant to microbial growth. The impermeable nature of geomembranes and their resistance to degradation make it difficult for microorganisms to grow on their surface. However, it is important to note that the presence of moisture, nutrients, and certain environmental conditions can still lead to microbial growth over time.

- Q: Can geomembranes be customized for specific projects?

- Yes, geomembranes can be customized for specific projects. They can be tailored to meet specific size, shape, and material requirements, ensuring they are suitable for the specific conditions and needs of the project. This customization allows for optimal performance and longevity of the geomembrane in various applications such as landfill liners, mining containment, and water storage.

- Q: How do geomembranes help in preventing seepage?

- Geomembranes are impermeable barriers made of synthetic materials that are used to prevent seepage in various applications. These membranes create a physical barrier that restricts the flow of water or other fluids through the underlying soil or structure. By preventing seepage, geomembranes ensure that contaminants, such as chemicals or pollutants, do not migrate into the surrounding environment. Additionally, geomembranes also provide stability and reinforcement to the underlying structure, further enhancing their ability to prevent seepage.

- Q: Are geomembranes resistant to punctures from construction equipment?

- Yes, geomembranes are designed to be highly resistant to punctures from construction equipment.

- Q: What are the construction norms of composite geomembrane?

- The composite geomembrane construction process: One, base surface excavation, two, geomembrane pavement, three. align the welding seams, Four. welding, five. site inspection, Six , repair, seven,reinspection, eight, backfill soil

Send your message to us

Geomembrana Hp 30 - LDPE/HDPE/LLDPE Geomembrane with Thickness 0.5mm

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords