Geogrids for Velocity Slopes - Polyester Geogrids with High Tensile Strength and Best Quality

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction:

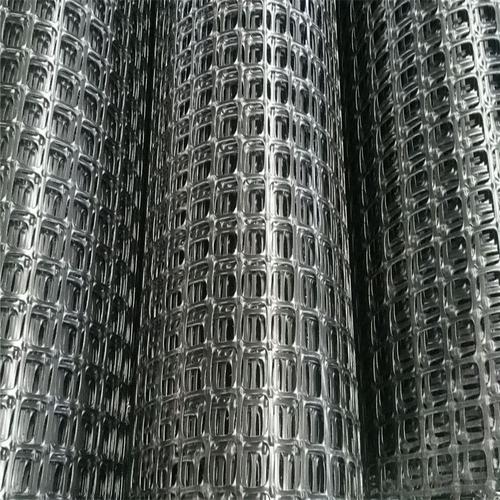

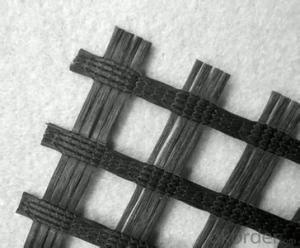

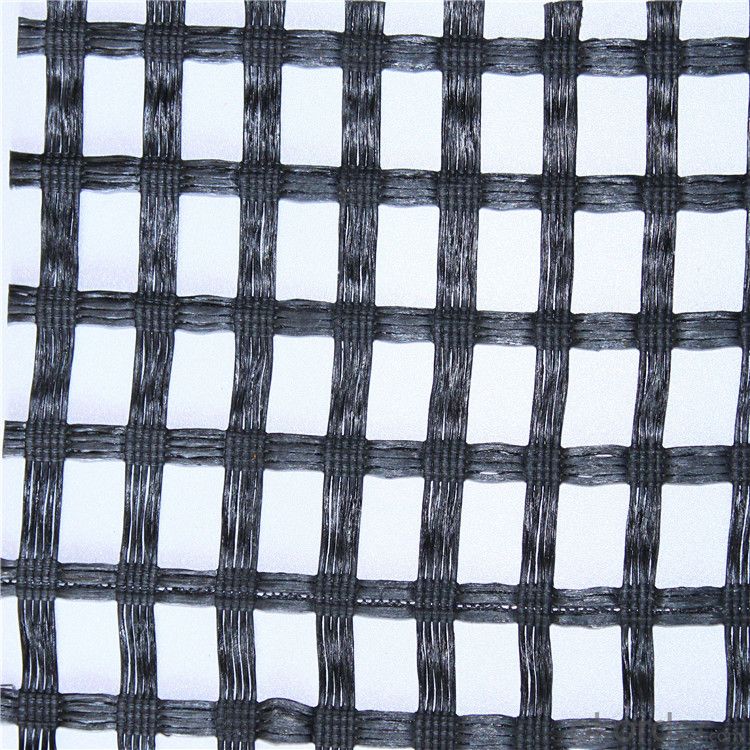

Polyester geogrid is a new kind of favorable earthwork base material to strength the road surface and roadbed, which composed of high strength polyester yarns coated with an inorganic sizing agent.

Features:

1) High tensile strength

2) High tear-resistant

3) Strong combination with gravel and soil

Specifications :

Mesh size(mm) | 25.4×25.4 Or 12.5×12.5 | |||||

Breaking strength ≥(KN/m) | Warp direction | 30 | 50 | 80 | 100 | 120 |

Across warp | 30 | 50 | 80 | 100 | 120 | |

Elongation at break ≤(%) | Warp direction | 3 | ||||

Across warp | 3 | |||||

Elasticity modulus(GPA) | 67 | |||||

Thermal tolerance | -100~280℃ | |||||

Width | 1~6m | |||||

Function:

This product is made by weaving and covering fiberglass filament. It is featured by high vertical and horizontal tensile

strength, low unit extension, high flexibility, and favorable high and low temperature resistance. The products after

surface covering own the favorable property of alkali resistance and aging resistance.

It is used widely to increase the asphalt road surface, concrete road and roadbed (both soft and hard road surfaces).

Compared with the traditional road surface, it reduces the cost, prolong the service life, and avoid the reflection road

crackle.

This product is also used to strengthen the soft land, such as railway, airport, irrigation work, and dyke, etc, and the

roadbed 。

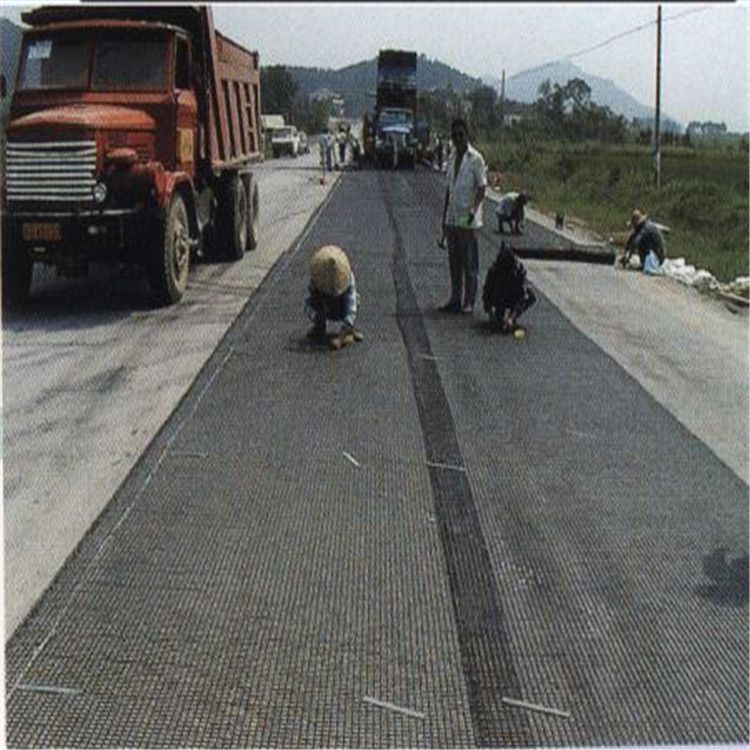

Image of Polyester Geogrid

- Q: Geotextile manufacturers which good? Where is the best geotextile, geotextile manufacturers

- Nonwoven and woven composite geotextiles:The non-woven fabric is woven with the polypropylene filament woven fabric, and the non-woven fabric is woven with the plastic braiding.

- Q: Can geogrids be used in shoreline protection applications?

- Yes, geogrids can be used in shoreline protection applications. Geogrids are often employed in shoreline protection projects to stabilize and reinforce the soil, preventing erosion and minimizing the impact of waves and water currents.

- Q: Are there any limitations or disadvantages of using geogrids?

- Yes, there are some limitations and disadvantages of using geogrids. Firstly, geogrids are not suitable for all types of soil conditions and may not be effective in areas with highly cohesive or expansive soils. Secondly, geogrids have limited tensile strength and may not be able to withstand heavy loads or extreme environmental conditions. Additionally, geogrids require proper installation techniques for optimal performance, which may increase the overall project cost. Lastly, regular maintenance and inspection are necessary to ensure the long-term effectiveness of geogrids, adding to the maintenance expenses.

- Q: What are the factors that affect the quality of glass fiber reinforced plastic grid

- The first is glass fiber. Glass steel fiber can improve the tensile strength and the elastic modulus of FRP pultruded grating plate, but also can reduce shrinkage, improve the heat deformation temperature and low temperature impact strength, therefore is glass steel grille pultrusion cover the main load-bearing part.

- Q: Are geogrids resistant to aging?

- Yes, geogrids are generally resistant to aging. They are designed to withstand long-term exposure to environmental factors such as UV radiation, chemicals, and temperature variations, ensuring their durability and longevity.

- Q: How to ensure the quality of geogrid laying?

- The geogrid laying quantity and not according to the design, inspection group of misrepresentation. "Said simply is not according to the standard of laying geogrid, geogrid using standard reasons for the decline, Jerry was to" per square meter can save about 20 Fen, part of the investment funds also led to this events. The quality problems of railway construction, which relates to the future railway service life and quality

- Q: Can geogrids be used for reinforcement in railway tracks?

- Yes, geogrids can be used for reinforcement in railway tracks. Geogrids are often used to improve the stability and load-bearing capacity of railway tracks by providing additional reinforcement and preventing soil movement. They can help distribute loads more evenly, reduce settlement, and improve overall performance and longevity of the tracks.

- Q: Can geogrids be used in floating road construction?

- Yes, geogrids can be used in floating road construction. Geogrids are commonly employed in road construction projects to improve the stability and load-bearing capacity of the road structure. When used in floating road construction, geogrids help to distribute and reinforce the load, reducing the pressure on the underlying soil or subgrade. This ensures better performance and longevity of the road, even in challenging or soft soil conditions.

- Q: What are the benefits of using geogrids in construction projects?

- Geogrids offer several benefits in construction projects, including increased soil stability, improved load distribution, and enhanced overall structural integrity. These materials reinforce and stabilize the soil, preventing erosion and reducing the risk of slope failure. Geogrids also help distribute loads more evenly, reducing stress on the construction materials and extending their lifespan. Additionally, geogrids can be cost-effective as they often require less excavation and backfill material, saving time and resources during construction.

- Q: How do geogrids help in reducing the need for excavation and replacement of poor soils?

- Geogrids help in reducing the need for excavation and replacement of poor soils by providing reinforcement and stabilization to the soil, improving its load-bearing capacity. This prevents excessive settlement and movement of the soil, reducing the need for costly excavation and replacement.

Send your message to us

Geogrids for Velocity Slopes - Polyester Geogrids with High Tensile Strength and Best Quality

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords