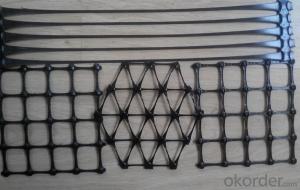

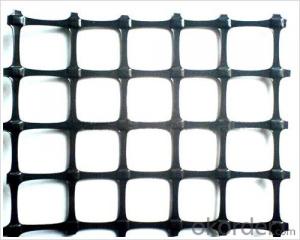

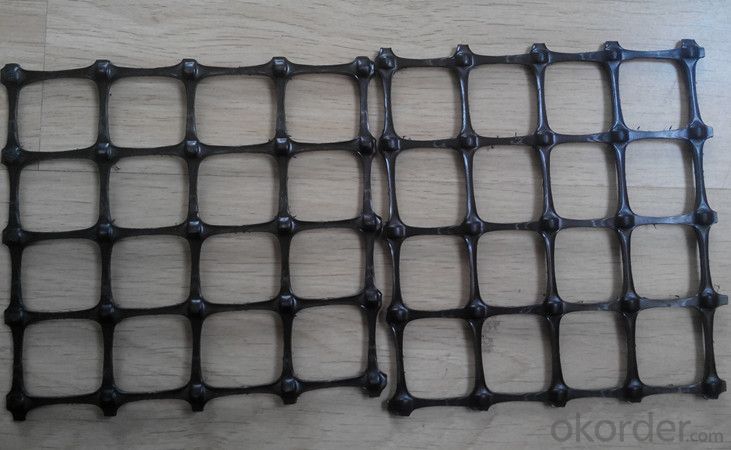

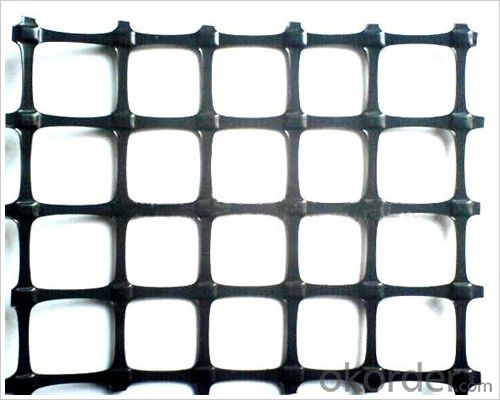

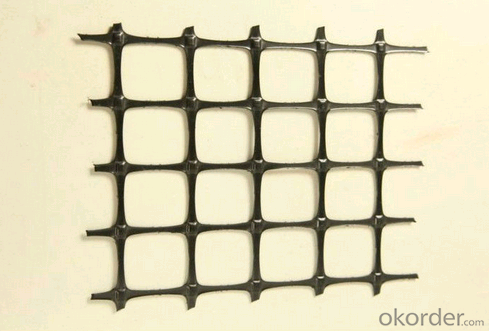

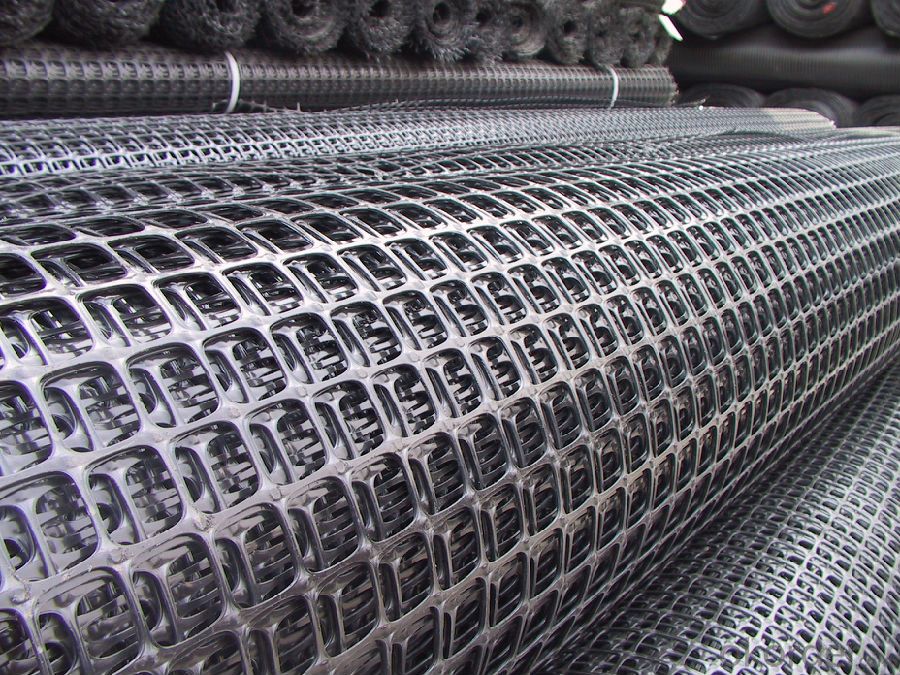

Geogrids for Access Routes - Steel Plastic Welding Geogrid

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Applications:

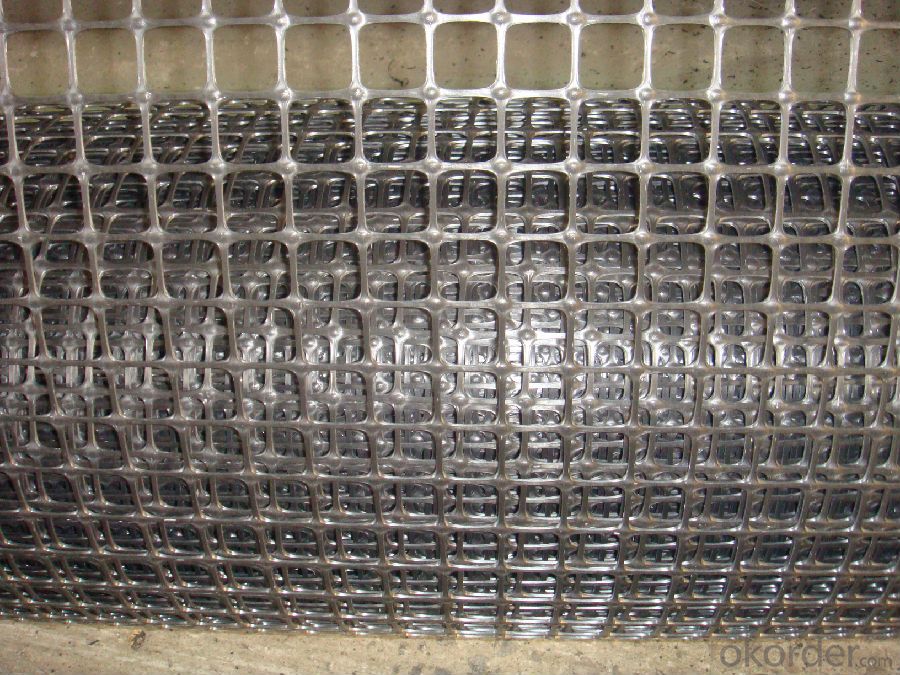

Make reinforce treatment for various kinds of soft soil foundation to evenly distribute load stress and reduce uneven settlement, not easy to generate static electricity, and flammability property good in the coal mine. It is easy to wash coal.

Used in highway, railway, port, airport and municipal project. Support in the recovery working face of coal mine and roadway in the coal mine.

Index Properties | Test Method | Unit | GG1515 | GG2020 | GG3030 | GG4040 |

MD TD | MD TD | MD TD | MD TD | |||

Polymer | -- | -- | PP | PP | PP | PP |

Minimum Carbon Black | ASTM D 4218 | % | 2 | 2 | 2 | 2 |

Tensile Strength@ 2% Strain | ASTM D 6637 | Kn/m | 5 5 | 7 7 | 10.5 10.5 | 14 14 |

Tensile Strength@ 5% Strain | ASTM D 6637 | Kn/m | 7 7 | 14 14 | 21 21 | 28 28 |

Ultimate Tensile Strength | ASTM D 6637 | Kn/m | 15 15 | 20 20 | 30 30 | 40 40 |

Strain @ Ultimate Strength | ASTM D 6637 | % | 13 10 | 13 10 | 13 10 | 13 10 |

Structural Integrity | ||||||

Junction Efficiency | GRI GG2 | % | 93 | 93 | 93 | 93 |

Flexural Rigidity | ASTM D 1388 | Mg-cm | 700000 | 1000000 | 3500000 | 10000000 |

Aperture Stability | COE Method | mm-N/deg | 646 | 707 | 1432 | 2104 |

Dimensions | ||||||

Roll Width | -- | M | 3.95 | 3.95 | 3.95 | 3.95 |

Roll Length | -- | M | 50 | 50 | 50 | 50 |

Roll Weight | -- | Kg | 39 | 50 | 72 | 105 |

MD denotes Machine direction. TD denotes transverse direction. | ||||||

| Packaging Details: | according to your need |

| Delivery Detail: | 7days |

FAQ

Q:Can you provide a sample for us?

A:Yes,We can send free samples,but customer need to pay the freight.

Q:What is your minimum order quantity?

A:The minimum order is negotiable.

Q:What is your payment terms?

A: T/T or L/C

Q: What is your delivery time?

A:Production time usually cost 7-15 days.

Q: Why we choose you?

We have up to 15 years experience of geogrid manufacture. best quality of product is guaranteed!

- Q: Can geogrids be used in stabilization of mine tailings ponds?

- Yes, geogrids can be used in the stabilization of mine tailings ponds. Geogrids are commonly used in civil engineering for soil stabilization and reinforcement. They can provide strength and stability to the soil, preventing erosion and minimizing the risk of slope failure. In the context of mine tailings ponds, where the soil is often unstable and prone to erosion, geogrids can be an effective solution for stabilizing the area and preventing environmental hazards.

- Q: Bi directional plastic geogrid is suitable for engineering

- Slope protection, wall reinforcement, large airport, parking lot

- Q: Can geogrids be used in coastal erosion control projects?

- Yes, geogrids can be used in coastal erosion control projects. Geogrids are commonly used in these projects to stabilize and reinforce coastal slopes, preventing erosion and maintaining the integrity of the coastline. They can help to reduce wave energy and control sediment movement, making them an effective solution for coastal erosion control.

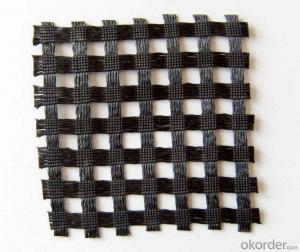

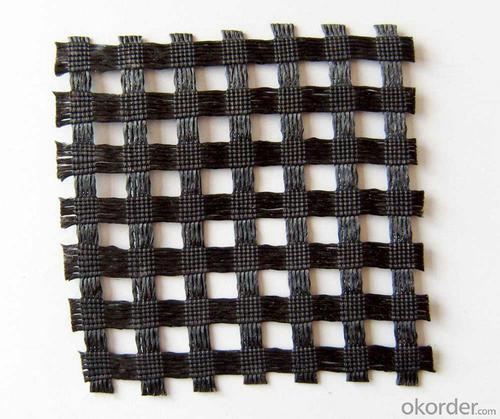

- Q: Polypropylene geogrid

- You said the polypropylene geogrid, generally only two-way plastic geogrid and one-way plastic geogrid is polypropylene material

- Q: What is the vertical spacing of Geogrid

- Refers to the size of the geogrid mesh holeSpecific attention is not clear, the banner of Chang Chang official CafeThere's something you're looking forGrille generally by the vertical and horizontal staggered from the simple meaning of space can also be understood that the size of the lattice gap.

- Q: What are the factors that affect the creep behavior of geogrids?

- There are several factors that can affect the creep behavior of geogrids. These include the type and quality of the geogrid material, the load applied to the geogrid, the duration of the load, the temperature and moisture conditions, and the installation and construction methods used.

- Q: Are geogrids resistant to biological clogging?

- Yes, geogrids are generally resistant to biological clogging. They are typically made from synthetic materials, such as polypropylene or polyester, which are not easily degraded by biological organisms. This resistance to clogging allows geogrids to maintain their structural integrity and effectiveness in various soil stabilization and reinforcement applications.

- Q: What is the effect of installation spacing on geogrid behavior?

- The effect of installation spacing on geogrid behavior is that it can impact the overall performance and effectiveness of the geogrid. Proper installation spacing ensures proper load distribution and reinforcement, allowing the geogrid to effectively stabilize the soil and prevent deformation or failure. Inadequate spacing can lead to localized stress concentrations, reduced load capacity, and potential geogrid failure. Therefore, the spacing between geogrid installations is an important factor to consider in order to achieve optimal performance and long-term stability.

- Q: Can geogrids be used in road widening projects?

- Yes, geogrids can be used in road widening projects. Geogrids are commonly used in road construction and rehabilitation projects to enhance the stability and load-bearing capacity of the roadway. They can help to distribute loads, increase the overall strength of the pavement, and reduce the potential for cracking and rutting. When widening a road, geogrids can be installed to reinforce the new sections of pavement and ensure the longevity and durability of the widened road.

- Q: How do geogrids improve the performance of reinforced soil structures?

- Geogrids improve the performance of reinforced soil structures by providing tensile strength and stabilizing the soil, preventing its movement and potential failure. The geogrids act as reinforcements that distribute the applied loads more evenly, reducing the stresses on the soil and improving its overall stability. Additionally, geogrids enhance the bearing capacity of the structure, increase its resistance to settlement, and minimize the potential for deformation or displacement.

Send your message to us

Geogrids for Access Routes - Steel Plastic Welding Geogrid

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords