Geogrids Que Son - Geogrid 160kn/160kn with High Quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Product Description:

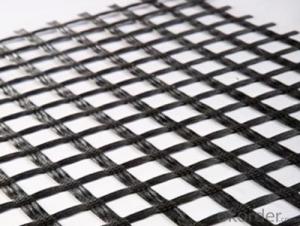

Type: Geogrids

Place of Origin: Shandong, China (Mainland)

Material: Plastic-Steel, HDPE/PPModel Number: TGDG

Color: black etc.

Length: 50-100m (or at request)

SAMPLE: AVAILABLE

2. Product Characteristic:

1. Increase the bearing capacity of the roadbed and foundation and prolong their service life.

2. Prevent road surface and foundation from sinking or flawing, keep clean and beautiful ground surface.

3. Convenient construction saves time and labor, reduce mounting time and decrease maintenance expense.

4. Prevent culverts from flawing.

5. Enhance earth slope and prevent water loss and soil erosion.

6. Decrease underlayer thickness and save manufacturing cost.

7. Size & Specification

3.Specification :

Packaging Details: | Standard exporting package , or as your special request |

Delivery Detail: | within 10 days |

Specifications

Geogrid

1.Tensile strength: 15~100KN/M

2.Color:black and etc.

3.Material:PP/PE

4.Certification:CE/ISO9001,14001

4. Reference Picture:

- Q: How do geogrids improve the load-bearing capacity of soil?

- Geogrids improve the load-bearing capacity of soil by providing reinforcement and stabilization. They interlock with the soil particles, creating a stronger and more cohesive structure. This prevents the soil from shifting or settling, effectively distributing the load and increasing its overall strength.

- Q: Are geogrids suitable for reinforcement of steep slopes?

- Yes, geogrids are suitable for reinforcement of steep slopes. Geogrids are commonly used in geotechnical engineering to enhance the stability and strength of slopes by providing reinforcement and preventing soil erosion. They can effectively distribute the tensile forces within the soil, reducing the risk of slope failure and improving overall slope stability.

- Q: What is the meaning of the geogrid reinforced asphalt in the project list

- You are not me, I was the construction of geogrid manufacturers, generally used in the mygeogrid on the road of geogrid is fiberglass geogrid, in your compacted Subgrade after injection will then laying a layer or several layers of fiberglass geogrid, after paving asphalt, the operation process is this, geogrid and asphalt is two kinds of different products

- Q: What are the design guidelines for geogrid-reinforced structures?

- The design guidelines for geogrid-reinforced structures involve considering factors such as soil properties, design loads, and installation requirements. Some key guidelines include determining the appropriate geogrid material and strength based on the specific site conditions, ensuring proper connection between the geogrid and the surrounding soil or structures, designing for the anticipated loads and settlement, and following recommended installation techniques to ensure the effectiveness of the reinforcement system. Additionally, considering factors such as long-term durability, maintenance requirements, and environmental considerations are also important in designing geogrid-reinforced structures.

- Q: How do geogrids improve the stability of landfills?

- Geogrids improve the stability of landfills by providing reinforcement and support to the waste materials, preventing slope failure and maintaining the overall integrity of the landfill structure.

- Q: What are the testing methods for geogrids?

- Some testing methods for geogrids include tensile strength testing, creep testing, puncture resistance testing, and pullout testing. These methods help assess the mechanical properties and performance of geogrids in various applications such as soil stabilization and reinforcement.

- Q: How do geogrids enhance the performance of geotextiles?

- Geogrids enhance the performance of geotextiles by providing additional reinforcement and stability to the soil. They work by interlocking with the soil particles and distributing the applied loads more evenly, which helps to prevent soil erosion, improve load-bearing capacity, and increase the overall strength and durability of the geotextile system.

- Q: The geogrid is convenient for construction, time saving, labor saving, shorten the construction period and reduce maintenance cost.

- Fill enough paint to make it smooth.6, removal of leakage of tape. Then, note that all of the cracks have been properly repaired, with a fine composite material will be modified around the repair, so that it is as bright as new.

- Q: Glass fiber mesh cloth is mainly used in what place

- Main applications are widely used in

- Q: What kind of geogrid can meet the requirements

- Polypropylene single pull plastic grille TGDG80 meet the requirements

Send your message to us

Geogrids Que Son - Geogrid 160kn/160kn with High Quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords