GBF series fluorine plastic lining pipeline pump

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.GBF series fluorine plastic lining pipeline pump descriptions

GBF series fluorine plastic lining pipeline pump is made by fluorine plastic hot melt molding process, with particularly strong corrosion resistance of the new pipeline centrifugal pump. This pump impeller and motor straight via stent, choose bellows outer container type mechanical seal, shaft seal is stable and reliable, intuitive easy to adjust, hydraulic performance is superior, the suction uniform, over-current components using fluorine plastic materials(PEP, PFA ) manufacturing, decay resistance performance excellence.

Corrosion resistance, heat resistance, not aging, smooth operation, low noise, high efficiency, easy maintenance, long life and other advantages, widely used in acid and alkali, oil, chemical industry, electrolysis, electroplating, pickling, aluminum foil, rare earth, medicine, dyes, pesticides, flue gas desulfurization and dust removal, food, pharmaceutical and synthetic fiber industries.

Applicable temperature: 60℃~+150℃

2. Model sense

Ex: 50GBF-30

-50:Nominal diameter of inlet and outlet (mm)

-GBF:Fiourine plastic lining pipeline pump

-30:Pump head (m)

3. Design features

- The pump flow components application fluorine plastic hot melt moulding process combined into a whole, high mechanical strength;

- Has excellent corrosion resistance performance, transmission of all kinds of corrosive medium, such as acid, alkali, oxidant and organic solvent without damage;

-The pump is vertical structure, inlet and outlet diameter are the same, and is located in the center of a unified online, easy installation, use of a small area, the motor add a rainproof cover can be used outdoors;

- The impeller and motor direct dive, short axial dimensions, compact structure, smooth operation, high transmission efficiency, low noise and vibration;

- Shaft seal installed PTFE corrugated pipe mechanical seal, sealed and reliable, intuitive, and according to the characteristics of the media to provide a variety of materials friction pair selection, and has a wide application range;

- The use of the maintenance is convenient, only need to remove the pump body and the connecting frame fastening nut can be disassembled the rest, no need to remove the dynamic pipeline.

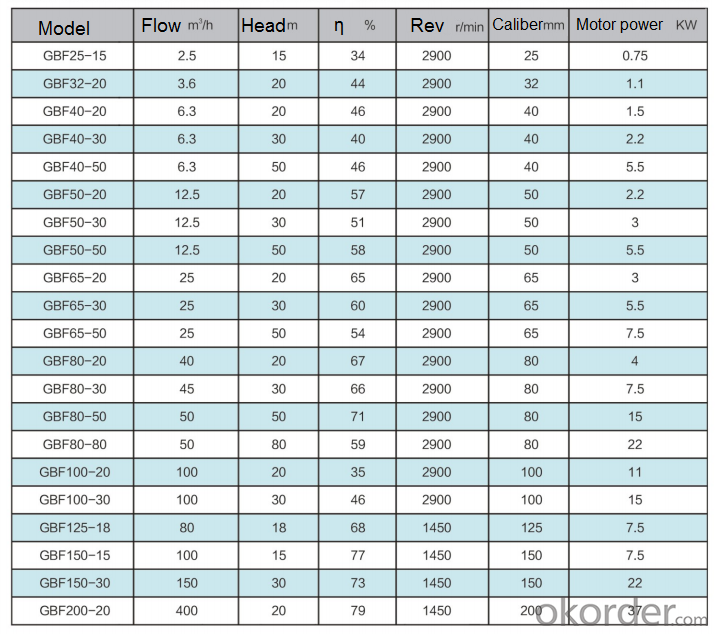

4. Technical parameters

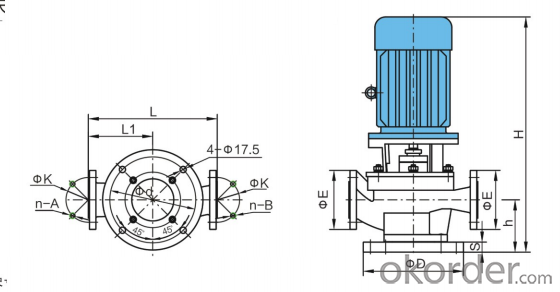

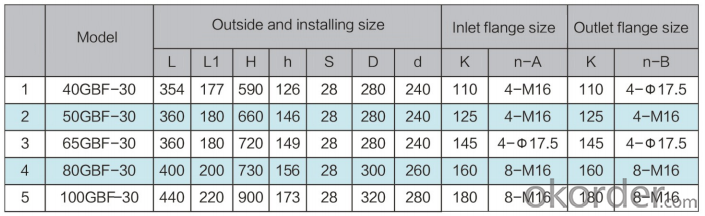

5. Install size / Flange size

- Q: How to adjust the flow of piston pump?

- For the swashplate valve controlled by the solenoid valve, the swashplate is in an angle with the cylinder body, so the plunger is reciprocating in the pump cylinder when the cylinder rotates. It goes from 0 degrees to 180 degrees, that is, to the upper plunger position, the plunger cylinder volume gradually increased

- Q: What are the meanings of the vacuum pump, the front pump and the main pump?

- In operation, the main gas extraction limit vacuum is achieved by the main pump, so we call it the main pump, which plays the main role of the pumpThe front pump is the pump that needs to be opened ahead of the main pump. It is called the pump before the main pump and the pump running the main pumpIf you don't understand, look at your signature and ask again

- Q: What is a water pump coupling device?

- The automatic coupling device of the water pump coupling device has compact structure and small occupation area. The sump pump works because it is submergedThe utility model can be directly installed in a sewage pool, and no special pump house is needed to install a pump and a machine, thereby saving large amounts of land and infrastructure expenses

- Q: Fire pump and shower pump flow head selection, high resolution.

- 2, the volume is greater than 10000 is less than 25000, the minimum water consumption of indoor fire hydrant is 15L/s

- Q: What does the pump mortar do?

- In order to effectively reduce the flow resistance of concrete and pipe, to avoid obstruction caused by pipe sticking and to achieve normal pumping, and its role is generally only pumps.

- Q: What are the functions of a disposable infusion pump?

- This is a very professional question, ha!I only know disposable infusion pumpsAttached: intelligent medical infusion pump and its application

- Q: The difference between submersible pumps and centrifugal pumpsWhat's the difference between the two? What is applicable and what?

- Difference:The installation position is different: one can discharge water, one is on the ground.The work principle is different: the principle of submersible pump is similar to the electric fan, centrifugal pump through centrifugal force to make the water throw out. According to the principle of centrifugal force design,

- Q: How to distinguish the flow and displacement in the hydraulic pump? What's the difference between the two?

- The unit of displacement is the milliliter. How many milliliters does the pump rotate per circle? The displacement is the pump, the individual,The unit of flow is generally a liter, a figure added to the displacement of the pump over a period of time,

- Q: Types and differences of pumps

- Classification and working principle of pump by structureClassification of pumpsInvolved pump standard product types are also very much, a centrifugal pump, metering pump, screw pump, reciprocating pump, hydraulic pump, submersible pump, oil pump, water pump, pressure test pump, vortex pump, cryogenic pump, vacuum pump, roots pump, molecular pump, gear pump, mud pump, corrosion-resistant pump deep well pump, water pump, mixed flow pump, axial flow pump, boiler feedwater pump, liquid pump, injection pump, chemical pump, pump plugging and no leakage pump, plastic pump, fire pump and so on, there are many. Its name is divided according to some conventional classification methods such as pump vane pump volume, pump etc., some are divided by purpose such as sewage pump, pump and other health, some names are more random as diffusion pump, liquid nitrogen pump. As long as the production of this product, with standard requirements, through a certain application and approval procedures may produce a new The standard, but sometimes the content also has a repeated cross, quite. The domestic and foreign standards, the domestic standard is more than the number of foreign standards. In general, such as centrifugal pumps are widely used, the production history of the pump more standard (total standard centrifugal pump up to more than 100). As new standard pump leakage pump this rapid development is relatively small. This paper introduces the structure and working principle of the pump according to the classification of the

- Q: When the water pump is started, why should it start when the outlet valve is closed? Thank you

- The valve opening pump is aimed at the centrifugal pump.From the power curve of the centrifugal pump, the power of the centrifugal pump increases with the increase of the flow rate; the flow curve of the centrifugal pump shows that the flow rate of the centrifugal pump decreases with the increase of the head.

Send your message to us

GBF series fluorine plastic lining pipeline pump

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords