Hot Rolled MS Mild JIS Steel U Channels for Strcutures

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

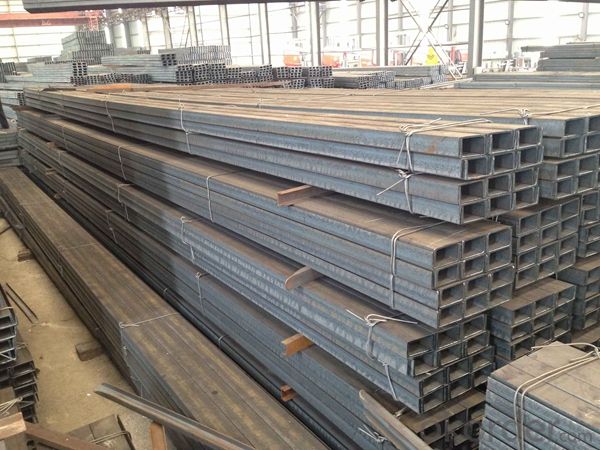

OKorder is offering Hot Rolled MS Mild JIS Steel U Channels for Strcutures at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Hot Rolled MS Mild JIS Steel U Channels for Strcutures are ideal for structural applications and general fabricating. The steel u channel can be applied to construction of warehouses, workshops, sport stadiums and car parks etc. In details, the steel u channel belongs to carbon structural steel which is applied to in the field of construction and machinery. The steel u channel is usually used for arch-itechtural structure, and they could be welded in order to support or hang a vari-ety of facilities. They are also usually used in combination with I beam. Generally,the steel u channel must possess perfect welding property, riveting property and mechanical property and so on.

Product Advantages:

Hot Rolled MS Mild JIS Steel U Channels for Strcutures are durable, strong, and resists corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (7-10 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Steel U Channel Details:

Minimum Order Quantity: 25 Tons Unit: m.t. Loading Port: Xingang Port

Supply Ability: 1000 Tons Per Day Payment Terms: TT or L/C

Product Description:

Specifications of Steel U Channel:

Standard Applied: GB Standard, EN Standard(UPN), JIS Standard

Sizes: 50mm to 300mm

Material Grade: Q235B, Q345B, S235JR, SS400, ASTM A36

As shown in the figure:

| JIS U CHANNEL | Standard h | Sectional b | Dimension s | t | Mass: Kg/m |

| (mm) | (mm) | (mm) | (mm) | ||

| 50x25 | 50 | 25 | 3.0 | 6.00 | 2.37 |

| 75X40 | 75 | 40 | 3.8 | 7.00 | 5.30 |

| 75X40 | 75 | 40 | 4.0 | 7.00 | 5.60 |

| 75X40 | 75 | 40 | 4.5 | 7.00 | 5.85 |

| 75X40 | 75 | 40 | 5.0 | 7.00 | 6.92 |

| 100X50 | 100 | 50 | 3.8 | 6.00 | 7.30 |

| 100X50 | 100 | 50 | 4.2 | 6.00 | 8.03 |

| 100X50 | 100 | 50 | 4.5 | 7.50 | 8.97 |

| 100X50 | 100 | 50 | 5.0 | 7.50 | 9.36 |

| 125X65 | 125 | 65 | 5.2 | 6.80 | 11.66 |

| 125X65 | 125 | 65 | 5.3 | 6.80 | 12.17 |

| 125X65 | 125 | 65 | 5.5 | 8.00 | 12.91 |

| 125X65 | 125 | 65 | 6.0 | 8.00 | 13.40 |

| 150x75 | 150 | 75 | 5.5 | 7.30 | 14.66 |

| 150x75 | 150 | 75 | 5.7 | 10.00 | 16.71 |

| 150x75 | 150 | 75 | 6.0 | 10.00 | 17.90 |

| 150x75 | 150 | 75 | 6.5 | 10.00 | 18.60 |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q4: What makes stainless steel stainless?

A4: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Q5: Can stainless steel rust?

A5: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

Images:

- Q: What are the advantages of using steel channels?

- There are several advantages of using steel channels. Firstly, steel channels offer excellent strength and durability, making them suitable for structural applications that require high load-bearing capacity. Additionally, steel channels have a high resistance to corrosion, ensuring long-lasting performance even in harsh environments. Another advantage is their versatility, as steel channels can be easily fabricated and customized to suit specific project requirements. Moreover, steel channels provide fire resistance, making them a safer choice for construction purposes. Lastly, steel channels have a high recyclability rate, making them an environmentally friendly option.

- Q: 10# how much is it per kilogram of channel steel?

- National standard:Hot rolled plain channel [(GB) 707-65] (unit mm)Height =100, leg width =48, waist thickness =5.3, average leg thickness =8.5, inner arc radius =8.5, leg end arc radius =4.25, sectional area (cm2) =12.74, theoretical weight (kg/m) =10.00

- Q: Are steel channels suitable for use in the construction of platforms or raised floors?

- Yes, steel channels are suitable for use in the construction of platforms or raised floors. Steel channels are commonly used in construction due to their durability, strength, and versatility. They provide excellent support and stability, making them ideal for creating sturdy and reliable platforms or raised floors. Steel channels are known for their ability to withstand heavy loads and resist bending or warping. They can support the weight of machinery, equipment, or people without compromising the structural integrity of the platform or raised floor. This makes them a popular choice in industrial settings, warehouses, factories, and even residential or commercial buildings. Additionally, steel channels are highly resistant to fire, corrosion, and pests, ensuring the long-term durability and safety of the construction. They can be easily customized to fit specific design requirements, allowing for flexibility in creating platforms or raised floors of different sizes and shapes. Furthermore, steel channels can be easily integrated with other construction materials, such as concrete or wood, to provide additional strength and stability. They can also be used in conjunction with other structural components, such as beams or columns, to create a comprehensive and reliable support system. Overall, steel channels offer numerous benefits that make them well-suited for use in the construction of platforms or raised floors. Their strength, durability, versatility, and compatibility with other materials make them a reliable choice for ensuring the stability and safety of such structures.

- Q: What is the maximum length of a steel channel?

- The maximum length of a steel channel depends on various factors such as the manufacturing capabilities, transportation limitations, and the intended application. Generally, steel channels can be produced in lengths ranging from a few feet to several hundred feet. However, the practical limit for transportation and handling purposes is usually around 40 to 60 feet. Beyond this length, special arrangements and equipment may be required to transport and install the steel channel at the desired location. It is important to consult with manufacturers, suppliers, and engineers to determine the maximum length of a steel channel specific to your project requirements.

- Q: Can steel channels be used for supporting exterior cladding systems?

- Yes, steel channels can be used for supporting exterior cladding systems. Steel channels provide structural support and durability, making them suitable for supporting the weight of cladding materials on the exterior of a building.

- Q: What are the different loadings that steel channels can withstand?

- Steel channels can withstand a wide range of loadings, making them a versatile and reliable structural component. The specific loadings that steel channels can withstand depend on various factors, including the type and grade of steel, the size and shape of the channel, and the design of the overall structure. Steel channels are commonly used in construction and engineering applications to provide support and stability. They can withstand both static and dynamic loadings, which include dead loads, live loads, and environmental loads. Dead loads refer to the weight of the structure itself, including the weight of the steel channels and any other components or materials. Steel channels are designed to bear this constant load without deformation or failure. Live loads are temporary loads that can vary in magnitude and location. These loads include the weight of people, furniture, equipment, and other transient forces. Steel channels are designed to support these loads and distribute them effectively to other structural members. Environmental loads include wind loads, snow loads, and seismic loads. Steel channels are designed to resist these external forces and maintain the structural integrity of the building or structure. Wind loads can exert significant pressure on the channels, especially on tall or exposed structures. Snow loads can accumulate and add weight to the structure, which the steel channels must be able to support. Seismic loads refer to the forces generated during an earthquake, and steel channels are designed to withstand these dynamic loads and prevent the structure from collapsing. In addition to these common loadings, steel channels can also withstand other specialized loadings, such as impact loads, vibration loads, and thermal loads. Impact loads can occur due to accidental collisions or sudden impact events and require steel channels to have high strength and toughness. Vibration loads can result from machinery or equipment operation and require steel channels to have good fatigue resistance. Thermal loads can cause expansion and contraction of the steel channels due to temperature changes, and they must be designed accordingly to prevent failure. Overall, steel channels have a high load-bearing capacity and can withstand a wide range of loadings, making them suitable for various structural applications in construction, engineering, and industrial sectors.

- Q: Can steel channels be used in interior design applications?

- Yes, steel channels can be used in interior design applications. Steel channels are versatile and durable, making them suitable for a variety of design purposes. They can be used as structural elements, decorative accents, or even functional features in interior spaces. Steel channels can be creatively incorporated into architectural details such as room dividers, wall paneling, shelving units, and furniture pieces. Their sleek and modern appearance adds an industrial and contemporary touch to any interior design style. Additionally, steel channels can be customized in terms of size, finish, and shape to meet specific design requirements, making them a flexible choice for interior designers.

- Q: Can steel channels be used for overhead garage doors?

- Yes, steel channels can be used for overhead garage doors. Steel channels are commonly used in the construction of overhead garage doors due to their strength, durability, and ability to withstand heavy loads.

- Q: Channel 18, number 18. What does it mean?

- Channel 16#a specifications 160x, 63x, 6.5mm, theoretical weight of 17.24 kg per metre, channel 16#b specifications, 160x 65 8.5mm

- Q: How do steel channels perform under impact loads?

- Steel channels typically perform well under impact loads due to their high strength and rigidity. The structural design and composition of steel channels allow them to absorb and distribute impact forces, minimizing deformation and potential damage. This makes them suitable for applications that require resistance to impact, such as construction, automotive, and infrastructure projects.

Send your message to us

Hot Rolled MS Mild JIS Steel U Channels for Strcutures

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords