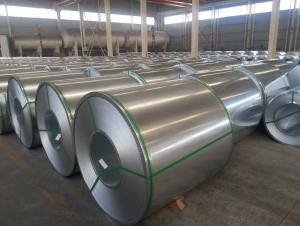

Gavanized steel coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Packaging & Delivery

| Packaging Detail: | Export standard package :bundled wooden box or be required; The inner size of container is below: 20 ft GP:5.8m(length)x 2.13m(width)x 2.18m(high) about 24-26 CBM 40 ft GP:11.8m(length)x 2.13m(width)x 2.72m(high)about 68 CBM We will packing as the factory ,and reach the stander of export . Or as the customer request.In addition,We will make the products with good surface protection. |

| Delivery Detail: | 3-10days after receving the deposite |

Specifications

gavanized steel coil

1) cold rolled steel plate

2) SUCC ,DC01 ,SPCC.

3) Standard GB13237 Q/ ASB 334

- Q: How do steel coils compare to other materials in terms of strength?

- Steel coils are renowned for their remarkable strength and durability, rendering them among the most robust materials obtainable in the market. In comparison to alternative materials like aluminum or plastic, steel coils demonstrate unparalleled strength and resilience against deformation or breakage. Due to the elevated tensile strength of steel, coils can withstand substantial loads, thereby rendering them perfect for diverse industrial uses, encompassing construction, automotive manufacturing, and the production of heavy machinery. Moreover, steel coils possess exceptional fatigue resistance, enabling them to endure repetitive stress and strain without compromising their structural integrity. This strength advantage positions steel coils as the preferred choice for applications that prioritize reliability and safety.

- Q: What are the challenges in the production of steel coils?

- The production process of steel coils encounters several obstacles. Firstly, ensuring consistent quality throughout the process is a major challenge. It is necessary for steel coils to possess uniform thickness, width, and flatness. However, achieving this consistently can prove to be difficult due to variations in raw materials, equipment, and operating conditions. Another hurdle involves effectively managing the intense temperatures involved in the production process. Steel coils are formed by heating steel slabs or billets to extremely high temperatures and subsequently rolling them into coils. Maintaining the necessary temperatures and ensuring proper cooling can be a complex task, as any deviations can result in inconsistencies in the final product. Furthermore, the production of steel coils demands a significant amount of energy. The steel industry ranks among the largest energy consumers worldwide. The constant challenge lies in reducing energy consumption while maintaining production efficiency. To tackle this challenge, the implementation of energy-efficient technologies and process optimization is imperative. Moreover, the production of steel coils generates a substantial amount of waste and emissions. Steel manufacturing involves various chemical reactions that release pollutants such as carbon dioxide, sulfur dioxide, and particulate matter. Meeting environmental regulations and minimizing these emissions are significant challenges for the industry. Additionally, the production of steel coils often involves large quantities, necessitating efficient logistics and transportation systems. Ensuring timely delivery and minimizing damage during transportation can be challenging due to the weight and size of the coils. Lastly, the steel industry confronts market challenges, including fluctuating prices of raw materials, competition from alternative materials, and global economic conditions. Adapting to market demands and maintaining competitiveness are vital for the sustainable production of steel coils. Overall, the challenges in steel coil production encompass maintaining consistent quality, managing high temperatures, reducing energy consumption and emissions, optimizing logistics and transportation, and adapting to market dynamics. Addressing these challenges requires continuous innovation, technological advancements, and a focus on sustainability.

- Q: What are the dimensions of steel coils used in the furniture industry?

- The dimensions of steel coils used in the furniture industry can vary, but common sizes range from 0.5 to 3 millimeters in thickness and 100 to 2000 millimeters in width. The length can be customized based on specific furniture manufacturing requirements.

- Q: What are the dimensions of steel coils used in the building materials industry?

- The dimensions of steel coils used in the building materials industry can vary depending on the specific requirements of the project. However, common dimensions for steel coils in this industry range from 0.15mm to 3.5mm in thickness and 600mm to 2000mm in width. The length of the coils can also vary, typically ranging from 1000mm to 6000mm.

- Q: How does the steel coil market vary regionally?

- The steel coil market varies regionally due to several factors such as the level of industrialization, economic development, and the specific demands and requirements of each region. In developed regions such as North America and Europe, the steel coil market is relatively mature and highly competitive. These regions have well-established manufacturing industries and infrastructure, which create a strong demand for steel coils for various applications such as automotive, construction, and machinery. The market in these regions is driven by factors like technological advancements, product innovation, and the need for high-quality materials. On the other hand, developing regions such as Asia-Pacific, Latin America, and Middle East & Africa experience rapid industrialization and urbanization, driving the demand for steel coils. These regions have growing construction sectors, booming automotive industries, and increasing infrastructure projects, which contribute to the rising demand for steel coils. Additionally, the availability of low-cost labor and raw materials in some of these regions makes them attractive for steel coil production. Furthermore, the regional variations in regulations and trade policies also impact the steel coil market. Tariffs, import/export restrictions, and government initiatives to promote domestic production can affect the market dynamics. For instance, protectionist measures like trade barriers or anti-dumping policies can limit the import of steel coils, leading to increased domestic production and regional market growth. Moreover, geographical factors and climate conditions can also influence regional steel coil markets. Coastal regions with high humidity levels and exposure to saltwater require specialized corrosion-resistant steel coils, while inland regions with extreme temperatures may demand coils with specific mechanical properties to withstand such conditions. Overall, the steel coil market varies regionally due to differences in industrialization, economic factors, specific demands, regulations, and geographical considerations. Understanding these variations is crucial for steel coil manufacturers, suppliers, and consumers to effectively navigate the market and capitalize on the opportunities available in each region.

- Q: Is boron steel or carbon steel a harder metal? Which one is more flexible?

- Boron Steel

- Q: I have the game of the year edition for fallout 3 but there's no mission or quest saying it's called broken steel so what is it actually called and where is it? Please describe the quest in case I mightve already done it without even knowing.

- If I can remember right (SPOILER) you have to beat the game and instead of dying you just pass out and wake up with the brother hood of steel.

- Q: How are steel coils used in the production of steel plates?

- Steel coils are used in the production of steel plates by being fed into a rolling mill where they are gradually flattened and shaped under high pressure. This process, known as hot rolling, transforms the steel coils into thin and flat plates that can be further processed and used in various industries such as construction, automotive, and manufacturing.

- Q: What are the common sizes of steel coils?

- The specific needs and requirements of different industries determine the variations in common sizes of steel coils. However, the steel manufacturing and processing sectors commonly utilize standard sizes. These sizes include: 1. Slit Coils: Typically smaller, slit coils are readily available in widths ranging from 0.5 inches to 72 inches. The weight of slit coils varies, usually falling between 1000 pounds and 50,000 pounds. 2. Master Coils: Larger in size, master coils are generally utilized in steel processing facilities for the production of different steel products. The width of master coils commonly ranges from 36 inches to 96 inches, while the weight may vary from 5,000 pounds to 60,000 pounds. 3. Sheet Coils: Construction, automotive, and appliance manufacturing industries often employ sheet coils. The standard sizes for sheet coils vary, but they are commonly found in widths of 48 inches, 60 inches, and 72 inches, with lengths ranging from 96 inches to 240 inches. 4. Plate Coils: Primarily utilized in heavy-duty applications such as shipbuilding, bridge construction, and pressure vessel manufacturing, plate coils tend to be larger in size. Their widths typically range from 36 inches to 96 inches, while lengths vary from 96 inches to 480 inches. It is important to note that these sizes are not fixed and can be customized according to specific customer requirements. Steel manufacturers and suppliers possess the capability to produce coils in various sizes to cater to the diverse needs of their clients.

- Q: I just got a set of all-clad Stainless steel frying pans, they are very nice yet they didn't come w/ instructions to care for them. I have never cooked w/ stainless steel cookware so I really don't know much about them. I was told they should have a lifetime warranty on them, but I don't want to reck them. I would appreciate any information I can get on stainless steel cookware. Thanks.

- I have stainless steel as well. i clean them like I would with any pan. however once and a while when the bottems get kind of blackened due to spillage or flames I take one of those magic eraser things to clean them up. once every 2-3 months I polish the outsides with a nice stainless steel cleaner.

Send your message to us

Gavanized steel coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords