best selling galvanized steel coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

best selling galvanized steel coil

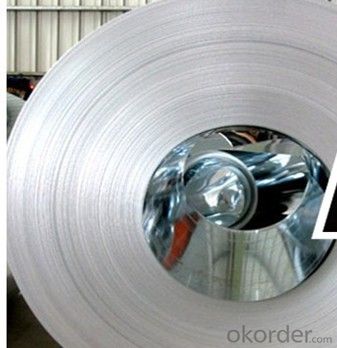

1, Thickness: 0.20mm TCT up to 2mm TCT.

2, Width: 762mm up to 1250mm.

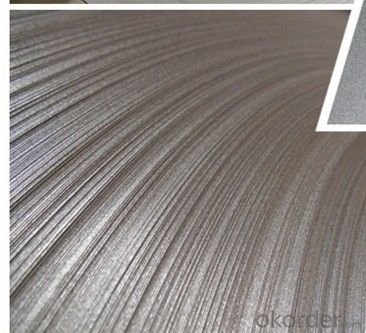

3, Anti-fingerprint Treatment Available.

4, ZINC Caoting: 40-120G/M2.

5, Chromated, Dry, Skin-passed or Non Skin Passed, Tension Level, Shining.

6, Unoiled.

7, Zero Spangle,Mini Spangle ,Regular Spangle, Big Spangle.

8, Temper: No.1, Full Hard (95 HRB; G500-G550).

No.2, Commercial Quality (65 HRB; G300-G350).

9, Coil Weight: 3MT -5MT.

10, Coil ID: 508mm or 610mm.

11, Shipment Method: By Bulk or By Container.

12, Packing: Standard Export Packing.

13, Payment Term: TT or LC at Sight.

14, Delivery: 15-25 Days.

15, Production Lines: Five Lines in all. with an output of 800,000MT Anually

- Q: what happened to all the steel beams from the WTC buildings? did anyone do any forensic analysisof any of the steel?

- Some of the steel was recycled for sale to other countries where they aren't so picky about reusing building materials. NIST had 200 pieces of the steel for their investigation, which they returned last year. This was covered in the press. The rest of the steel was held at JFK international airport's Hangar 17. Much of it will be placed/has been placed in the new museum beneath the Memorial at the WTC site. Thousands of pieces are being given out for 9/11 memorials all over the world. Just about every day you read in the newspaper about another piece going here or there to this city or that city. Yes, a lot of the steel was tested for a number of chemical compounds. It had to be for safety reasons before storing it and giving it out. Depending upon what countries the recycled beams were sent to and their rules, it was sometimes tested at the ports of entry over there, as well.

- Q: Is condensation on steel caused from water being pulled out or is the condensation formed from the air around the steel object?

- Steel contains no water; any water that you see is condensed out of the air.

- Q: What are the different methods of shearing steel coils?

- There exist various approaches to shearing steel coils, each with its own unique pros and cons. Some of the most prevalent methods include: 1. Guillotine Shearing: This technique involves the use of a guillotine-like machine that vertically moves a blade to slice through the steel coil. Guillotine shearing provides high efficiency and accuracy, making it suitable for large-scale industrial production. However, it can lead to deformation or burrs on the cut edges. 2. Rotary Shearing: In rotary shearing, a set of rotating blades is employed to cut through the steel coil. This method enables continuous cutting, making it ideal for high-speed production lines. It ensures a clean and precise cut, but necessitates regular maintenance and blade sharpening. 3. Slitting: Slitting entails passing the steel coil through circular blades that create multiple parallel cuts. This method is commonly used to produce narrower strips from wider coils. It offers great precision and the ability to generate multiple strips simultaneously. However, slitting may result in edge burrs or camber on the strips. 4. Laser Cutting: Laser cutting utilizes a high-powered laser beam to melt or vaporize the steel coil along a predetermined path. This method offers exceptional precision and can cut intricate shapes or patterns. It is commonly employed for specialized applications where accuracy is crucial, although it can be relatively costly. 5. Waterjet Cutting: Waterjet cutting employs a high-pressure stream of water mixed with abrasive particles to cut through the steel coil. This method is versatile and can handle various materials and thicknesses. It is especially useful for cutting heat-sensitive materials or for applications requiring minimal distortion. 6. Plasma Cutting: Plasma cutting involves ionizing a gas to create a plasma arc that melts and blows away the steel coil. This method is fast and efficient, making it suitable for cutting thick steel coils. However, it may produce a wider heat-affected zone compared to other methods. 7. Electrical Discharge Machining (EDM): EDM employs electrical discharges to erode the steel coil and achieve the desired shape. This method is commonly used for intricate or delicate cutting tasks that demand high precision. It is particularly effective for hard materials. Each method of shearing steel coils possesses its own set of advantages and limitations, and the choice depends on factors such as the required precision, speed, material thickness, and the desired end-product.

- Q: Why is steel so important? How does it help us in everyday life?

- steel comes from iron. Iron is a natural resource and is abundent in nature. so being able to turn it into steel means it can be used for alllll sorts of things! from buildings, cars, piping and tubes, to washing machines, appliances and many other things. its used in our everyday life and is a great, strong material.

- Q: How are steel coils classified based on their thickness?

- Steel coils are classified based on their thickness into different gauge categories. These categories range from thin to thick, with each gauge representing a specific measurement.

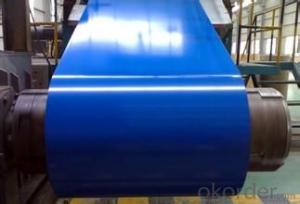

- Q: Can steel coils be coated with epoxy?

- Yes, steel coils can be coated with epoxy. Epoxy coatings are commonly used to protect steel from corrosion and provide a durable finish.

- Q: When I got my AR-15 I was told that I should get either get Brass or Steel Case ammo and stick with one or the other, I was wondering why? It surely wouldn't damage anything switching back and forth between the two would it? I got steel case ammo and I have stuck with It and probably will either way, I was just wanting to know it I ever wanted to get some Hornady's or somthing like that.

- When I first got my ar i used 500rds of wolf steel but since i heard its bad I only use brass but I did shot 30rds of steel then 30rd brass one time at the range and I have not had any problems with it. I have put 700rds though it 500 steel.

- Q: How are defects in steel coils detected and resolved?

- Defects in steel coils are detected through various methods such as visual inspection, ultrasonic testing, magnetic particle inspection, and eddy current testing. Once a defect is identified, it is resolved through processes like grinding, welding, or cutting out the affected area. In some cases, the entire coil may need to be rejected or sent for further processing to eliminate the defect.

- Q: What website can I use to find a good picture that shows the atomic structure of a carbon steel?

- You know, I'd have to say it's very complex.

- Q: How are steel coils used in the production of automotive components?

- Steel coils are used in the production of automotive components through a process called stamping, where the coils are fed into a machine that cuts and shapes the steel into various parts such as body panels, chassis components, and engine parts. These steel components are then assembled to create the final automotive product.

Send your message to us

best selling galvanized steel coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords