Gas Boiler,Circulating Fluidized Bed Boiler,Boimass Fuel Boiler

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Energy efficiency and Environmental protection, Better Quality and Cheaper Price. We would like to provide every kinds of 'Gas Boiler','Circulating Fluidized Bed Boiler','Boimass Fuel Boiler' and looking forward to your kind enquiry.

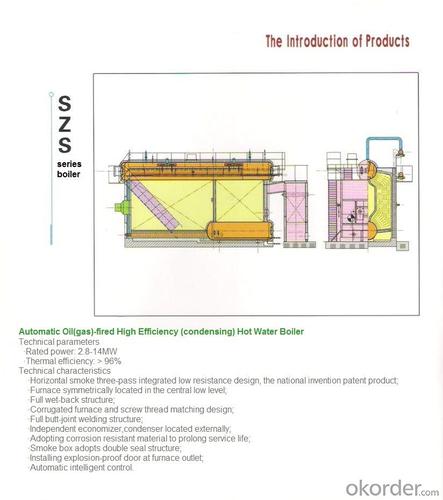

The Gas boiler has double drums, verticalarrangement and “D” type furnace design with 1 or 2 burners located in thefront wall. there is an air-tight furnace structure with densely arranged tubesand air-proof casing inside. and it is covered with insulation materials andconvex color plates outside. The flue gas takes a U turn. It goes into the 1stconvection tube bank from the furnace, turns after passing the flue, and flowsinto the economizer with finned tubes when leaving the 2nd convection tubebank. The water which goes into the upper drum from the economizer is turnedinto steam by means of natural circulation after passing the convection tubebank and water cooled wall, and then supplied to the user via the main steamvalve. Upper and lower drums and convectiontube banks are assembled and subjected to a hydrostatic test prior to delivery.The steam boiler has a capacity of 2~75t/h and working pressure of 0.7~5.4Mpa, while the hot water boilerhas a capacity of 0.7~21MW. The feed water and return water temperatures are 95℃/70℃and 115℃/70℃respectively.

The boiler has the characteristics of smallvolume, compact structure, high combustion efficiency, convenient installation, high degree of automation, etc. Adopting micro positive pressure combustionto improve the thermal efficiency and reduce the operation cost. Upper drumadopts Φ 1000 - Φ 1200 diameter to increase the separation height and guaranteethe quality of steam Boiler flue gas partition wall adopt seal membranestructure not only improve sealing and prevent short circuit but also increase flue gas and improve theutilization ratio of steel and effectively reduce the size of our boiler. holesare pre-opened on membrane wall baffles for timely inspection and repair. Theinspection of convection tube banks is no longer a problem. Convection tubebanks are assembled with special tooling/fixtures, and must pass a hydrostatictest prior to delivery. It not only reduces the installation workload, but alsoensures the boiler quality.

The structure design of densely arrangedtubes and membrane wall with finned tubes ensures that it would never gooverheating outside the furnace tube wall, and the sealing would be maintained.The temperature of insulation and sealing steel plates would not go over 250℃,which ensures the sealing steel plates’ ability of oxidation corrosionresistance.

The design of internal seal casing andexternal embossed casing not only ensures good sealing, but also gives theboiler a better appearance

Our company has various kinds of certificates,such as A-grade Boiler Manufacturing License, A2-grade Pressure VesselManufacturing License, ISO 9001 Quality Control System Certificate, ISO 14001Environmental Management System Certificate and so on . Our company has gaingreat reputation in the Kingdom of Environmental-friendlyBoiler and Pressure Vessel and achieved great success as it has developed morethan 300 kinds of oil/gas-fired environmental-friendly boilers and large amountof non-bidding pressure vessels, which are widely used in every walk of life inthe society. With the excellent performance, high quality and consideration after Sales services, our company gained various kinds of state/province classtechnical advancement awards and led the industry in the technology aspect .Our company has over 5000 customers with the productsspreading everywhere in China and exporting to Southeast Asia, Africa, and Europe.

- Q: We have hot water and heating... no problem. But the boiler keeps making loud clicking/buzzing/hissing noises. Can they explode? Any ideas what's wrong? We can't turn it off for some reason...

- .This could be caused by one of two faults, both easily fixed. 1) check the water pressure gauge on the boiler when the heating is off and cold, if it is above 2 barr there is too much water in the system, remove the front cover and behind the pump there will be a red twist button, twist this to let water out of the system, this should, if the boiler was installed correctly, let the water out through a pipe through the wall. The replace the cover, and top the water back up to no more than 1.5 to 2 barr. turn the boiler on and wait a few seconds for the air to circulate out of the system. 2) The system could have excessive air in it, Bleed the air from the radiators, while keeping an eye on the water pressure gauge, so that it dosn`t fall below the required pressure, starting with the radiator furthest away from the boiler. When all the air is expelled, top up the pressure to 1.5 to 2 barr, and turn the boiler on for a few minutes, to circulate the water. If the noises still persist, call an engineer, as the pump my need servicing.

- Q: after knowing the amount of steam required, how to know the volume of water required to be in boiler and what is the best heating surface (2/3 or more ?)

- what okorder /... In such a case just keep adding tube length to the section which boils the water until you get enough mass of steam boiling- add length to the superheater if you want it hotter.

- Q: I'm considering a deal from my reputable and regular plumber to install a Buderus GB142-24 condensing boiler. This unit is seven months old and had been used in another customers home until that home was enlarged and needed a different size boiler. The plumber says this unit retails for 2900 but will sell it for 2000. I'm assuming this does not include any labor. He is working on a formal bid that I've not yet seen.The rated BTUH input of this unit is about 85,000. I'd like to get a second opinion on the adequacy of this input for my home with two adults and two teens and two bathtubs etc. It will also be used for infloor heat.All of this will be replacing two A O Smith gas Power Shot water heaters, one used for DHW and one for radiant floors. The one used for DHW went kaput today and that is driving this action. Thanks- Dave

- just make sure that your excellent plumber is able to install it for you. Since it's a gently used boiler, you probably are getting a great deal on that particular model (and if it's the only deal you're getting on a boiler, you should probably take it before your partner and teens start having issues with not enough hot water!).

- Q: Could you please recommend any good universities which can offer a degree on this subject. I have a computer engineering degree but over the years, my interest for steam engines has changed to a passion and now, an obsession. I want to learn about designing small steam turbines, its fabrication, material selection, machining methods etc. Can I learn all of this under one degree? Where? Thanks !!( I think it is not possible to learn these stuff online, am I right?)

- Boiler design is usually dealt with in mechanical engineering. You start encountering it in thermodynamics classes but it is not something to be toyed with. You will need a mechanical engineering degree and then multiple years of experience in the working world before attempting your own designs. If you are fabricating your own designs you will also need technical training in machining, usually offered at technical colleges but some mechanical engineers pick it up in the normal course of their working life. Improper design or operation of a boiler can cause catastrophic failure and extreme injuries (death), tread very cautiously!

- Q: How does a boiler room work?

- Well, `boiler room' can mean several different things. Assuming that you just mean a room with a boiler, and want to know how a boiler works, that's easy enough ... In a boiler a liquid is heated and maybe vaporized. Usually the liquid is water. Once heated, the water or steam is used to heat the rest of the building, but it can be used for other things as well. I could go into a lot more detail, but the wikipedia pages below cover the issue pretty well. (And I've included pages for other type of boiler rooms, in case you're asking about one of the other types.)

- Q: Boiler exhaust gas temperature is not the lower the better

- The amount of steam latent heat that can be recovered by the condensing boiler is related to the type of fuel used in the boiler and the effluent temperature of the boiler.

- Q: I found this recipe on food network, but ti calls for me to use a double boiler to create a frosting.. Must i use the double boiler? Or could i just put the ingredients into a stand mixer and whip it? Would it work just as fine? Please let me know asap!

- A okorder /

- Q: I would like to relocate boiler from a bedroom to loft. Is this just a case of extending existing pipework?

- Any time you move a boiler you are affecting HVAC and you need a permit for this. You also have to keep certain clearances from combustible materials and extending the pipes will require an engineer to run calculations to check if you need a larger boiler to handle the extra run. You may also want to check local, state and federal ordinance to see if you are permitted a boiler in the space you want to move it to as some places may have laws prohibiting boilers from being located on certain floors or areas of the home.

- Q: Hi,I currently have 2 boilers, 1 for the radiators and the other for hot water but my boiler for the radiator keeps drawing air into the system, preventing half of the radiators to work and the boiler is roughly 13 years old. So should I keep both boilers and repair the problem or just buy a combi boiler and get the problem sorted at the same time. Thanks for your help in advance

- seems unusual the Worcester guy did not spend somewhat more desirable time on web site and thaw out the condense pipe for you - this is no longer rocket technological awareness - some pictures of warm water from a kettle ought to have executed the pastime with ease how are you going to can blame the installer for the damaging climatic situations ? The person training will say all about checking the condense pipe in chilly climate.

- Q: I had a new natural gas boiler installed just over a year ago. It seems to make a slight rattle/ bang sound when it kicks on! what can I do to remedy the problem

- By all means clean the burners and make sure that the damper is opening in a timely manner. It also could be a sticking flo check or a zone valve, in all reality you should get a good licensed plumber to check it out. There's way to much that could be wrong with the little bit of info your giving.

Send your message to us

Gas Boiler,Circulating Fluidized Bed Boiler,Boimass Fuel Boiler

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords