Galvanized Steel Sheet in Ciols Prime Quality Best Seller

- Loading Port:

- Shanghai

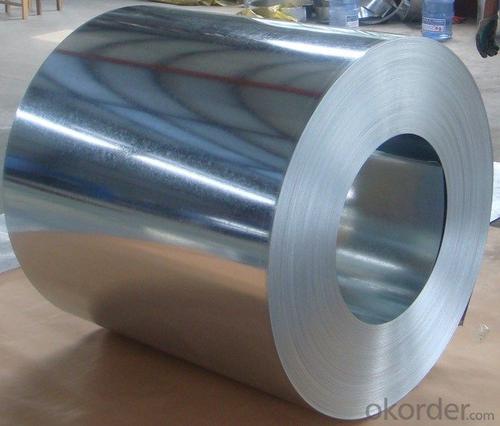

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Galvanized Steel Coil Description:

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc.

Zinc coating :40-180g( as required)

Coil id:508mm/610mm

Coil weight: 4-10 MT(as required)

5.FAQ of Galvanized Steel Coil

We have organized several common questions for our clients,may help you sincerely:

1.How to guarantee the quality of the products?

We have established the international advanced quality management system,

• High corrosion resistance

• High strength

3.Galvanized Steel Coil Images

4.Galvanized Steel Coil Specification

Width:914-1250mm(914mm, 1215mm,1250mm,1000mm the most common)

Grade : SGCD,SGCH, Q195,DX51D

Operate Standard: ASTM A653M-04/JIS G3302/DIN EN10143

2.Main Features of the Galvanized Steel Coil:

• Good formability

• Rust- proof ability

• Good visual effect

- Q: What are the safety precautions when working with steel coils?

- When working with steel coils, it is important to follow several safety precautions. Firstly, workers should wear appropriate personal protective equipment (PPE) such as gloves, safety glasses, and steel-toe boots to protect themselves from potential injuries. Additionally, they should ensure that the work area is well-lit and free from any trip hazards. Proper lifting techniques should be used to prevent strains or sprains, and workers should be trained on how to safely operate any machinery or equipment involved in handling the coils. Regular inspections of the coils, checking for any defects or damages, should also be conducted to avoid accidents. Lastly, workers should be aware of the potential hazards associated with working with steel coils, such as sharp edges, pinching points, and the risk of heavy objects falling, and take necessary precautions to minimize these risks.

- Q: What are the factors driving the growth of the steel coil industry?

- There are several factors driving the growth of the steel coil industry. Firstly, the increasing demand for steel coils in various sectors such as automotive, construction, and manufacturing is a significant driver. Additionally, the expanding infrastructure projects and urbanization in emerging economies contribute to the growth of the industry. Moreover, technological advancements in steel manufacturing processes and the adoption of efficient production techniques also play a crucial role in driving the growth of the steel coil industry.

- Q: I wanted to get a cheapo ring and I found one I like, but it's stainless steel. Is that bad? Will it get dull and tarnished fast?

- Stainless steel will never tarnish so you don't have to worry about it. It's a better choice than silver, for silver,you'll have to clean it with either a cleaner product or toothpaste. Oh yeah, and stainless steel has that cool and modern look.

- Q: How are steel coils processed?

- Steel coils are processed through a series of steps that include uncoiling, levelling, cutting, and recoiling, ensuring the steel is transformed into the desired shape and size for various applications such as construction, automotive, and manufacturing industries.

- Q: How do you prevent damage to steel coils during transportation?

- To prevent damage to steel coils during transportation, several measures can be taken. Firstly, proper packaging and securing techniques should be employed, such as using strong and sturdy crates or pallets to protect the coils from physical impact. Additionally, using protective materials like foam or padding between coils can help cushion them and minimize movement. Secondly, ensuring that the coils are properly loaded and secured in the transport vehicle is crucial. This includes using appropriate restraints, such as straps or chains, to prevent the coils from shifting or falling during transit. Lastly, employing safe driving practices, such as avoiding sudden stops or sharp turns, can also contribute to preventing damage to steel coils during transportation.

- Q: Why do we galvanise steel? Galvanised steel is steel coated with zinc.

- The coating of zinc inhibits rust. First of all the zinc does not oxidize a readily as iron (steel). If the zinc coating gets scratched it still protects the exposed iron. When the zinc and exposed iron get wet they behave like a battery. Electrons flow from the zinc layer to the iron layer. The extra electrons in the iron layer replace any that might be lost to oxidation and help keep the iron metallic. Of course now the zinc oxidizes faster so eventually all of the metallic zinc is removed and the iron is unprotected and will rust. The fact that the zinc doesn't have to cover the steel is shown in another process. To protect the steel hulls of ocean going ships a block of zinc is attached to the bottom. The electrical circuit behaves as described above. When the zinc block has dissolved they just attach another one. If they keep this up the hull of the ship remains corrosion free. A tin coating on steel (as in a tin can) works just the opposite. When the tin is scratched the electrons flow from iron to tin so the iron rusts faster than it would have with no tin.

- Q: What are the common methods of slitting or shearing steel coils?

- The common methods of slitting or shearing steel coils include rotary shear, guillotine shear, and laser cutting.

- Q: Are steel-capped boots safer than non-capped ones when working with horses? I have been told that sometimes if a horse steps on you, the steel crushing into your foot is more dangerous than if you just had normal wellies on, as at least with normal wellies there is some flexibility. Any horsey people out there got any experience with this? Thanks!

- Having had horses tap-dance on my toes while I was wearing normal leather boots, resulting in loss of toenails every now and then, I gotta say that steel-toed boots sound like an awfully good idea.

- Q: Just two sentences on a detailed description on what the steel industry is

- The steel industry is an industry that produces steel. It is one of the largest industries in the world, with China as the leading steel producer

- Q: What are chemical properties of high speed steel? Physical properties?What is high speed steel used for? One interesting fact about high speed steel?

- wikipedia: High speed steel (often abbreviated HSS, sometimes HS) is a material usually used in the manufacture of machine tool bits and other cutters. It is often used in power saw blades and drill bits. It is superior to the older high carbon steel tools used extensively through the 1940s in that it can withstand higher temperatures without losing its temper (hardness). This property allows HSS to cut faster than high carbon steel, hence the name high speed steel. At room temperature, in their generally recommended heat treatment, HSS grades generally display high hardness (above HRC60) and a high abrasion resistance (generally linked to tungsten content often used in HSS) compared to common carbon and tool steels. see reference for more info .

Send your message to us

Galvanized Steel Sheet in Ciols Prime Quality Best Seller

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords