Galvanized Steel Sheet in Ciols Prime Quality Best Seller

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

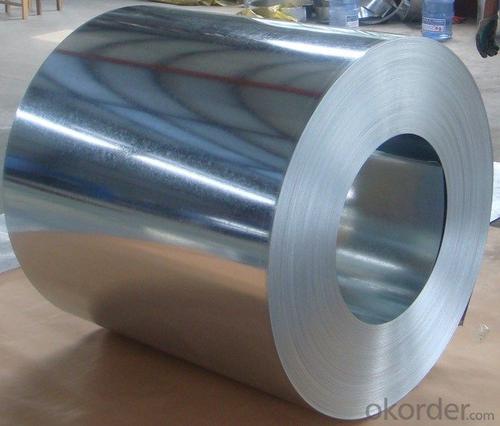

1.Structure of Galvanized Steel Coil Description:

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc.

Coil weight: 4-10 MT(as required)

5.FAQ of Galvanized Steel Coil

We have organized several common questions for our clients,may help you sincerely:

1.How to guarantee the quality of the products?

• High strength

3.Galvanized Steel Coil Images

4.Galvanized Steel Coil Specification

Width:914-1250mm(914mm, 1215mm,1250mm,1000mm the most common)

Grade : SGCD,SGCH,

Operate Standard: ASTM A653M-04/JIS G3302/DIN EN10143

2.Main Features of the Galvanized Steel Coil:

• Good formability

• Rust- proof ability

- Q: What is the AISI grade of mild steel that is the most magnetic? What magnetic steels are the cheapest and easiest to buy?

- That is a part of engineering materials, it has a mixture of materials that has a good magnetic properties when they are combined like silicon and manganese etc.

- Q: Procedures for sharpening a knife with the stone and the steel?

- hi dude, its tough to seek for out intense-high quality steel as a thank you to maintain an side. maximum modern knives are ineffective, It relies upon on what style of side you pick. For the longest sharp side you want to might desire to attain a slowly graded v shape via fashioning the two side with equivalent strokes. The sharpest is a razor or twine side, based if left or appropriate surpassed, get a record and stroke up an down one side in basic terms, to create the burred side then on the choice element your end strokes circulate in direction of the element suited. this might create the sharpest decrease in one direction (left to superb far off from you and a lot of others) Theres some good diamond sprucing stones approximately. decrease than no circumstances use a blade to cut back tomato or distinctive fruit, the acids blunt the blade. Use a serrated side.

- Q: How are galvanized steel coils different from regular steel coils?

- Galvanized steel coils are different from regular steel coils as they are coated with a layer of zinc to prevent corrosion and rust formation. This zinc coating acts as a protective barrier, increasing the longevity and durability of the steel coils, especially in harsh environmental conditions.

- Q: What are the different methods of corrosion protection for steel coils?

- There are several methods of corrosion protection for steel coils, including but not limited to: 1. Coating: Applying a protective layer such as paint, polymer, or zinc coating on the surface of the steel coil to prevent direct contact with corrosive agents. 2. Galvanizing: Immersing the steel coil in a bath of molten zinc, creating a protective coating that prevents corrosion. 3. VCI (Vapor Corrosion Inhibitor): Using volatile corrosion inhibitors that release molecules to form a protective layer on the steel coil, preventing corrosion. 4. Oil or Wax Coating: Applying a layer of oil or wax on the surface of the steel coil to act as a barrier against moisture and corrosive elements. 5. Cathodic Protection: Using sacrificial anodes or impressed current to protect the steel coil by providing a more easily corroded metal that attracts corrosion instead. 6. Desiccants: Placing desiccant materials such as silica gel or molecular sieves inside the packaging to absorb moisture and prevent corrosion. 7. Environmental Control: Maintaining controlled humidity levels, temperature, and proper ventilation in storage areas to minimize the risk of corrosion. 8. Proper Handling and Storage: Implementing safe handling practices during transportation and storing steel coils in dry, covered areas away from corrosive substances. It is important to select the appropriate method based on the specific application, environment, and desired level of protection for the steel coils.

- Q: How are steel coils used in the manufacturing of construction equipment?

- Steel coils are used in the manufacturing of construction equipment as they serve as a primary raw material for the fabrication of various structural components such as frames, bodies, and chassis. These coils are typically processed through cutting, bending, welding, and shaping techniques to create the necessary parts that provide strength, durability, and stability to construction machinery.

- Q: Climbing ropes used by mountaineers are usually made of nylon. Would steel cable of equal strength as the nylon be just as good? What advantages and disadvantages would it have compared to the nylon?

- steel is NOT as flexible and much slipperier if you fall the nylon stretches to slow the victim but a steel cable would stop short and kill you

- Q: How are steel coils used in the production of transportation systems?

- Steel coils are used in the production of transportation systems for various applications such as the manufacturing of automobile parts, railway tracks, and shipping containers. The coils are typically used to create strong and durable components that can withstand the harsh conditions and heavy loads associated with transportation.

- Q: What are the different types of coil recoiling machines?

- The different types of coil recoiling machines include manual coil recoilers, semi-automatic coil recoilers, and fully automatic coil recoilers.

- Q: I want to purchase a set of knives made of carbon steel and want to be able to store them on a magnetic knife strip for handy access, I just wasn't sure if this alloy would stick to a magnet????Thanks

- Yes, carbon steels are magnetic. In fact, some stainless steel knives are magnetic as well. Some stainless steel alloys are naturally magnetic and some become magnetic when they are deformed by forging or rolling (check out a deep drawn SS sink and explore where it is magnetic and where it isn't). Depending on the details, some carbon steels can be made harder than the stainless steel typically used for knives (440 alloy) but the carbon steel knives are very much more likely to suffer corrosion. hope this helps

- Q: How do steel coils perform in high-temperature applications?

- Steel coils perform well in high-temperature applications due to their excellent heat resistance and structural stability. The high melting point of steel allows it to maintain its strength and shape even at elevated temperatures, making it suitable for various industries such as automotive, construction, and manufacturing. Additionally, steel coils can withstand thermal expansion and contraction without warping or deforming, ensuring reliable performance and durability in extreme heat conditions.

Send your message to us

Galvanized Steel Sheet in Ciols Prime Quality Best Seller

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords