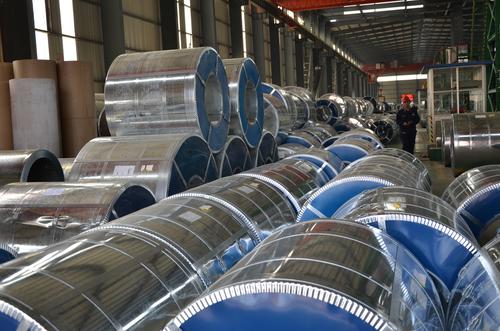

galvanized steel coils

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1) Quality Standard & Grade: JIS G3302, SGCC / ASTM 653M CQ/ EN10142 DX51D+Z

2) Thikness tolerance: +/-0.02mm Width tolerance:+/0.02mm

3) Zinc coating weight: 50g/m2

4) WEIGHT OF PER COIL: 3-5MT

5)Technology: cold rolled

6) Surface of Product: regular spangle / big spangle/ small spangle; Surface Treatment: chromated , non oiled, skin passed

7) Packing: export standard packing,packed with moisture resistant paper and metal

wrapping,securely tied for export,on metal skids7) Country of Origin :

SIZE:0.25*750

- Q: How are steel coils used in the production of steel rings?

- Steel coils are used in the production of steel rings as the primary raw material. The coils are unrolled and cut into smaller sections, which are then shaped and welded together to form the circular shape of the steel rings.

- Q: I am a beginner (never played before!) and I am going to try to teach myself since I think it is a lovely instrument. I am fourteen-years-old so I am not 'adult-size', haha. Anyway, what is difference between nylon strings and steel strings?Thanks :)

- Small guitars easier to find in classical range. I assume their must be small steel strings but not seen them.

- Q: I have a Nike SQ Sumo 21 degree and it is a steel shaft. I hit the ball very high with this club and I lose distance. I don't hit any of my other clubs high it's just this one. Is it because of the steel shaft or is it the club? Help please.

- Actually it isnt so much whether its steel or graphite, although in the past steel was stiffer as a rule. Today many graphite shafts (depending on the shaft manufacturer) are in fact stiffer then some steel shafts. IE proforce XS vs true temper R You also have to look at the kick point in the shaft. The kick point is where the shaft bends at moment of impact. My shafts are tipped lower because I custom made them that way because I typically hit the ball low to begin with. High kick point means lower ball flight and lower means a higher flight. Also different brands have different stiffness' some regular shafts you'll find feel stiffer then other stiff shafts. the only way to tell if its the shaft is to have all the same shafts installed with the same kickpoint hope this helps

- Q: is stainless steel a good steel for sensitive skin? or does it have to be surgical or sterling silver?

- I have sensitvie skin also. I use nickel free and titanium jewlrey, they're the safest. I never used surgical steel before though.

- Q: How hot does steel have to get before it will melt?

- Type your query into Yahoo! Search or other search engines to get the answer: It depends, since steel usually has different metals added for various properties (strength, corrosive resistance, etc.)

- Q: will peircers use surgical steel? how do you know for sure what they are using?

- Most reputable piercers will use surgical steel. You can ask them beforehand and they will let you know what it is they are piercing you with. You can go out and buy a ring of your own and have them sterilize and use that to Peirce you with. Like I said though, most places do use surgical steel. I wouldn't worry too much. :) Just make sure you ask to be sure. Good luck!

- Q: How do steel coils compare to stainless steel coils?

- Steel coils and stainless steel coils find extensive use in various industries due to their robustness and durability. Nevertheless, selecting the appropriate material necessitates considering some essential distinctions between the two. One of the primary disparities lies in the composition of the materials. Steel coils, primarily comprising iron and carbon, incorporate additional elements to enhance specific properties. Conversely, stainless steel coils contain iron, carbon, and a substantial amount of chromium, which imparts them with distinctive corrosion-resistant attributes. Owing to the presence of chromium, stainless steel coils outperform regular steel coils in their resistance to corrosion, tarnishing, and rust. This renders stainless steel coils highly suitable for applications within environments characterized by elevated humidity, moisture, or exposure to corrosive substances. On the contrary, steel coils are more susceptible to rust and may necessitate supplementary protective coatings or treatments to avert corrosion. Another notable differentiation concerns the visual appearance of the two materials. Stainless steel coils boast a lustrous and reflective surface, endowing them with an aesthetically pleasing allure. They commonly find application in contexts where appearance holds significance, such as kitchen appliances, architectural structures, or decorative purposes. Conversely, steel coils exhibit a matte or dull finish and are frequently employed in industrial applications where visual aesthetics are of secondary concern. In terms of strength, both steel and stainless steel coils exhibit excellent mechanical properties. However, stainless steel coils generally demonstrate greater tensile strength and enhanced resistance to high temperatures. Consequently, they prove well-suited for applications necessitating strength, such as the construction, automotive, or aerospace industries. Lastly, cost represents a factor warranting consideration while comparing steel coils to stainless steel coils. Steel coils generally offer a more cost-effective option due to the lower expense of raw materials and simpler manufacturing processes. Nevertheless, when factoring in the added value of corrosion resistance and longevity, stainless steel coils may emerge as a more economical choice in the long run, requiring less maintenance and replacement. To conclude, steel coils and stainless steel coils possess distinct properties and characteristics, rendering them suitable for specific applications. Stainless steel coils exhibit superior corrosion resistance, a glossy appearance, and heightened tensile strength, while steel coils prove more cost-effective. Ultimately, the selection between the two hinges on the precise requirements of the application, encompassing factors such as the environment, aesthetics, strength, and budget.

- Q: How are steel coils used in the production of steel plates?

- Steel coils are used in the production of steel plates by being fed into a rolling mill where they are gradually flattened and shaped under high pressure. This process, known as hot rolling, transforms the steel coils into thin and flat plates that can be further processed and used in various industries such as construction, automotive, and manufacturing.

- Q: How do steel coils contribute to the HVACR industry?

- Steel coils are an essential component in the HVACR industry as they are used in the manufacturing of air conditioning and refrigeration systems. These coils, often made of copper or aluminum, are responsible for transferring heat and facilitating the cooling process. They provide efficient heat exchange, allowing HVACR systems to work effectively and maintain desired temperatures in residential, commercial, and industrial settings.

- Q: Is a steel plate the same as a steel coil?

- Generally speaking, they can be used interchangeably, and the purchase price of the plate is slightly cheaper.

Send your message to us

galvanized steel coils

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords