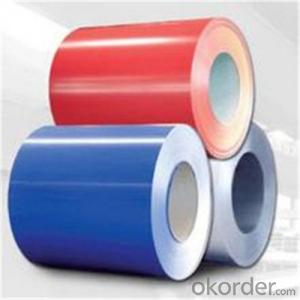

Color coated galvanized rolled steel coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

1.width: 600-1250mm

2.thickness:0.14-1.20mm

3.zinc coating: 60-180g/m2

PPGI with high quality and various color ,suitable for sandwich panel corrugate steel sheet ppgi, color coated galvanized steel coil, ppgi for metal roof

Applications

1. Construction and building: roofing; ventilating duct; handrail; partition panel;etc.

2. Electric appliance: refrigerator; washing machine; refrigerator; DVD;etc.

3.Transportation: oil tank; road sign; etc.

4.Agriculture:barn; etc.

5.Others:vending machine; game machine; etc.

Name | PPGI |

Description | Prepainted Galvanized Steel Coil |

Type | Steel Coil |

Paint Color | Based on RAL No. or customers' color sample |

Paint | Polyester , and your special requirement to be discussed |

Paint Thickness | 1. Top side: 6+11micron 2. Back side:7 micron 3. Or based on customers' requirement |

Steel Grade | Base material SGCC or your requirement |

Thickness Range | 0.14mm-0.8mm |

width | 750-1250mm |

Zinc Coating | 60-140g/m² |

Coil ID | 508mm |

Coil Weight | 3-6MT, or as per customers’ requests |

Technique | Cold Rolled |

Surface Treatment | Galvanized, Chromated, Unoiled/Oiled, Bright Finished, Spangle, Fingerprint Resistance. |

Application | General Use, Roofing, Corrugated Roofing Making, Outside of the buildings |

- Q: What are the different types of steel coil packaging materials used during processing?

- Some of the different types of steel coil packaging materials used during processing include steel strapping, plastic strapping, stretch film, shrink wrap, and coil covers.

- Q: Can you reload spent casings if they are steel?

- Let me break it down for you. 1) There are two kinds of priming in current use these days -- you cannot tell from the outside which primer it is...only by looking inside the casing. If the casing has a single center primer hole, it is Boxer primed. If the casing has multiple primer holes, none of which is center, it is Berdan primed. Berdan and Boxer are the names of men who designed the priming systems.

- Q: How are steel coils inspected for dimensional accuracy after processing?

- Steel coils are inspected for dimensional accuracy after processing using various techniques such as laser scanning, ultrasonic testing, and manual measurements. These methods ensure that the coils meet the required specifications and tolerances, guaranteeing their quality and suitability for further use.

- Q: and which one is better?i'm looking into buying some aftermarket headers, but companies make them in both chrome and stainless steel

- For headers go with stainless steel. Chrome holds heat in, and after a while it will discolor due to the high heat of the heads.

- Q: How are steel coils cut and shaped for specific requirements?

- Steel coils are cut and shaped for specific requirements through a process called slitting and forming. Slitting involves unwinding the coil and passing it through a set of rotary knives that cut it into narrower strips. These strips can be further cut or shaped using tools such as shears, blades, or presses to meet the desired dimensions and specifications. The shaping process may involve bending, rolling, stamping, or welding the strips to achieve the required form. Overall, precision machinery and skilled operators are key in ensuring steel coils are cut and shaped accurately for specific needs.

- Q: How are steel coils used in the manufacturing of electrical wiring?

- Steel coils are used in the manufacturing of electrical wiring to provide strength and support to the wiring. The steel coils are typically used as a core or reinforcement within the wiring to enhance its durability and prevent it from bending or breaking easily.

- Q: What are the different coil packaging machine configurations used for steel coils?

- There are several different coil packaging machine configurations used for steel coils, including horizontal coil packaging machines, vertical coil packaging machines, and orbital coil packaging machines. Horizontal coil packaging machines are typically used for smaller steel coils and provide a horizontal wrapping process. Vertical coil packaging machines are designed for larger steel coils and perform a vertical wrapping process. Orbital coil packaging machines use a rotating ring to wrap steel coils in a circular motion, providing maximum stability and protection. Each configuration offers specific advantages and is chosen based on the size and shape of the steel coils being packaged.

- Q: Can steel coils be rewound?

- Yes, steel coils can be rewound.

- Q: Will hot dip galvanizing affect the properties of the steel

- galvanize a Steel will lose some Small strength bu it will prolong the steel

- Q: How do steel coil manufacturers handle custom orders?

- Steel coil manufacturers handle custom orders by first understanding the specific requirements and preferences of the customer. They then work closely with the customer to determine the desired specifications, including dimensions, thickness, width, coating, and any other specific requirements. The manufacturer uses their expertise and production capabilities to customize the steel coils accordingly. This may involve adjusting the production process, modifying machinery settings, or using different materials. Effective communication and collaboration between the manufacturer and the customer play a crucial role in ensuring the successful fulfillment of custom orders.

Send your message to us

Color coated galvanized rolled steel coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords