Galvanized Iron Window Screening Wire Netting Building Material

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 25000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

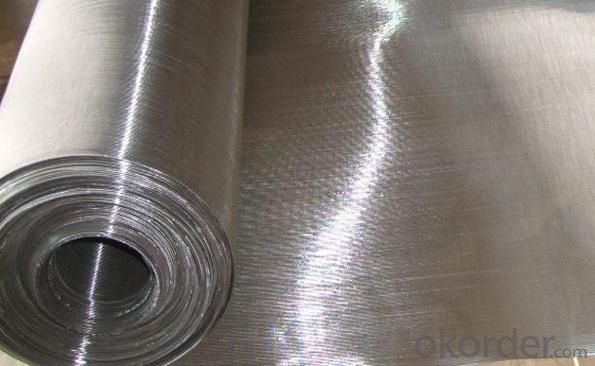

1. Galvanized Iron Window Screening Wire Netting Building Material Description:

Welded wire mesh is also can be called welded wire mesh sheet or welded wire mesh roll according to its making methods. It is one of the most versatile of all wire mesh.

Widely used in industry, agriculture, building, mine, decoration etc.

Materials: high quality low carbon steel wire, stainless steel wire.

Coating style: Electro Galvanized before welding, Electro Galvanized after welding, Hot dipped galvanized before welding, Hot dipped galvanized after welding, PVC coated.

Zinc coating: 20-250g/m2

2.Main Features of Galvanized Iron Window Screening Wire Netting Building Material:

• Versatile, High strength, Easy cutting and shearing, Solid construction, Welding point stronger, Easy handling, corrosion- resisting, oxidation-resisting.

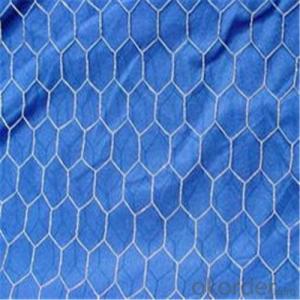

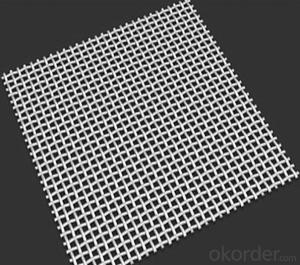

3. Galvanized Iron Window Screening Wire Netting Building Material Images

4.Galvanized Iron Window Screening Wire Netting Building Material Specification

Specification List of Welded Wire Mesh | |||||||||

Opening | Wire Diameter | ||||||||

In inch | In metric unit(mm) | ||||||||

1/4" x 1/4" | 6.4mm x 6.4mm | 22,23,24 | |||||||

3/8" x 3/8" | 10.6mm x 10.6mm | 19,20,21,22 | |||||||

1/2" x 1/2" | 12.7mm x 12.7mm | 16,17,18,19,20,21,22,23 | |||||||

5/8" x 5/8" | 16mm x 16mm | 18,19,20,21, | |||||||

3/4" x 3/4" | 19.1mm x 19.1mm | 16,17,18,19,20,21 | |||||||

1" x 1/2" | 254mm x 12.7mm | 16,17,18,19,20,21 | |||||||

1-1/2" x 1-1/2" | 38mm x 38mm | 14,15,16,17,18,19 | |||||||

1" x 2" | 25.4mm x 50.8mm | 14,15,16 | |||||||

2" x 2" | 50.8mm x 50.8mm | 12,13,14,15,16 | |||||||

Technical Note: | |||||||||

Specification of galvanized hexagonal wire mesh | |||||||||

Specifications | Wire Diameter | Width | |||||||

Mesh(inch) | Size(mm) | Limit Error | BWG | Metric | BS | Metric | |||

3/8” | 10 | +0.5 | BWG27-23 | 0.40-0.6mm | 1”-6” | 0.1-2m | |||

1/2” | 13 | -1.5 | BWG27-22 | 0.4-0.7mm | 1”-6” | 0.1-2m | |||

5/8” | 16 | +1.0/-2.0 | BWG27-22 | 0.4-0.7mm | 1”-6” | 0.1-2m | |||

3/4” | 20 | +1.0/-2.5 | BWG26-20 | 0.46-0.9mm | 1”-6” | 0.1-2m | |||

1” | 25 | +1.5 | BWG25-19 | 0.5-1.0mm | 1”-6” | 0.1-2m | |||

1-1/4” | 31 | -3.0 | BWG24-18 | 0.56-1.2mm | 1”-6” | 0.2-2m | |||

1-1/2” | 40 | +2.0/-4.0 | BWG23-16 | 0.6-1.65mm | 1”-6” | 0.2-2m | |||

2” | 51 | +2.0/-4.0 | BWG22-14 | 0.7-2.0mm | 1”-6” | 0.2-2m | |||

3” | 76 | +2.0/-4.0 | BWG21-14 | 0.8-2.0mm | 1”-6” | 0.3-2m | |||

4” | 100 | +2.0/-4.0 | BWG20-12 | 0.9-2.8mm | 1”-6” | 0.5-2m | |||

Others we can do as your requirement | |||||||||

Specification of PVC coated hexagonal wire mesh | ||

Opening | Wire Diameter | |

Inch | MM | MM |

1/2” | 13mm | 0.6mm-1.0mm |

3/4” | 20mm | 0.8mm-1.1mm |

1” | 25mm | 0.9mm-1.4mm |

1-1/4” | 30mm | 0.9mm-1.5mm |

1-1/2” | 40mm | 0.9mm-1.5mm |

2” | 50mm | 0.9mm-1.5mm |

Others we can do as your requirement | ||

Mesh/inch | Wire Dia. (mm) | Aperture (mm) |

2 | 1.60 | 11.10 |

4 | 1.20 | 5.15 |

5 | 1.00 | 4.08 |

6 | 0.80 | 3.43 |

8 | 0.60 | 2.57 |

10 | 0.55 | 1.99 |

12 | 0.50 | 1.61 |

14 | 0.45 | 1.36 |

16 | 0.40 | 1.19 |

18 | 0.35 | 1.06 |

20 | 0.30 | 0.97 |

30 | 0.25 | 0.59 |

40 | 0.20 | 0.44 |

50 | 0.16 | 0.35 |

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your Galvanized Iron Window Screening Wire Netting Building Material?

One of the most biggest manufacturer & supplier of wires and wire mesh,is a large-scale professional UAE Market Electric Galvanised Wire BWG 20 0.7mm Hot Dipped Galvnised Wire factory in China. Annually more than 10000 tons wires and wire mesh are exported to markets all over the world. Different kinds of wires and mesh are available according to customer’s requirements.

②What is your Technical Information of Galvanized Iron Window Screening Wire Netting Building Material?

1).Material: super carbon steel

2).Processing by drawing, hot-dip zinc-plating

3).Standard wire gauge from 8# to 24#

4).Thick zinc-coating layer

5).Super in corrosion resistance

6).Firm coating layer

7).Custom size available

Galvanized Iron Window Screening Wire Netting Building Material

③How long can we receive the product after payment?

In the purchase of Galvanized Iron Wire within three working days, We will arrange the factory delivery as soon as possible. The pacific time of receiving is related to the state and position of customers. Commonly 15 to 20 working days can be served.

Galvanized Iron Window Screening Wire Netting Building Material

- Q: What is the process of the screen printing process?

- Carton printing, that is, directly in the already made a good corrugated boxes or other cartons, cartons for screen printing; ③ secondary processing, that is, first in the cardboard on the screen printing, and then according to the need to produce corrugated cardboard

- Q: How to get the correct fishing wire

- Screen (sticky net) used in a narrow place, the best night net, pay attention to the depth of water, the Internet is not too heavy too heavy. Can sink on the line.

- Q: The difference between screen printing characteristics

- But also in the ultra-small, ultra-high precision items on the printing, and can also be printed on the surface or spherical, this printing method has great flexibility and wide applicability.

- Q: What is the commonly used mapping software for screen printing?

- screen printing is a stencil printing, it is printed with India, embossing, gravure together known as the four printing methods. The stencil printing includes transcripts, engravings, stencils and screen printing.

- Q: Screen printing and screen printing plate on the photosensitive material What are the requirements

- Synthetic fiber or metal frame pattern using hand-painted film or photochemical plate making silk screen version of the modern silk printing technology is the use of optical materials through the system plate production

- Q: Screen printing ink firmness problem

- If it is PVC tablecloth, you can try to corona the first surface of the printing process, so that the surface tension higher (recommended to 55 - 60 dyne), and then see if there is improvement.

- Q: How to make screen printing layout smooth

- Paint the (pattern) paint, repeat it several times and check that the pattern is transparent. If the number of prints is not large, the back generally do not need to paint.

- Q: What is the screen printing plate?

- wire mesh Stretched into the box after the screen called, was translucent, flexibility and toughness is very strong.

- Q: Screen printing and printing the difference

- Full name screen printing is a stencil printing, it is printed with flat, embossed, gravure together known as the four printing methods.

- Q: What are the characteristics of screen printing?

- Screen printing generally has the following characteristics: not subject to printing the size and shape of the restrictions, the layout of the soft pressure small

Send your message to us

Galvanized Iron Window Screening Wire Netting Building Material

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 25000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords