Hexagonal Wire Netting Galvanized /PVC Coated for Building Materials

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 kg

- Supply Capability:

- 3000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Hexagonal Wire Netting Description:

Hexagonal Wire Netting with its good corrosion resistance and oxidation resistance, serves well in strengthening protection and temperature keeping materials in the form of mesh container, stone cage, isolation wall, boiler cover or poultry fence in construction, chemical, breeding, garden and food processing industries.

Hexagonal wire mesh is also called chicken wire, poultry netting ,rabbit netting. It is common used to fence chicken, poultry, rabbit and other animals.The hexagonal wire mesh is made of black iron wire, galvanized iron wire, brass wire or stainless steel wire with hexagonal gaps, available in3/8 inch to 4inch ( 10mm to 100mm),wire gauge from BWG14 to BWG27 (2.1mm to 0.4mm).

2.Main Features of Hexagonal Wire Netting:

• Nice Shape

• Use widely

• Solid

• Simple weaving

• Good anti-corrosion

• Practical use

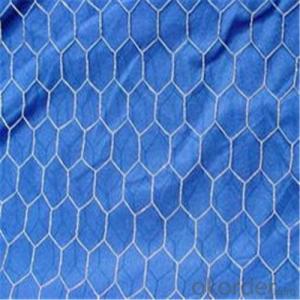

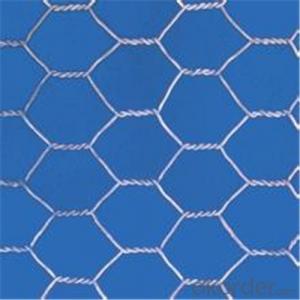

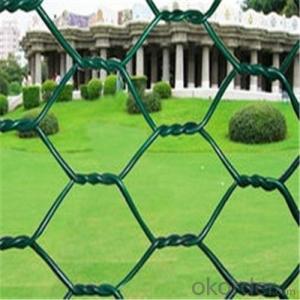

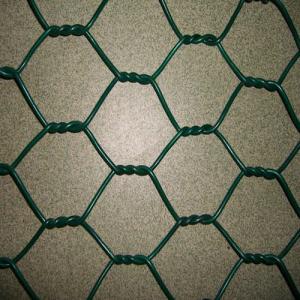

3. Hexagonal Wire Netting Images

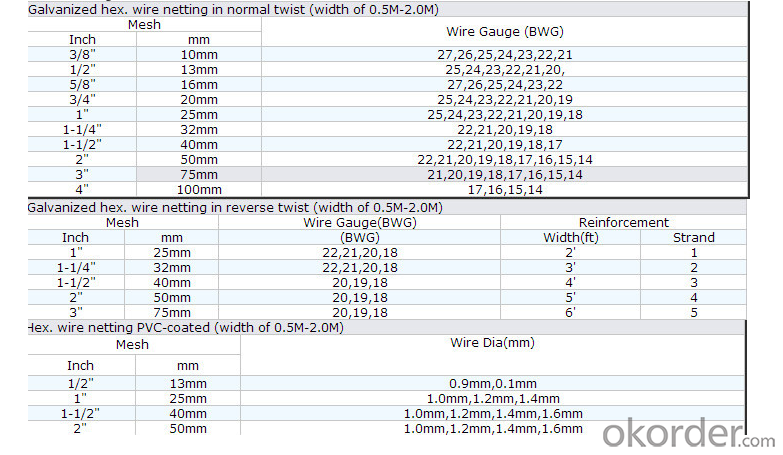

4. Hexagonal Wire Netting Specification

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your Hexagonal Wire Netting?

We have 20 years' experience for export/produce Hexagonal Wire Netting. About 100 persons works in this line, 10 production lines can produce about 200 sets every day. We have our own quality inspection departments to strictly according to customer requirements to complete production. Which have exported to lots of countries before such as: Australia, Italy, Mexico, Gaborone, Kenya..... And so on. We have a professional management team and many skilled workers Owns 20 production lines, we have a strong production capacity We can provide high-quality products.

②What is the Hexagonal Wire Netting Accessories:

* Hex. wire mesh in normal twist

* Hex. wire mesh in reverse twist

* Hex. wire mesh in bidirectional twists

* Electro Galvanized before Weaving

* Electro Galvanized After Weaving

* Hot Dipped Galvanized before Weaving

* Hot Dipped Galvanized after Weaving

* PVC Coated Before or After Weaving

③How long can we receive the product after purchase?

In the purchase of Hexagonal Wire Netting within three working days, we will arrange the factory delivery as soon as possible. The pacific time of receiving is related to the state and position of customers. Commonly 15 to 20 working days can be served.

- Q: What is the effect of the wire mesh on the floor

- to speed up the heat: because the thermal conductivity of iron is relatively strong so that the ground is very uniform heat.

- Q: How the wire is welded

- Will not affect the strength of the wire. It is not easy to break due to excessive heat input. Fusion welding can not do this.

- Q: Barbed wire mesh 20 mesh and 30 mesh what is the difference

- The number of points refers to the length of an inch within the number of cells, then the 20-finger is an inch length of 20 cells, 30 mesh is an inch length of 30 cells, the same length of this contrast is that

- Q: Wall tiles how to hang iron wire mesh

- Coating is thin, usually within 5-30 microns, so the anti-corrosion time will be relatively short. Cold galvanized wire mesh features: mesh formation, mesh uniform, solid solder joints, local processing performance, bright colors, beautiful. Cold galvanized wire mesh Uses: Widely used in industrial and agricultural construction fence.

- Q: Wire mesh for wire mesh applications

- In the era of peace, barbed wire is not only widely used in machinery, electronics, pharmaceutical, petrochemical, glass, food drying, plastics, paper and chemical fiber, picture tube and other industries, and barbed wire is also widely used in agriculture and life in all aspects.

- Q: Construction in the wall and the beam at the junction of nail wire mesh what role

- To avoid the ground cracks, wire mesh must be placed on the pipe above the concrete center is better.

- Q: How does proe draw wire mesh?

- With a way to scan it to a roughness (wire diameter), because the barbed wire is two cross, so the mirror in the center of a mirror out of the two wire will be created into a group, (selected - right - group )

- Q: What is the barbed wire in the cable line?

- If there is no such network, the TV signal is highly susceptible to some of the frequency of interference, resulting in increased noise on the screen, and even lead to poor synchronization.

- Q: What is the barbed wire fence? What is the general specification?

- It is drawn from the wire rod into a thin wire (cold wire), and then through a large welding machine will wire welding (that is, we commonly known as wire mesh).

- Q: Why do you want to shop a barbed wire?

- Barbed wire to determine a good fixed later, you can start plastering, of course, this step is also a measure of the degree of intentions of tileworkers, plaster live to do more detailed, the more flat the wall, the latter part of the possibility of the problem will be relatively small some.

Send your message to us

Hexagonal Wire Netting Galvanized /PVC Coated for Building Materials

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 kg

- Supply Capability:

- 3000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords