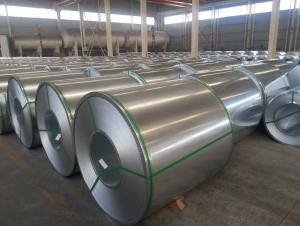

Galvalume Steel Coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

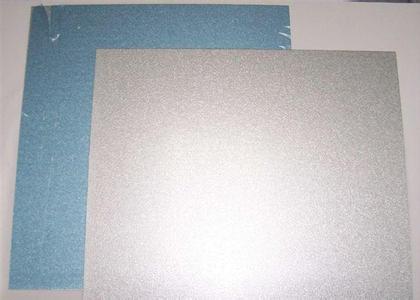

Aluzinc coils.

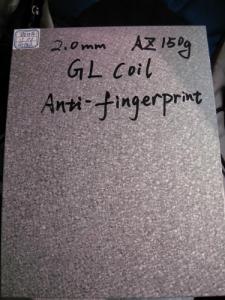

AZ150 with Anti-Finger Print. AZ150, +/-10g/㎡

0.5 x 1200mm

Coil ID: 508mm.

VALIDITY: 3 WORKING DAYS

PAYMENT: 100% LC AT SIGHT

SHIPMENT: 60 DAYS AFTER LC ISSUING DATE

- Q: What are the different methods of punching steel coils?

- There are several different methods used for punching steel coils, depending on the specific requirements and desired outcome. Here are a few common methods: 1. Mechanical Punching: This method involves using a mechanical press to apply force and create holes in the steel coil. It utilizes a punch and die set, where the punch is driven into the coil to create the hole. Mechanical punching is ideal for punching small to medium-sized holes and is often used in high-volume production settings. 2. Hydraulic Punching: Hydraulic punching utilizes hydraulic pressure to drive the punch into the steel coil. This method is often used for punching larger holes or shapes that require greater force. Hydraulic punching machines offer precise control and can handle thicker and harder materials. 3. Laser Cutting: Laser cutting is a non-contact method that uses a laser beam to cut through the steel coil. A focused laser beam is directed onto the coil, melting and evaporating the material to create the desired shape or hole. Laser cutting offers high precision and can be used for complex shapes and patterns. 4. Plasma Cutting: Plasma cutting involves using a high-velocity jet of ionized gas (plasma) to melt and remove the steel coil material. This method is suitable for cutting thicker steel coils and is often used for larger holes or irregular shapes. 5. Waterjet Cutting: Waterjet cutting utilizes a high-pressure jet of water mixed with abrasive particles to cut through the steel coil. This method is versatile and can effectively cut through various materials, including steel. Waterjet cutting is known for its high precision and clean cuts. Each method of punching steel coils has its own advantages and considerations. Factors such as material thickness, desired precision, production volume, and cost will determine the most suitable method for a specific application.

- Q: What is the shear modulus of steel and silver? Please help! and state where you got it from...what site did you used? Thanks.

- Modulus Of Rigidity Of Steel

- Q: hello friends, I have some old 7.62x54r on stripper clips its nasty gunk on it can i use steel wool to glean it and still have it fire safely?

- You could, but if you have access to a vibrating case tumbler, it would work much better. I just tumbled a batch of 1,000 of tarnished and dirty Romanian 7.62X25 and it now looks like brand new commercial ammo.

- Q: What is the purpose of steel coils?

- The purpose of steel coils is to efficiently store and transport large quantities of steel in a compact and organized manner.

- Q: How do steel coils compare to other types of metal coils?

- Steel coils are generally considered superior to other types of metal coils due to their exceptional strength, durability, and versatility. Steel coils have excellent resistance to corrosion, heat, and impact, making them suitable for various applications ranging from construction and automotive industries to manufacturing and packaging sectors. Additionally, steel coils exhibit excellent formability and can be easily shaped and molded into different shapes and sizes, offering greater flexibility and customization options.

- Q: What is the minimum temperature that steel coils can withstand?

- The minimum temperature that steel coils can withstand depends on the specific grade of steel and its intended application. However, in general, most steel coils can withstand temperatures as low as -40°C (-40°F) without significant damage or structural failure.

- Q: I was wondering what kind of company casts and sells steel without acting as a contractor as well. They only sell steel no install it

- If you are talking about raw steel materials and products I believe you are talking about a steel processor and warehouse company or a steel distributor. There are many different points along the steel manufacturing process that you could buy steel products. It would depend on various factors. Depending the amount, type, grade, gauge, properties, origin and a host of other elements you could purchase the steel in billet, plate, diamond plate, rolled sheet (cold or hot), coil, beam, stamped, pickled, scrapped, etc. You get the idea. Now I don't know where you are in the world, but you can go to one of the two sites below, which I have used for product sourcing and research before. The last one is a major manufacturer that I have actually been to. I hope this helps.

- Q: I bought a stainless steel mood ring two days ago, but would it rust?Thanks in advance!

- Stainless steel can rust if placed in contact with some chemicals lik hypoclorite, bleach, or salt water. It depends on the type of stainless steel because there is not just a single stainless steel but a family of steel with different properties and corrosion resistance.

- Q: What is the role of steel coils in the production of conveyors?

- Steel coils are used in the production of conveyors as they serve as the main structural component for supporting and guiding the conveyor belt. These coils are typically formed into a cylindrical shape and act as a sturdy foundation for the belt to rest on. Additionally, the strength and durability of steel coils ensure that the conveyor can withstand heavy loads and constant movement, making them essential for efficient and reliable conveyor systems.

- Q: How are steel coils used in the production of metal doors and windows?

- Steel coils are an essential component in the production of metal doors and windows. These coils are typically made from high-quality steel and serve as the primary raw material for manufacturing these products. The first step in utilizing steel coils is the process of uncoiling. The coils are unwound and fed into a machine known as a roll former. This machine carefully shapes the steel into the desired profile for the door or window frame. The steel is typically cut to the required length before being fed into the roll former. Once the steel has been shaped, it is then sent through a series of additional manufacturing processes. These processes may include punching holes for hardware installation, bending the steel to create specific angles or curves, and welding different sections together to form a complete frame. The steel coils provide the necessary structural integrity and durability required for these processes. Furthermore, steel coils also play a crucial role in enhancing the aesthetic appeal of metal doors and windows. They can be coated with various finishes, such as galvanized or powder-coated, to provide protection against corrosion and improve the overall appearance of the final product. These coatings not only add a layer of durability but also allow for customization to match different architectural styles and design preferences. In summary, steel coils are the foundational material used in the production of metal doors and windows. They are shaped, cut, and processed to create the necessary components for these products. Additionally, steel coils can be coated to enhance their durability and aesthetic appeal. Ultimately, these coils contribute significantly to the strength, durability, and overall quality of metal doors and windows.

Send your message to us

Galvalume Steel Coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords