Gallium Arsenide Solar Cells Price - Poly 156x156mm2 Grade A Solar Cells

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4999 watt

- Supply Capability:

- 6000000 watt/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The operation of a photovoltaic (PV) cell requires 3 basic attributes:

The absorption of light, generating either electron-hole pairs or excitons.

The separation of charge carriers of opposite types.

The separate extraction of those carriers to an external circuit.

In contrast, a solar thermal collector supplies heat by absorbing sunlight, for the purpose of either direct heating or indirect electrical power generation from heat. A "photoelectrolytic cell" (photoelectrochemical cell), on the other hand, refers either to a type of photovoltaic cell (like that developed by Edmond Becquerel and modern dye-sensitized solar cells), or to a device that splits water directly into hydrogen and oxygen using only solar illumination.Characteristic of Mono 156X156MM2 Solar Cells

You are gaining energy independence - add battery backup power for even greater energy security

The cost of electricity is only going to rise – insure against that rising cost

Adaptive cells change their absorption/reflection characteristics depending to respond to environmental conditions. An adaptive material responds to the intensity and angle of incident light. At the part of the cell where the light is most intense, the cell surface changes from reflective to adaptive, allowing the light to penetrate the cell. The other parts of the cell remain reflective increasing the retention of the absorbed light within the cell.[67]

In 2014 a system that combined an adaptive surface with a glass substrate that redirect the absorbed to a light absorber on the edges of the sheet. The system also included an array of fixed lenses/mirrors to concentrate light onto the adaptive surface. As the day continues, the concentrated light moves along the surface of the cell. That surface switches from reflective to adaptive when the light is most concentrated and back to reflective after the light moves along

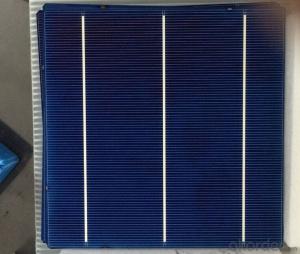

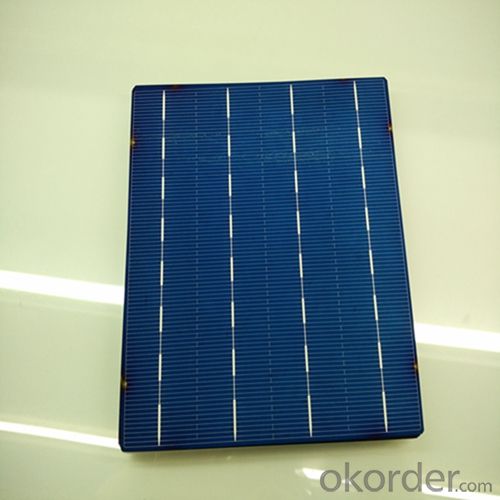

Mechanical data and design

Format | 156mm x 156mm±0.5mm |

Thickness | 210μm±40μm |

Front(-) | 1.5mm bus bar (silver),blue anti-reflection coating (silicon nitride) |

Back (+) | 2.5mm wide soldering pads (sliver) back surface field (aluminium) |

Temperature Coefficient of Cells

Voc. Temp.coef.%/K | -0.35% |

Isc. Temp.coef .%/K | +0.024%/K |

Pm.Temp.coef. %/K | -0.47%/K |

Electrical Characteristic

Effiency(%) | Pmpp(W) | Umpp(V) | Impp(A) | Uoc(V) | Isc(A) | FF(%) |

18.35 | 4.384 | 0.526 | 8.333 | 0.63 | 8.877 | 78.39% |

18.20 | 4.349 | 0.526 | 8.263 | 0.63 | 8.789 | 78.54% |

18.05 | 4.313 | 0.525 | 8.216 | 0.63 | 8.741 | 78.32% |

17.90 | 4.277 | 0.524 | 8.161 | 0.625 | 8.713 | 78.04% |

17.75 | 4.241 | 0.523 | 8.116 | 0.625 | 8.678 | 77.70% |

17.60 | 4.206 | 0.521 | 8.073 | 0.625 | 8.657 | 77.36% |

17.45 | 4.170 | 0.519 | 8.039 | 0.625 | 8.633 | 76.92% |

17.30 | 4.134 | 0.517 | 8.004 | 0.625 | 8.622 | 76.59% |

17.15 | 4.096 | 0.516 | 7.938 | 0.625 | 8.537 | 76.80% |

17.00 | 4.062 | 0.512 | 7.933 | 0.625 | 8.531 | 76.18% |

16.75 | 4.002 | 0.511 | 7.828 | 0.625 | 8.499 | 75.34% |

16.50 | 3.940 | 0.510 | 7.731 | 0.625 | 8.484 | 74.36% |

FAQ

FAQ

Q: What price for each watt?

A: It depends on the quantity, delivery date and payment terms, generally Large Quantity and Low Price

Q: What is your size for each module? Can you tell me the Parameter of your module?

A: We have different series of panels in different output, both c-Si and a-Si. Please take the specification sheet for your reference.

Q: What is your size for each module? Can you tell me the Parameter of your module?

A: We have different series of panels in different output, both c-Si and a-Si. Please take the specification sheet for your reference.

- Q: Can solar cells be used for powering electric vehicles charging stations?

- Yes, solar cells can be used to power electric vehicle charging stations. Solar panels can convert sunlight into electricity, which can then be used to charge electric vehicles. This helps to utilize renewable energy sources and reduce the carbon footprint associated with charging electric vehicles.

- Q: How much space is required to install a solar cell system?

- The space required to install a solar cell system depends on various factors such as the capacity of the system, the type of solar panels used, and the available sunlight. Generally, a small residential solar system can be installed on a rooftop or an area of about 100-200 square feet, while larger commercial or utility-scale systems can require several acres of land.

- Q: Can solar cells be used in boats or marine applications?

- Yes, solar cells can definitely be used in boats or marine applications. They provide a sustainable and renewable source of energy to power various systems onboard, such as navigation equipment, lighting, battery charging, and even propulsion systems. Solar panels can be installed on the deck or roof of a boat, where they can harness the sun's energy to generate electricity and reduce reliance on fossil fuels.

- Q: Can solar cells be used in smart home automation systems?

- Yes, solar cells can be used in smart home automation systems. Solar cells can generate electricity from sunlight and can be integrated into the smart home system to power various devices and sensors. This allows for energy-efficient and sustainable operation of the automation system, reducing reliance on conventional power sources and lowering electricity costs.

- Q: What is the impact of saltwater exposure on solar cell efficiency?

- Saltwater exposure can have a significant negative impact on solar cell efficiency. The saltwater can corrode the metal components of the solar cells, leading to a decrease in their performance and overall efficiency. Additionally, the saltwater can create a conductive pathway that can bypass the solar cells, resulting in a loss of electrical energy. Therefore, it is crucial to protect solar cells from saltwater exposure to maintain their efficiency and prolong their lifespan.

- Q: How do solar cells perform in high pollution areas?

- Solar cells may be less efficient in high pollution areas due to the reduced amount of sunlight reaching the cells. The presence of pollutants in the air can block or scatter sunlight, decreasing the amount of light that solar cells can convert into electricity. Additionally, pollutants can accumulate on the surface of the cells, further reducing their performance. However, advancements in solar cell technology and regular cleaning can help mitigate the negative effects of pollution, allowing solar cells to still generate electricity, albeit at a slightly lower efficiency.

- Q: Can solar cells be used in grid-tied systems?

- Yes, solar cells can be used in grid-tied systems. In a grid-tied system, solar cells generate electricity from sunlight and feed it directly into the electrical grid. This allows homeowners or businesses to offset their energy consumption and even earn credits for excess electricity produced, making it an efficient and sustainable option for renewable energy integration.

- Q: How are solar cells manufactured?

- Solar cells are manufactured through a process that involves several steps. First, raw materials such as silicon, which is the main component of solar cells, are purified and shaped into cylindrical ingots. These ingots are then sliced into thin wafers. Next, the wafers are treated with various chemicals to create a p-n junction, which is essential for the conversion of sunlight into electricity. This involves applying a layer of phosphorus to one side of the wafer, which creates the n-type layer, and a layer of boron to the other side, creating the p-type layer. Afterwards, the wafers are coated with an anti-reflective material to increase their efficiency in capturing sunlight. Metal contacts are then added to both sides of the wafer to collect the generated electricity. Finally, the wafers are assembled into modules or panels, where they are protected with a glass cover and encapsulated with a weather-resistant backsheet. These modules are then tested for quality assurance before they are ready for installation and use in solar energy systems.

- Q: What is the average cost of a solar cell?

- The average cost of a solar cell varies depending on factors such as the type of cell, its efficiency, and the size of the installation. However, as of 2021, the average cost is approximately $0.30 to $0.40 per watt for residential installations and $0.20 to $0.30 per watt for utility-scale installations. It's important to note that these costs have been decreasing over the years due to advancements in technology and increased adoption of solar energy.

- Q: How much land is required to install solar cells?

- The amount of land required to install solar cells depends on various factors such as the capacity of the solar system, efficiency of the solar panels, and the power generation goals. On average, it is estimated that a 1 MW solar power plant requires about 4-5 acres of land. However, with advancements in solar technology, the land requirements are decreasing as solar panels become more efficient and produce more power per square foot.

Send your message to us

Gallium Arsenide Solar Cells Price - Poly 156x156mm2 Grade A Solar Cells

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4999 watt

- Supply Capability:

- 6000000 watt/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords