Triple Junction Gallium Arsenide Solar Cells - Polycrystalline A Grade 3BB 156*156mm Low Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 8000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

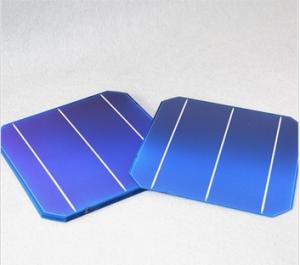

Polycrystalline Silicon Solar Cells:

Solar cells is made by solar wafer, it has three categories of solar cell right now, monocrystalline polycrystalline and thin film,These cells are entirely based around the concept of ap-n junction, which is the critical part of solar module, it is the part that can convert the light energy into electricity, the thickness is from 180um to 200um, with even busbars to conduct electricity, textured cell can decrease diffuse reflection; they are often electrically connected and encapsulated as a module. Photovoltaic modules often have a sheet of glass on the front (sun up) side, allowing light to pass while protecting semiconductor wafers from abrasion and impact due to wind-driven debris, rain, hail, etc. Solar cells are also usually connected in series in modules, creating an additive voltage. Connecting cells in parallel will yield a higher current;With high quality and stable quality. Our Cells can greatly improve the performance of Solar Modules.

Polycrystalline Silicon Solar Cells Advantage:

• High efficiency and stable performance in photovoltaic conversion.

• Advanced diffusion technique ensuring the homogeneity of energy conversion efficiency of the cell.

• Advanced PECVD film forming, providing a dark blue silicon nitride anti-reflection film of homogenous color and attractive appearance.

• High quality metal paste for back surface and electrode, ensuring good conductivity, high pulling strength and ease of soldering.

• High precision patterning using screen printing, ensuring accurate busbar location for ease with automatic soldering a laser cutting.

Physical characteristics

Dimension: 156*156mm±0.5mm

Thickness: wafer(si): 200μm±20μm

Cell: 240μm±40μm

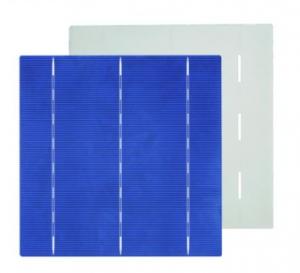

Front: silver bus bars;dark blue/others silicon nitride anti reflection coating

Back: silver/aluminum bus bars;full-surface aluminum BSF

Specification:

Mechanical data and design |

Format - 156 mm × 156 mm ± 0.5 mm |

Thickness- - 200 μm ± 20 μm |

Front (-) - 1.4 mm bus bars (silver),blue anti-reflection coating (silicon nitride) |

Back (+) - 2 mm wide soldering pads (silver) back surface field (aluminium) |

Temperature Coefficient of Cells |

Voc. Temp .coef.%/K -0.364%/K |

Isc . Temp .coef.%/K +0.077%/K |

Pm. Temp. coef.%/K -0.368%/K |

Efficiency code | Efficiency(%) | Pmax(w) | Impp(A) | Vmpp(V) | Isc(A) | Voc(V) |

182 | ≥18.20 | 4.43 | 8.26 | 0.536 | 8.71 | 0.634 |

180 | 18.0-18.2 | 4.38 | 8.22 | 0.533 | 8.68 | 0.632 |

178 | 17.8-18.0 | 4.33 | 8.17 | 0.530 | 8.63 | 0.630 |

176 | 17.6-17.8 | 4.28 | 8.12 | 0.527 | 8.60 | 0.627 |

174 | 17.4-17.6 | 4.23 | 8.08 | 0.524 | 8.56 | 0.625 |

172 | 17.2-17.4 | 4.19 | 8.05 | 0.521 | 8.53 | 0.622 |

170 | 17.0-17.2 | 4.14 | 7.99 | 0.518 | 8.49 | 0.620 |

168 | 16.8-17.0 | 4.09 | 7.94 | 0.515 | 8.45 | 0.618 |

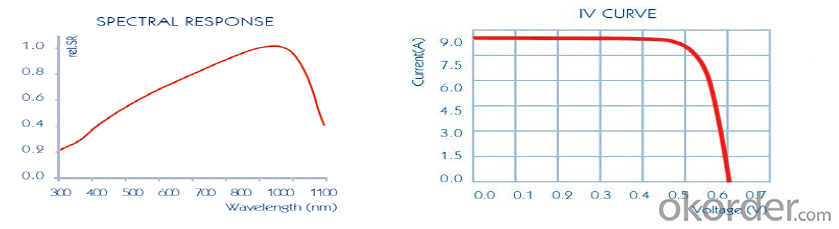

Intensity Dependence |

Intensity [W/m2] Isc× [mA] Voc× [mV] Pmpp |

1000 1.00 1.000 1.00 |

900 0.90 1.000 0.90 |

800 0.80 0.99 0.80 |

500 0.50 0.96 0.49 |

300 0.30 0.93 0.29 |

200 0.20 0.92 0.19 |

IV Curve

Solar Panel Images:

Packaging & Delivery of Polycrystalline Solar Cells

Carton Box Package and Deliver by air. It should be noticed that it should be avoid of water, sunshine and moist.

FAQ

We have organized several common questions for our clients,may help you sincerely:

①What price for each watt?

It depends on the efficiency of the solar cell, quantity, delivery date and payment terms.

②How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

③Can you provide the peripheral products of the solar panels, such as the battery, controller, and inverter? If so, can you tell me how do they match each other?

Yes, we can, we have two companies for solar region, one is CNBM International, the other is CNBM engineering Co.

We can provide you not only the solar module but also the off grid solar system, we can also provide you service with on grid plant.

④What is your warranty of solar cell?

Our product can promise lower than 0.3% open box crack, we support claim after opening the box if it has crackm color difference or sth, the buyer should give pictures immediately, we can not accept the claim after the solar cell has assembled to solar panel.

• Timeliness of delivery

• ⑤How do you pack your products?

We have rich experience on how to pack the solar cell to make sure the safety on shipment, we could use wooden box or pallet as buyer's preference.

⑥ Can you do OEM for us?

Yes, we can.

Solar power has been able respected, more and more widely used, in large part because it is environmentally friendly way of generating renewable power generation process does not produce carbon dioxide and other greenhouse gases, will not pollute the environment, and therefore widely. From the current terms of the types of solar cells, including crystalline silicon cells, thin film batteries and other battery materials. Monocrystalline silicon cells are divided into cells, polycrystalline cells and amorphous silicon thin-film batteries.

For solar cells, the most important parameter is the photoelectric conversion efficiency, developed in the laboratory of silicon-based solar cells, Monocrystalline silicon cell efficiency of 25.0%, polycrystalline silicon cell efficiency of 20.4%, CIGS thin-film cell efficiency of 19.6%, CdTe thin film cell efficiency of 16.7%, an amorphous silicon (amorphous silicon) thin film battery efficiency of 10.1%, while in practical application efficiency is slightly lower this level.

We are familiar with crystalline silicon cells into single crystal and polycrystalline, except that the silicon wafers. Monocrystalline wafers made of polysilicon raw material crystal pullers pull into a bar and then sliced into monocrystalline, polycrystalline silicon film is made of polysilicon through ingot casting furnaces made of polysilicon ingots and then sliced. Since the difference between the fabrications of polycrystalline silicon solar cell battery much. But the conversion rate, the current conversion rate of monocrystalline silicon cells generally 16% to 18% conversion rate of polycrystalline silicon cells generally 15% to 16%. From the comparison of production costs, polycrystalline silicon cells cheaper materials manufacturing simple, to save power consumption, lower overall production costs, get a lot of development. Therefore, polycrystalline silicon cells accounted for two-thirds of the amount of crystalline silicon cells, accounting for over 55% of the solar cell market share. However, although the cost of polysilicon occupies advantage, in addition to the conversion rate lower than the silicon, its service life is shorter than the Monocrystalline silicon solar cells.

- Q: Can solar cells be damaged by hail or other weather events?

- Yes, solar cells can be damaged by hail or other severe weather events. Hailstones can cause physical damage to the surface of the solar panels, leading to cracks or shattered glass. Additionally, strong winds, heavy rain, or extreme temperatures can also impact the performance and durability of solar cells. It is crucial to consider the weather conditions and take necessary precautions during the installation and maintenance of solar panels to minimize potential damage.

- Q: Can solar cells be used in emergency lighting?

- Yes, solar cells can be used in emergency lighting. Solar-powered emergency lights are designed to provide illumination during power outages or emergencies by utilizing solar panels to convert sunlight into electricity, which is then stored in batteries for later use. This makes them a reliable and sustainable option for emergency lighting solutions.

- Q: Can solar cells be used in railway applications?

- Yes, solar cells can be used in railway applications. They can be used to power various systems such as lighting, signaling, and communication equipment along railway tracks. Solar cells are reliable, cost-effective, and environmentally friendly, making them a suitable renewable energy solution for railway infrastructure.

- Q: Can solar cells be used to power electric fences?

- Yes, solar cells can be used to power electric fences. Solar panels can convert sunlight into electricity and store it in batteries, which can then be used to power the electric fence. This allows for a sustainable and reliable power source for electric fences, especially in remote locations where connecting to the grid may not be feasible.

- Q: Can solar cells be used in agricultural farms?

- Yes, solar cells can be used in agricultural farms. They can be installed on rooftops or open fields to generate clean and renewable energy. This energy can be utilized to power various agricultural operations such as irrigation systems, lighting, and machinery. Additionally, solar cells can help farms become more self-sufficient and reduce their reliance on traditional energy sources, thereby contributing to sustainable farming practices.

- Q: How do solar cells handle electromagnetic radiation?

- Solar cells are designed to efficiently convert electromagnetic radiation, particularly sunlight, into electricity. When electromagnetic radiation, such as sunlight, hits the solar cell, it excites the electrons within the cell's semiconductor material. This excitation creates an electric current, which can be harnessed as electrical energy. Therefore, solar cells are specifically designed to handle and utilize electromagnetic radiation to generate electricity.

- Q: How do solar cells contribute to reducing carbon emissions?

- Solar cells contribute to reducing carbon emissions by converting sunlight directly into electricity without producing any greenhouse gases. This renewable energy source allows us to generate clean electricity, replacing the need for fossil fuel-based power generation that emits significant amounts of carbon dioxide and other pollutants. By adopting solar cells, we can reduce our dependence on fossil fuels and mitigate the harmful effects of carbon emissions on the environment and climate change.

- Q: Is the Photovoltaic cell panel good to save the energy?

- Yes, after being used and tested for years in the market, the photovoltaic cell panel is known to be very good to save energy.

- Q: How is the solar cells factories working in China? Do they follow certain quality standards?

- Yes, they follow the standard quality assurance protocol, and they are doing very well.

- Q: How much land is required to install solar cells?

- The amount of land required to install solar cells varies depending on various factors such as the type and efficiency of the solar panels, the amount of electricity desired, and local conditions. On average, it is estimated that 1 megawatt (MW) of solar power requires approximately 5-10 acres of land. However, advancements in solar technology have led to the development of more efficient panels, reducing the land footprint needed for installation. Additionally, innovative approaches like rooftop solar panels can utilize existing structures, minimizing the need for additional land.

Send your message to us

Triple Junction Gallium Arsenide Solar Cells - Polycrystalline A Grade 3BB 156*156mm Low Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 8000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords