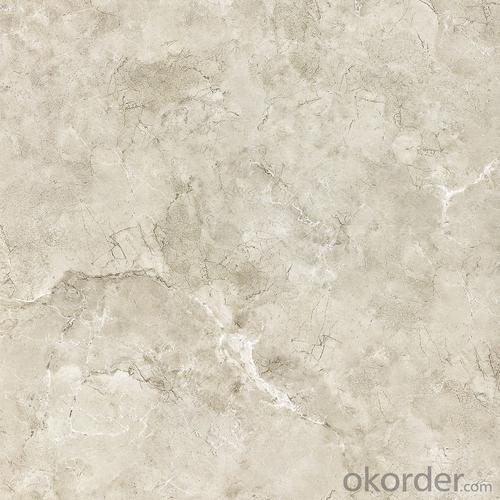

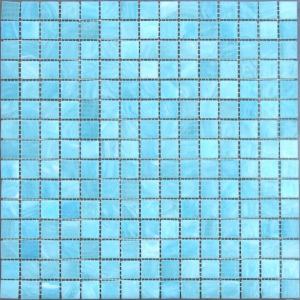

Full Polished Glazed Porcelain Tile 600 YDL6BB247

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1180.8

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Brief Introduction

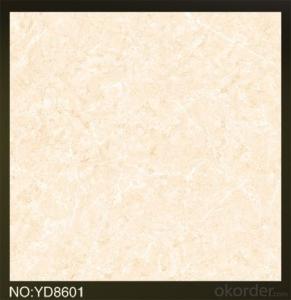

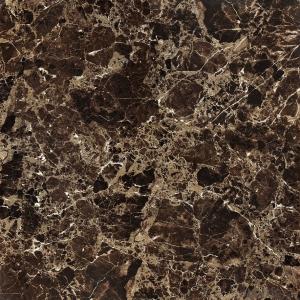

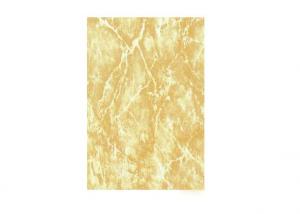

Full Polished Glazed Porcelain Tile 600 YDL6BB247 is one of the most popular color of Crystal Jade Serie, which is one serie of Polished Porcelain Tile in the present market. Just like other series, it could be used for interior floor for apartment, villa, super market as well as other public areas, due to its being high glossy and clean, homogeneous color shade as well as the reasonable price compared with natural stones.

Full glazed polished tiles are on the basis of the traditional polishing brick surface glazing and polishing products, whole set polished tile and glazed ceramic products archaize brick both advantages in one, not only glaze as smooth as polished tile brightening, like archaize brick pattern of design.

Product Features

Polished Glazed Porcelain Tile

Only Grade AAA available

Strict control on color shade, deformation, anti-pollution, surface glossy degree as well as packing

Competitive price

Standard export packing: Pater Carton+ Wooden Pallet

Fast delivery

OEM service could be offered

Marketing support on samples, catalogues as well as carton designing

Professional sales team for product, document and schedule of importing and exporting.

Product Specification

Tile Type: Polished Porcelain Tile

Quality standard: GB/T4100-2006, ISO13006, ISO9001

Water Absorption Rate: 《0.5%

Breaking Strength: 》 1800 N

Rupture Modulus: 》40 MPa

Surface Smoothness: ±0.15%

Edge Straightness: ±0.15%

Wearing Strength: 《1600 mm3

Packing Information (For 27.5 Tons heavy 20’Fcl)

For 600x600mm, 4pcs/Ctn, 40 Ctns/Pallet, 960 Ctns/20’Fcl, 1382.4m2/20’Fcl

Production Line & Package

FAQ

1. For Polished Porcelain Tile, is the 30*60 available?

—— Yes, 30*60 is available. Due to the basic size is 60*60, we need to cut 60*60 tile into 30*60. 6 pcs are packed into one carton.

2. What is the MOQ for this tile?

—— Normally the MOQ is 1382.4 m2 for one 20’ container. To support our clients, we could go with 3 models to fill one container at most.

Basic Information :

Tile Type | Full Polished Glazed Porcelain Tile |

Certificate | ISO13006, ISO9001 |

Finish | Nano Finish |

Size | 60x60mm |

Other Choices | many designs, size, colors |

- Q: the bathroom at work has lenulium sheet. I slip when it rains, b cos it is wet. I want to replace home carpeting with tiles or vynal. which one is less slippery? thanks

- ther in none slip for both products. shop around

- Q: The tile is attached to sheetrock and I don‘t want to damage the sheetrock by ripping off the old tile.

- NO!!!! the top tile will crack if you do that do not do that it will be super expensive to get it fixed

- Q: I understand most of the rules of pai gow tiles, but one part that I am not clear on is banking. If I am the banker, do I get to see the ways that the players set their tiles before I set mine? Or do I secretly set my tiles just like everyone else and then we all reveal simultaneously?

- yes to main question

- Q: What is the white powder on the back of the floor tiles?

- It is in the kiln before the application of the brick at the end of glaze, the main component is alumina, the purpose is to avoid the tiles in the high temperature state stick furnace roll bar, resulting in tile deformation and blocking the kiln and cause roller break. Paving when the water brush on the line

- Q: I‘m going to install a porcelain tile floor. My question is when I install a tile up against a cabinet that people can see. Should I but the tile up against the cabinet or should I leave enough space to grout between the tile and the cabinet. Just wondering what the standard practice is , and what looks the best. Also I have a small crack in the concrete, which the tile company said it was so minor that not to worry about it. Although it caused a crack in my old tile that was originally installed. I would really like to prep the crack prior to installing the new tile. What would you recommend doing to prep the crack. Thanks

- If at all possible remove the cabinet and tile under it this way you will have a new clean and level floor otherwise you are leaving a quarter inch drop off at the least for water,bacteria and mold to grow. As for the crack if you have a circular saw buy an in-expensive carborundum blade or mmasonryfor it then grove out the crack and use a hand chisel wherever you can't reach or use a hammer and mmasonrygouging chisel for the whole crack,diamond wheels on grinders work well also if you have one,then wire wheel or wire brush out the grove and vvacuumit thoroughly then put silicone in it to just below level then using your thin set mix enough to apply a thin layer to each side of the crack and level out the crack then use fiberglass drywall tape and possibly a geo grid type netting or vvinylscreening, if the slab is older and somewhat settled this is the only way without busting out the slab which is probably only 3 inch thick,and pouring a new 6 bag per yard high strength concreteon a vvibratortamped ssubstrate withvapor barriers.

- Q: I would like to glue it to the tile that is already there, except remove a few that are coming loose.

- yes, but, if theres already some of the old tile coming up, may be a goo idea to take all of it up. if it is only a couple of pieces just pull them and fill in with leveling compound

- Q: I am installing 4.5 x 4.5 porcelain tiles on a drywall kitchen backsplash. Applying Omnigrip mastic using a 1/4 x 3/16 vnotch trowel. The tiles have a waffle grid pattern on the back which is about 1/16 deep. I tested the application of one tile and noticed that the mastic did not fill all the waffle depressions. Are they supposed to be all filled? DO I have to backbutter the tiles? Am I using the correct trowel size? Please help!P.S. What is the purpose of the waffle pattern in the first place?

- Forgive okorder /

- Q: My mothers house has 9 tiles on her bathroom floor and I understand they are made with asbestos. Some of the tiles are starting to lift and I am concerned about how to remove and dispose of them, any suggestions?

- I would not advise you do it yourself. If you really need to DIY. soak the tiles and dont break them and you can hire a special type of skip i think. Experts are the best for this job, expensive but not as expensive as your life!!

- Q: A few tiles in my building flat give a cracking noise when i step on them.Upon inspection i found that the tiles make cracking sound even when i press them with my hands but requires some strength.There is a small airgap in a few joints but the gap is very small.The tiles were installed almost 15 years ago and i dont know how old the building is but is considered an earthquake proof structure.The cracking sound is sometimes even for as long as 1-2 seconds when standing on it.So is it a lose tile or a foundation crack?

- You say the tile floor was installed about 15 years ago, which would make me think that the thin-set mastic used to adhere the tiles to the floor has dried out and allowed several of the tiles to loosen on the mastic bed. This allows them to move, albeit ever so slightly, each time you step on them. If the problem is not resolved soon the cracking sound will increase and there's a good chance the tiles themselves will crack and then need to be completely replaced. This could be sort of difficult seeing as how you'd be attempting to match 15 year old patterns. The repair is to remove the affected tiles, then remove the old thin-set mastic, being careful not to disturb the surrounding tiles, reapply new mastic and then re-set the tiles. Allow them to set overnight, undisturbed and the next day re-grout the cracks. If you don't feel comfortable doing the repairs or if it's not your building, either get your landlord involved or hire a flooring guy yourself.

- Q: I found answers about laying tile and a backer board over linoleum I didn‘t know if they would be the same. What would cause tile to crack if it‘s places directly on concrete?

- Go to a Tile Store. They now have Ceramic Tile which can be put on top of other flooring as long as the floor is level. Some of these Tiles can be snapped together. No Mud, no Grout.They look wonderful.

Send your message to us

Full Polished Glazed Porcelain Tile 600 YDL6BB247

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1180.8

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches