FRP Pultrusion Profiles Molded Gratings / GRP Grating with Great Shape

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

FRP Molded Grating is a structural panel which uses high-strength E-Glass roving as reinforcing material, thermosetting resin as matrix and then casted and formed in a special metal mold. It provides properties of light weight, high strength, corrosion resistance, fire resistance and anti-skid. FRP Molded Grating is widely used in oil industry, power engineering, water & waste water treatment, ocean survey as working floor, stair tread, trench cover, etc. and is an ideal loading frame for corrosion circumstances.

Feature

Corrosion Resistance

- Aging Resistance

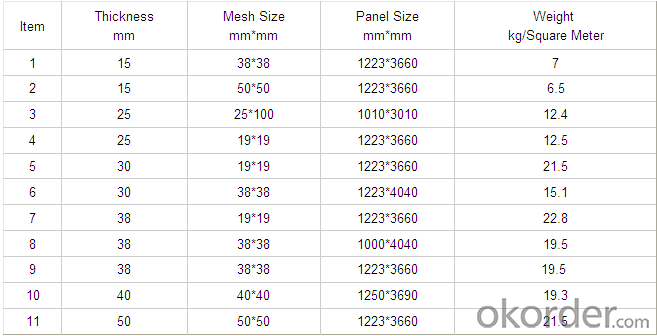

Specification

Advantage

coated with prevent aging layer

- high strength

long service life

easy installation

Application

Power plants, substation equipment enclosures, antimagnetic, anti-static,to prevent small animals into the equipment failure, as there is electricity facilities and without power interval intervals.

In high voltage electrical equipment for power line work, in order to prevent workers go wrong location, charged interval or near electrically charged equipment to dangerous distance.

- All kinds of building maintenance section

FAQ

1. Do You Arrange Shipment?

Yes, dear esteemed customers, for FOB or CIF price, we will arrange shipment for you. For EXW price, clients need to arrange shipment by themselves or their agents.

2. How is the package?

Usually, we arrange the standard out-package for exporting.

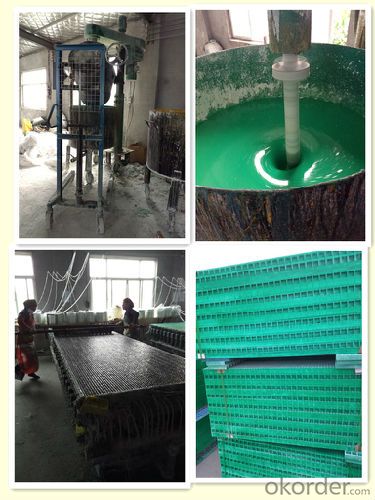

PROCESS

FACTORY

- Q: Are FRP pultrusion profiles resistant to jet fuel?

- Yes, FRP pultrusion profiles are generally resistant to jet fuel.

- Q: Are FRP pultrusion profiles resistant to hail or impact damage?

- FRP pultrusion profiles exhibit exceptional resistance to both hail and impact damage. The incorporation of reinforcing fibers such as carbon or glass, along with a polymer resin matrix, grants these profiles unparalleled strength and durability. When compared to materials like wood, steel, or aluminum, FRP pultrusions offer significantly superior impact resistance. These profiles are specifically engineered to endure even the harshest environmental conditions, including hailstorms. The composite composition of FRP enables it to effectively absorb and distribute the energy generated by impacts, effectively preventing the formation of cracks or fractures. As a result, they are an ideal choice for various applications that necessitate protection against hail or impact damage, such as building facades, bridges, handrails, and utility poles. Moreover, FRP pultrusion profiles possess an impressive strength-to-weight ratio, meaning they can withstand heavy impacts without undermining their structural integrity. Furthermore, they are non-corrosive, making them impervious to rust or degradation caused by hail or impact. To summarize, the composite construction and exceptional strength-to-weight ratio of FRP pultrusion profiles render them highly resistant to hail or impact damage. They offer a reliable and long-lasting solution for applications that demand durability and resilience in the face of harsh environmental conditions.

- Q: Can FRP pultrusion profiles be used in the construction of water treatment plants?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in the construction of water treatment plants. FRP pultrusion profiles offer several advantages such as high strength-to-weight ratio, corrosion resistance, and durability, making them well-suited for water treatment plant applications. These profiles can be used in various structural components like beams, columns, grating, and handrails, providing a cost-effective and long-lasting solution for the construction of water treatment plants.

- Q: Can FRP pultrusion profiles be used in the water and wastewater treatment industry?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in the water and wastewater treatment industry. FRP pultrusion profiles are highly durable, corrosion-resistant, and have excellent mechanical properties, making them suitable for various applications in the water and wastewater treatment industry. One of the main advantages of FRP pultrusion profiles is their resistance to corrosion. Water and wastewater treatment facilities often deal with aggressive chemicals, high humidity, and corrosive environments. Traditional materials like steel or wood may deteriorate and require frequent maintenance or replacement. However, FRP pultrusion profiles are specifically designed to withstand harsh conditions without corrosion, ensuring long-term performance and reducing maintenance costs. Additionally, FRP pultrusion profiles offer excellent strength-to-weight ratio, making them ideal for structural applications in water and wastewater treatment facilities. They can be used as walkways, handrails, grating, ladders, and other structural components. The lightweight nature of FRP profiles allows for easy installation and minimizes the load on the supporting structures. Furthermore, FRP pultrusion profiles are non-conductive, providing an added safety benefit in water and wastewater treatment facilities. This property is particularly important when dealing with electrical equipment or applications near water sources, reducing the risk of electrical hazards. Moreover, FRP pultrusion profiles can be customized to meet specific design requirements, including different shapes, sizes, and colors. This flexibility allows for greater design freedom, ensuring that the profiles can be tailored to fit the specific needs of water and wastewater treatment projects. Overall, the use of FRP pultrusion profiles in the water and wastewater treatment industry offers numerous advantages, including corrosion resistance, high strength, lightweight, non-conductivity, and design flexibility. These qualities make FRP profiles a reliable and cost-effective choice for various applications in this industry.

- Q: Can FRP pultrusion profiles be used in agricultural structures?

- Yes, FRP pultrusion profiles can certainly be used in agricultural structures. They offer several advantages such as high strength-to-weight ratio, corrosion resistance, and durability, making them suitable for various applications in the agricultural industry. These profiles can be used in structures like greenhouse frames, livestock enclosures, support beams, fencing, and other agricultural infrastructure.

- Q: Are FRP pultrusion profiles resistant to impact?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are generally resistant to impact. The combination of the high-strength fibers and the polymer matrix used in the manufacturing process makes FRP profiles highly durable and able to withstand significant impacts without cracking or breaking. Additionally, the pultrusion process ensures that the fibers are uniformly distributed throughout the profile, further enhancing its impact resistance. This makes FRP pultrusion profiles ideal for applications where impact resistance is important, such as in construction, transportation, and infrastructure projects.

- Q: Can FRP pultrusion profiles be used in the construction of outdoor signage?

- Certainly, outdoor signage can utilize FRP pultrusion profiles. These profiles possess remarkable qualities, including durability, strength, and the ability to withstand different environmental conditions, rendering them ideal for outdoor use. Typically, these profiles consist of a combination of fiberglass reinforcement and resin matrix, resulting in a lightweight yet robust material. Outdoor signage often confronts harsh weather conditions, such as rain, sun exposure, and temperature fluctuations. FRP pultrusion profiles exhibit excellent resistance to corrosion, UV rays, and moisture, ensuring that the signage retains its structural integrity and visual appeal over time. Moreover, FRP pultrusion profiles offer customization options to fulfill specific design requirements, offering flexibility in creating distinctive and captivating outdoor signage. These profiles can be effortlessly shaped, cut, and assembled, making them a versatile choice for signage applications. In essence, the construction of outdoor signage can undoubtedly benefit from the use of FRP pultrusion profiles due to their durability, resistance to environmental conditions, and design flexibility.

- Q: Can FRP pultrusion profiles be used in the construction of railway platforms?

- Indeed, railway platforms can be constructed using FRP (Fiber Reinforced Polymer) pultrusion profiles. These profiles possess numerous advantages that render them suitable for this particular application. To begin with, FRP pultrusion profiles exhibit a combination of lightweight and high durability. Consequently, they are well-suited for railway platforms as they can withstand heavy loads and frequent foot traffic without experiencing significant deformation or degradation over time. Moreover, FRP pultruded profiles boast exceptional corrosion resistance. This feature is particularly crucial for railway platforms, which frequently encounter harsh environmental conditions such as rain, snow, and salt. Unlike traditional materials like steel or wood, FRP does not undergo rust or rot, ensuring a longer lifespan for the platform. Additionally, FRP pultrusion profiles offer versatility in design. They can be customized to meet specific dimensional and structural requirements, facilitating the creation of platforms in various shapes and sizes. This adaptability proves beneficial for railway platforms, which often need to be tailored to fit the available space and accommodate specific railway configurations. Furthermore, FRP pultrusion profiles possess excellent electrical insulation properties. This attribute is vital for railway platforms, as they necessitate electrical isolation from the tracks to prevent electrical shocks and guarantee passenger safety. Lastly, FRP pultrusion profiles are convenient to install and require minimal maintenance. They can be prefabricated off-site and rapidly assembled on-site, thereby reducing construction time and costs. Furthermore, FRP does not demand regular painting or sealing, resulting in time and cost savings in terms of maintenance. In conclusion, due to their lightweight nature, durability, corrosion resistance, design flexibility, electrical insulation properties, and ease of installation and maintenance, FRP pultrusion profiles serve as a viable option for constructing railway platforms.

- Q: Can FRP pultrusion profiles be used in the construction of stadium seating?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in the construction of stadium seating. FRP pultrusion profiles have several advantages that make them suitable for this application. Firstly, FRP pultrusion profiles are lightweight yet strong, which is ideal for stadium seating where a large number of seats need to be installed. The lightweight nature of FRP profiles makes them easier to handle and install, reducing the time and effort required for construction. Secondly, FRP pultrusion profiles are highly durable and resistant to corrosion, making them suitable for outdoor applications like stadium seating. They are not prone to rusting, rotting, or degradation from exposure to moisture, UV rays, or chemicals commonly found in stadiums. Additionally, FRP pultrusion profiles are non-conductive, providing an added safety benefit, especially in areas where electrical wiring may be present. This reduces the risk of electric shocks or accidents that can occur with conductive materials. Furthermore, FRP pultrusion profiles can be customized to meet specific design requirements, allowing for flexibility in designing stadium seating layouts. They can be manufactured in various shapes, sizes, and colors to match the aesthetic and functional requirements of the stadium. Lastly, FRP pultrusion profiles have a long service life with low maintenance requirements, reducing the overall cost of ownership for stadium seating. This makes them a cost-effective choice in the long run. In conclusion, FRP pultrusion profiles are an excellent choice for the construction of stadium seating due to their lightweight, durable, non-conductive, customizable, and cost-effective nature.

- Q: Are FRP pultrusion profiles resistant to chemical spills or leaks?

- FRP pultrusion profiles are known for their high resistance to chemical spills or leaks, making them an excellent choice for construction projects. One of the main benefits of using FRP as a building material is its exceptional chemical resistance. These profiles are made by impregnating continuous fibers with a thermosetting resin, resulting in a durable composite material. The selection of the resin used in FRP pultrusion profiles depends on the specific chemical environment they will be exposed to. This allows for customization and optimization of the composite's ability to withstand different chemicals. Additionally, the fibers used in FRP are typically chemically inert, further enhancing the profiles' resistance to chemical spills or leaks. FRP pultrusion profiles have proven to be highly resistant to a wide range of chemicals, including acids, alkalis, solvents, and corrosive substances. They are commonly used in industries such as chemical processing, water and wastewater treatment, oil and gas, and marine applications, where exposure to aggressive chemicals is common. Apart from their chemical resistance, FRP pultrusion profiles offer several other advantages. They are lightweight yet strong and stiff, making them ideal for applications that require structural integrity. They are also non-conductive, non-magnetic, and have excellent electrical insulation properties. Overall, FRP pultrusion profiles are a reliable option for environments where chemical spills or leaks are a concern. They provide robust resistance to a wide variety of chemicals, ensuring long-lasting performance and minimal maintenance requirements.

Send your message to us

FRP Pultrusion Profiles Molded Gratings / GRP Grating with Great Shape

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords