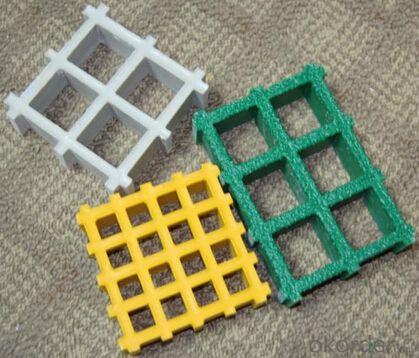

FRP Pultrusion Profiles GRP Molded Grid for Car Washing

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 30000 m2 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product description of FRP Grating

FRP Grating,Comparing with other floor materials, FRP molded grating provides a series of benefits, unmatched impact resistance,

while the strength-weight-ratio is only one-fourth of that of steel grating. It is easy to cut and install.

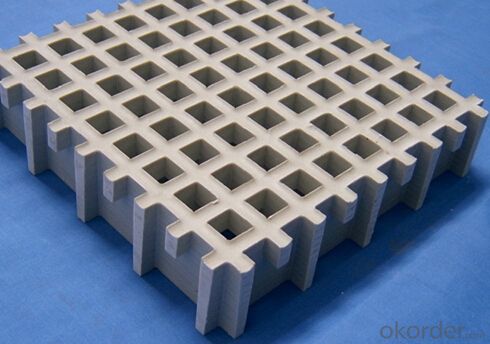

Specification of FRP Grating

Item | Thickness mm | Mesh Size mm*mm | Panel Size mm*mm | Weight kg/Square Meter |

01 | 15 | 38*38 | 1223*3660 | 7 |

02 | 15 | 50*50 | 1223*3660 | 6.5 |

03 | 25 | 25*100 | 1010*3010 | 12.4 |

04 | 25 | 19*19 | 1223*3660 | 12.5 |

05 | 30 | 19*19 | 1223*3660 | 21.5 |

06 | 30 | 38*38 | 1223*4040 | 15.1 |

07 | 38 | 19*19 | 1223*3660 | 22.8 |

08 | 38 | 38*38 | 1000*4040 | 19.5 |

09 | 38 | 38*38 | 1223*3660 | 19.5 |

10 | 40 | 40*40 | 1250*3690 | 19.3 |

11 | 50 | 50*50 | 1223*3660 | 21.5 |

Images

Features

1.Corrosion and Chemical resistant

2.Slip-resistant

3.High strength-to-weight ratio

4.Ergonomic

5.Low maintenance

6.Fire retardant

7.Easily fabricated and installed

FAQ:

1. Why Choose us?

CNBM is a stated own company, provide the guarantee for the best quality, best service and safety business.

2. How will we guarantee the quality?

a, ISO 9001-2008 quality control system;

b, Strict and regular quality control in production;

c, Inspeciation when loading into container before shippment;

d, Sample stock for one year for quality tracing and record.

3. Payment terms?

We can accept L/C, T/T etc.

- Q: Can FRP pultrusion profiles be used in the construction of wind turbine blades?

- Indeed, FRP pultrusion profiles have the capability to be utilized in the construction of wind turbine blades. There are several advantages offered by FRP pultrusion profiles that render them suitable for this purpose. To begin with, FRP pultrusion profiles possess a lightweight yet robust nature, a crucial characteristic for wind turbine blades since they must endure the aerodynamic forces exerted by the wind. The high strength-to-weight ratio of FRP pultrusion profiles permits the creation of longer and more effective blades. Moreover, FRP pultrusion profiles exhibit exceptional corrosion resistance properties, a vital attribute for wind turbines that are exposed to harsh weather conditions. In contrast to traditional materials like steel, FRP does not corrode, thereby ensuring an extended service life for the wind turbine blades. Additionally, FRP pultrusion profiles are customizable to satisfy specific design requirements. This flexibility allows for the optimization of blade performance by tailoring the shape, thickness, and stiffness of the profiles to maximize energy capture and minimize fatigue. Furthermore, FRP pultrusion profiles possess good fatigue resistance, enabling them to endure repeated loading cycles without experiencing significant performance degradation. This is particularly crucial for wind turbine blades, which encounter cyclic loading due to wind gusts and changes in wind direction. Lastly, FRP pultrusion profiles are electrically non-conductive, a beneficial trait for wind turbine blades as it eliminates the risk of electrical discharge during operation. In conclusion, the lightweight, strong, corrosion-resistant, and customizable nature of FRP pultrusion profiles makes them an outstanding choice for the construction of wind turbine blades. This contributes to the advancement of more efficient and durable wind energy systems.

- Q: Are FRP pultrusion profiles resistant to chemical spills or leaks?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are highly resistant to chemical spills or leaks. The combination of the fiberglass reinforcement and the polymer matrix used in FRP pultrusion provides excellent resistance to a wide range of chemicals, acids, and corrosive substances. This makes FRP pultrusion profiles a suitable choice for applications where chemical resistance is crucial, such as in chemical processing plants, wastewater treatment facilities, and storage tanks.

- Q: What are the maintenance requirements for FRP pultrusion profiles?

- FRP pultrusion profiles have low maintenance requirements due to their durability and resistance to corrosion. They are a low-maintenance choice for various applications. However, there are a few important maintenance practices that can help prolong their lifespan and ensure optimal performance. Firstly, it is important to periodically clean the profiles to remove dirt, dust, and debris. This can be achieved by using a mild detergent solution and a soft brush or cloth. It is advisable to avoid abrasive cleaners or materials that could scratch the surface. Regular visual inspections should also be conducted to identify any signs of damage or wear. Cracks, chips, delamination, or any other visible defects should be promptly addressed to prevent further damage. While FRP pultrusion profiles are generally resistant to UV radiation, prolonged exposure to direct sunlight can cause some degradation. Applying a UV protective coating or using a UV-resistant paint can minimize the effects of UV exposure and extend the profiles' lifespan. For pultrusion profiles with moving parts or connections, such as hinges or joints, it is important to apply a suitable lubricant to ensure smooth operation and prevent friction-related issues. It is crucial to use lubricants compatible with FRP materials to avoid any adverse chemical reactions. In the event of significant damage or wear, it may be necessary to repair or replace the affected sections of the FRP pultrusion profiles. Trained professionals with experience working with FRP materials should perform this task to ensure proper repair techniques and maintain structural integrity. In conclusion, while FRP pultrusion profiles require minimal maintenance, regular cleaning, inspection, and prompt addressing of issues are crucial for their longevity and optimal performance. By following these maintenance practices, the lifespan of FRP pultrusion profiles can be maximized while maintaining their structural integrity over time.

- Q: Can FRP pultrusion profiles be customized according to specific requirements?

- Yes, FRP pultrusion profiles can be customized according to specific requirements. Pultrusion is a manufacturing process that allows for the creation of complex shapes and sizes, making it possible to tailor the FRP profiles to meet specific design and performance criteria. This customization can include modifications in dimensions, reinforcement types, resin systems, color, surface finish, and various other parameters to ensure they meet the desired specifications and needs of the application.

- Q: Are FRP pultrusion profiles resistant to automotive fluids?

- Yes, FRP pultrusion profiles are generally resistant to automotive fluids. The inherent chemical resistance and durability of the fiberglass-reinforced plastic make it suitable for withstanding exposure to various automotive fluids such as oils, fuels, and coolants. However, it is essential to consider the specific type of fluid and consult the manufacturer's guidelines to ensure the optimal performance and longevity of the FRP profiles in automotive applications.

- Q: Can FRP pultrusion profiles be used in oil and gas applications?

- Yes, FRP (Fiber Reinforced Plastic) pultrusion profiles can be used in oil and gas applications. FRP materials have excellent corrosion resistance, high strength-to-weight ratio, and low maintenance requirements, making them suitable for various demanding environments, including oil and gas. Additionally, FRP pultrusion profiles can be customized to meet specific requirements, such as resistance to chemicals, high temperatures, and fire.

- Q: Do FRP pultrusion profiles require regular maintenance?

- No, FRP pultrusion profiles do not require regular maintenance. They are highly durable and resistant to corrosion, rot, and other environmental factors. This makes them ideal for applications requiring low maintenance and long-term reliability.

- Q: Are FRP pultrusion profiles resistant to moisture?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are highly resistant to moisture. The manufacturing process of FRP pultrusion involves impregnating fiberglass reinforcements with a resin matrix, typically polyester, vinyl ester, or epoxy. These resins are inherently moisture-resistant, making FRP pultrusion profiles suitable for various applications that involve exposure to moisture or humid environments. Unlike traditional materials like wood or steel, FRP does not absorb water, which eliminates the risk of swelling, warping, or corrosion. This moisture resistance is particularly advantageous in applications such as construction, infrastructure, and marine industries, where the profiles may be exposed to rain, saltwater, or high humidity. Additionally, the resin matrix used in FRP pultrusion can be further enhanced with additives or coatings to provide even greater moisture resistance. For example, UV inhibitors can be added to protect against degradation caused by sunlight exposure. Fire-retardant coatings may also be applied to meet specific safety requirements. Overall, FRP pultrusion profiles offer excellent resistance to moisture, making them a durable and reliable choice for various applications where moisture exposure is a concern.

- Q: Are FRP pultrusion profiles resistant to chemicals used in food processing?

- Yes, FRP (Fiber Reinforced Plastic) pultrusion profiles are highly resistant to chemicals used in food processing. They are specifically engineered to withstand harsh chemical environments, including the cleaning and sterilization agents commonly used in food processing facilities. This resistance makes FRP pultrusion profiles a suitable material choice for various applications in the food industry where chemical resistance is crucial.

- Q: Can FRP pultrusion profiles be used in modular construction?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can definitely be used in modular construction. FRP profiles are lightweight, high-strength, corrosion-resistant, and have excellent thermal and electrical insulating properties. These characteristics make them ideal for use in modular construction, where the emphasis is on prefabrication, transportation, and rapid assembly. The use of FRP pultrusion profiles in modular construction offers several advantages. First, their lightweight nature makes them easy to handle and transport, reducing logistical costs and effort. Second, their high strength-to-weight ratio ensures structural integrity while minimizing the overall weight of the modular components. This is particularly beneficial in applications where weight reduction is crucial, such as rooftop installations or areas with limited load-bearing capacity. Furthermore, the corrosion resistance of FRP profiles eliminates the need for regular maintenance and extends the lifespan of the modular construction. This is particularly advantageous in harsh environments, such as coastal areas or chemical processing facilities, where traditional construction materials like steel may deteriorate quickly. Additionally, FRP pultrusion profiles can be easily customized to meet specific design requirements. They can be manufactured in various shapes, sizes, and colors, allowing for flexibility in modular construction design. The profiles can also be easily integrated with other construction materials, such as concrete or wood, providing compatibility with existing modular systems. In summary, FRP pultrusion profiles are highly suitable for modular construction due to their lightweight, high strength, corrosion resistance, and customization capabilities. Their use in modular construction can enhance efficiency, reduce costs, and improve the overall performance and durability of modular buildings and structures.

Send your message to us

FRP Pultrusion Profiles GRP Molded Grid for Car Washing

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 30000 m2 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords