FRP Pultrusion Profiles:Latest Styles Anti-Ageing High-Quality FRP Pultruded Grating with Competitive Prices

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 300000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PRODUCT DESCRIPTION

Pultruded grating is made by a particular assembly process, which using “I” shape as its main load-bearing and special rod to go through the bearing bar. Pultruded grating include the standard grating and the custom grating, the custom grating can be designed to meet customer’s requirement or special using condition by changing the shape, size and space of the bearing bars, the surface can be covered with lozenge panel, grit panel, or added the anti-slippery sand directly.

SPECIFICATION

Thickness (mm) | Bar width (mm) | Open space (mm) | Open rate (%) | Approx weight (kg/m |

25.4 | 15.2 | 22.8 | 60 | 13.2 |

25.4 | 15.2 | 15.2 | 50 | 15.9 |

25.4 | 15.2 | 10.1 | 40 | 18.5 |

25.4 | 40 | 10.8 | 21 | 14.5 |

38.1 | 15.2 | 22.8 | 60 | 15.8 |

38.1 | 15.2 | 15.2 | 50 | 19.1 |

38.1 | 15.2 | 10.1 | 40 | 22.4 |

50.8 | 25.4 | 25.4 | 50 | 16.6 |

50.8 | 25.4 | 12.7 | 33 | 21.1 |

CHOICE FOR PULTRUDED GRATING

Resin: GP resin, ISO resin, VE resin, Phenol resin

Color choice: Yellow, gray, green, custom color

Surface choice: Groove surface, grit surface, lozenge cover surface

FEATURES

a. Anti-corrosion and anti-rust

b. Light weight and high strength

c. Anti-flammable

d. Anti- fatigue

e. Safe and anti-slippery

f. Anti-ageing

g. Easy of maintenance

h. Excellent electromagnetism property

i. Good economic benefit

FIELDS SERVED

Sewage treatment,

water supply and drainage,

chemical industry,

oil industry,

power engineering,

pulp and paper,

construction engineering,

spinning, marine engineering.

APPLICATION

Operation terrace,

stair walkway,

ground floor,

trench cover,

sidewalk,

foot bridge,

equipment safety fence,

scaffold.

COMPANT DESCRIPTION

CNBM,China National Building Materials Group is a state-owned enterprise in charge of administrative affairs in china building materials industry. Established in 1984, CNBM is a large group corporation of building materials with total assets of 25 billion RMB and a total staff of 30,000.CNBM now owns 200 subordinating firms of solely owned and joint-venture companies.

CNBM International Corporation is one subsidiary of CNBM, we focus on offering good-quality products,professional service and complete solution to our customers. Strong delivery capacity, advanced technology& management, strong financing capability and excellent after-sale service are our advantages in sharing international market.

FAQ

1.Q:Are you factory or trading company ?

A:We are Factory produce FRP machines and FRP products.

2.Q:If can customized by customers requirements?

A:yes,we can produce the machine with customized size.

3.Q:How about the payment?

A:We accept any kind of payment.

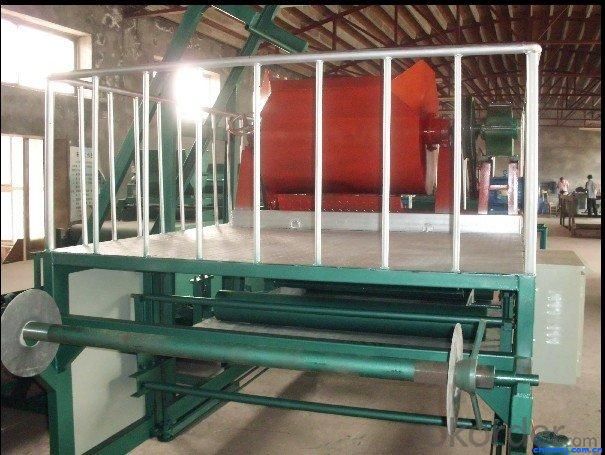

PICTURES

- Q: How do FRP pultrusion profiles perform in earthquake-prone areas?

- When it comes to performance in earthquake-prone areas, FRP (Fiber Reinforced Polymer) pultrusion profiles have numerous advantages. To start with, their high strength-to-weight ratio is well-known. This means that they are lightweight compared to traditional construction materials like steel or concrete, yet still offer significant strength. This characteristic is crucial in earthquake-prone areas as it reduces the overall mass of the structure, minimizing the inertial forces generated during seismic events. As a result, FRP profiles can effectively withstand and absorb the energy released during an earthquake, reducing the risk of structural damage or collapse. Additionally, FRP pultrusion profiles exhibit excellent durability and resistance to corrosion. Unlike steel, they are not susceptible to rust or other forms of degradation caused by moisture or chemicals commonly found in earthquake-prone areas. This resistance to corrosion ensures the long-term performance and reliability of FRP profiles, minimizing the need for costly maintenance and repairs. Furthermore, FRP pultrusion profiles demonstrate high flexibility and ductility. These characteristics allow them to deform and absorb energy without fracturing or breaking, which is particularly advantageous during seismic events. By dissipating the energy generated by the earthquake, FRP profiles help protect the integrity of the structure and prevent catastrophic failures. Lastly, FRP pultrusion profiles are non-conductive materials, meaning they do not conduct electricity. This feature is important in earthquake-prone areas where electrical infrastructure can be vulnerable to damage. The non-conductive nature of FRP profiles reduces the risk of electrical faults or fires caused by seismic activity. In conclusion, FRP pultrusion profiles provide a range of performance advantages in earthquake-prone areas. Their lightweight, high strength, durability, flexibility, and non-conductive properties make them a reliable and effective choice for construction in regions prone to seismic activity.

- Q: How do FRP pultrusion profiles perform in high-temperature applications?

- FRP pultrusion profiles have gained recognition for their exceptional performance in high-temperature scenarios. Through the combination of reinforcement fibers and the polymer matrix utilized in the pultrusion process, these profiles possess a remarkable ability to maintain their structural integrity and thermal stability. The primary advantage of FRP pultrusion profiles in high-temperature applications lies in their capacity to endure elevated temperatures without compromising their structural integrity. Unlike traditional materials such as steel or aluminum, which may experience deformation or failure under high temperatures, FRP pultrusion profiles retain their shape and performance. The specific performance of FRP pultrusion profiles in high-temperature applications relies on the selection of reinforcement fibers and the polymer matrix employed. Different fibers, such as glass, carbon, or aramid, possess varying thermal resistance properties. By selecting the appropriate fiber type and resin system, manufacturers can customize FRP pultrusion profiles to withstand specific temperature ranges. Furthermore, FRP pultrusion profiles showcase low thermal conductivity, meaning they are not as efficient in conducting heat as metals. This attribute makes them well-suited for insulation applications as they aid in minimizing heat transfer and preserving a stable temperature environment. Additionally, FRP pultrusion profiles exhibit resistance to corrosion, which proves particularly advantageous in high-temperature environments where metals tend to corrode more rapidly. Their corrosion resistance ensures long-term durability and reduces maintenance requirements. To summarize, FRP pultrusion profiles excel in high-temperature applications due to their structural integrity, thermal stability, low thermal conductivity, and corrosion resistance. Manufacturers can tailor the material composition to meet specific temperature requirements, making FRP pultrusion profiles a reliable choice for various industries, including aerospace, automotive, chemical processing, and oil and gas.

- Q: What are the different shapes and sizes of FRP pultrusion profiles available?

- There is a wide selection of FRP pultrusion profiles, which come in various shapes and sizes, to accommodate different applications and industries. Some of the commonly found shapes are as follows: 1. Square and rectangular profiles: These profiles are utilized in construction, infrastructure, and industrial sectors, and they come in different dimensions. They possess exceptional structural strength and can serve as beams, columns, or other load-bearing components. 2. Round profiles: Round FRP pultrusion profiles are frequently employed as structural supports, handrails, and guardrails. They are available in different diameters to suit specific requirements. 3. I-beams: FRP I-beams are well-liked in the construction field because of their high strength-to-weight ratio. They are commonly used as structural members, supporting elements, or floor joists. 4. Channel profiles: Channel-shaped FRP profiles are utilized in applications that demand a combination of strength and versatility. They find use in cable trays, equipment supports, and framing systems. 5. Angle profiles: FRP angle profiles are commonly used as reinforcements or supports in construction and industrial settings. They provide stability and structural integrity to various components. 6. Custom profiles: In addition to the standard shapes mentioned above, FRP pultrusion profiles can be tailor-made to meet specific requirements. Manufacturers have the capability to create profiles with unique shapes and sizes that cater to the needs of different applications. It is worth noting that the availability of shapes and sizes may differ among manufacturers. Therefore, it is advisable to consult suppliers or manufacturers to determine the specific range of FRP pultrusion profiles they offer.

- Q: Can FRP pultrusion profiles be used in the agricultural and farming industry?

- Absolutely, FRP pultrusion profiles are indeed applicable in the agricultural and farming sector. Recognized for their exceptional strength, durability, and corrosion resistance, these profiles are highly suitable for outdoor and challenging environments typically found in this industry. A variety of agricultural and farming applications can benefit from these profiles, including: 1. Fencing and enclosures: By employing FRP pultrusion profiles, strong and enduring fences, gates, and enclosures can be created for safeguarding livestock and crops. These profiles possess resistance against rot, rust, and insect damage, ensuring reliable protection for animals and crops. 2. Structural components: Agricultural buildings, sheds, and greenhouses can utilize FRP pultrusion profiles as structural components. Thanks to their impressive strength-to-weight ratio, lightweight and durable structures can be constructed, capable of withstanding extreme weather conditions. 3. Irrigation systems: FRP pultrusion profiles can be harnessed for the construction of irrigation systems, including pipes, channels, and culverts. These profiles are non-corrosive with a smooth interior surface, reducing friction and improving water flow efficiency. 4. Equipment support and framing: Various agricultural equipment, such as conveyors, platforms, and machinery, can benefit from the support and framing provided by FRP pultrusion profiles. Their superior strength and stiffness make them suitable for heavy-duty applications. 5. Animal housing and equipment: Animal housing and equipment, such as pens, stalls, and feeding troughs, can be constructed using FRP pultrusion profiles. These profiles offer resistance against chemicals, moisture, and UV radiation, resulting in a long lifespan and low maintenance requirements. In conclusion, the outstanding mechanical properties, resistance to environmental factors, and versatility offered by FRP pultrusion profiles make them an excellent choice for the agricultural and farming industry.

- Q: What is the shear strength of FRP pultrusion profiles?

- The shear strength of FRP pultrusion profiles can vary depending on various factors such as the specific type of resin used, the reinforcement material, and the design of the profile. However, in general, FRP pultrusion profiles have high shear strength compared to traditional materials like steel or aluminum. The shear strength typically ranges from 50 to 150 MPa, making them suitable for various structural applications.

- Q: Are FRP pultrusion profiles resistant to caustic solutions?

- FRP pultrusion profiles are known for their resistance to caustic solutions. The combination of reinforcing fibers and the polymer matrix used in FRP pultrusion provides exceptional chemical resistance. Unlike traditional materials like steel or wood, which can be corroded or degraded by strong alkaline substances, FRP pultrusion profiles are highly resistant to chemical attack. This makes them suitable for industries that frequently encounter caustic solutions, such as chemical processing, wastewater treatment, and marine environments. However, it is important to refer to the manufacturer's specifications and guidelines to ensure compatibility between specific caustic solutions and the chosen FRP pultrusion profile.

- Q: Are FRP pultrusion profiles resistant to hydrochloric acid?

- FRP pultrusion profiles exhibit a general resistance to hydrochloric acid. The corrosion resistance of FRP materials varies based on the specific resin and fiber used during manufacturing. Nevertheless, most FRP pultrusion profiles are designed to endure exposure to a wide array of chemicals, including hydrochloric acid. The corrosion resistance of FRP is attributed to the chemical inertness of the resin matrix, typically composed of polyester, vinyl ester, or epoxy. These resins form a protective barrier against chemical attack, allowing FRP profiles to maintain their structural integrity even in harsh surroundings. However, the level of resistance may fluctuate depending on the concentration and temperature of the hydrochloric acid. In instances of high concentration or elevated temperatures, the resistance may diminish. It is always recommended to refer to the manufacturer's specifications or seek expert advice to ensure the suitability of FRP pultrusion profiles for specific acid concentrations and temperature ranges. In conclusion, FRP pultrusion profiles are renowned for their exceptional chemical resistance and are frequently selected for applications involving exposure to acids or corrosive environments.

- Q: Can FRP pultrusion profiles be used in the telecommunications and data communication industry?

- Yes, FRP (Fiber Reinforced Plastic) pultrusion profiles can be used in the telecommunications and data communication industry. FRP pultruded profiles have several advantages that make them suitable for use in this industry. Firstly, FRP pultrusion profiles offer excellent electrical insulation properties, making them ideal for applications in the telecommunications and data communication industry where electrical conductivity needs to be minimized. FRP profiles do not conduct electricity, ensuring that there are no interference or grounding issues that could disrupt the transmission of data. Secondly, FRP pultrusion profiles are lightweight yet strong, providing a high strength-to-weight ratio. This makes them suitable for use in the construction of communication towers, antenna supports, and satellite dish mountings, where the profiles need to withstand wind loads and other environmental stresses. Additionally, FRP profiles have excellent corrosion resistance, which is crucial in the telecommunications and data communication industry where equipment is often exposed to harsh outdoor environments. Unlike traditional materials such as steel or aluminum, FRP profiles do not rust or corrode, ensuring the longevity and reliability of the infrastructure. Furthermore, FRP profiles can be easily customized and manufactured in various shapes and sizes to meet the specific requirements of telecommunications and data communication applications. This flexibility allows for the design and construction of complex structures that can accommodate different equipment and technologies. Overall, FRP pultrusion profiles offer a range of benefits that make them well-suited for use in the telecommunications and data communication industry. Their electrical insulation properties, lightweight yet strong nature, corrosion resistance, and flexibility in design make them a reliable choice for supporting infrastructure in this sector.

- Q: What are the features of Glass Fiber Reinforced Plastic Pultruded materials and chairs?

- Glass reinforced plastic extruded section bar has the characteristics of unlimited length, high utilization rate of raw material, corrosion resistance, good weatherability and long service life

- Q: What are the typical lifespan of FRP pultrusion profiles?

- The lifespan of FRP pultrusion profiles can vary depending on factors including material quality, environmental conditions, and specific application. On average, these profiles last 25 to 30 years. FRP pultrusion profiles are renowned for their durability and resistance to corrosion, rot, and UV radiation, which contributes to their extended lifespan. The use of top-notch resins and fibers during manufacturing ensures their ability to withstand harsh conditions and maintain structural integrity over time. It's worth mentioning that proper installation, regular maintenance, and adherence to usage guidelines can further increase the lifespan of FRP pultrusion profiles. Additionally, exposure to extreme temperatures, chemicals, and mechanical stress can impact their longevity. In summary, FRP pultrusion profiles provide a reliable and long-lasting solution for various applications in industries like construction, infrastructure, transportation, and marine.

Send your message to us

FRP Pultrusion Profiles:Latest Styles Anti-Ageing High-Quality FRP Pultruded Grating with Competitive Prices

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 300000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords