Composite Pipes FRP Grille, Non-Conductive FRP Fiberglass Decorative Window Grille

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 5000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of FRP Grille Description

Pultrusion moves the non-metal windows/doors to a new range of performance. Fibreglass/Polyester Resin Pultrusion form frame and parts, components and spacer bars in a new generation of thermally efficient, dimensionally stable.

2. Main Features of FRP Grille

1) Light weight, high strength - easier to transport and install with standard tools

2) Corrosion resistant - won’t rot or rust and absorbs minimal moisture

3) Chemical resistant - mild acid-alkali proof

4) Humidity resistant - no shrinking or swelling

5) Impact resistant - fiberglass mat distributes the load to prevent surface damage

6) Safety - won’t conduct electricity, and non-slip surfaces are available

7) Long-lasting - lower lifetime cost than traditional building materials

8) Low thermal conductivity - does not easily conduct heat or cold

9) Non-electrical conductivity, with non magnetic property

3. FRP Grille Images

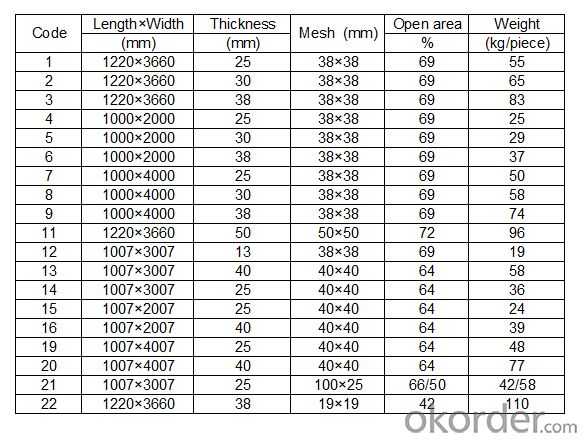

4. FRP Grille Specification

5. FAQ of FRP Grille

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

One of the leading manufacturers and suppliers specializing in FRP products in China. The integrated sales & service ensures customers with various demands an easier access for purchasing management.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible.

- Q: Designed to support FRP pipes, is it m or mm?

- Glass fiber reinforced plastic cable protection tube chemical composition: GRP winding pipe is a kind of glass fiber reinforced plastic product. With the continuous development of glass fiber reinforced plastic molding technology, FRP products have been widely used in various fields. FRP products have the advantages of light quality, high strength, corrosion resistance, long service life, flame retardant, high temperature resistance and various forms of products. Therefore, the industry gradually increase the use of glass fiber reinforced plastic products, which will be reinforced FRP mechanical properties and molding process put forward higher requirements. The forming process of FRP determines its shape, property and application prospect. The mechanical properties of glass fiber reinforced plastics determine whether their products can be widely used in industries with higher mechanical properties. Fiberglass reinforced plastic square tubes can replace some metal pipes used in industrial and civil fields, such as central air conditioning, chemical plants, etc. but glass fiber reinforced plastic square tube products are not common in the market. This is mainly due to the existence of poor strength, easy deformation and other defects.

- Q: What are the differences between inorganic FRP pipes and plexiglass pipes, what are the advantages and disadvantages?

- The inorganic glass fibre reinforced plastic wind pipe is made of unsaturated resin, and the organic is made of vinyl resin, which is strong and bears strong corrosion resistance

- Q: FRP duct material plan is how to mention?

- Multi plan square, but also according to the combination of site and construction drawings, to see how much

- Q: FRP pipe and 0.7 thick galvanized pipe which cost is low?

- Glass steel pipeline, FRP pipe and 0.7 galvanized steel pipe glass steel pipes cost is obviously low, FRP pipe material factory manufacturing costs and labor costs are relatively low, the price is only about the same thickness of galvanized pipe 60-70%, I hope you can help!

- Q: Glass fiber reinforced plastic GRE pipe broken hole how to repair and repair?

- Resin selection of good points, the general also line, as well as accelerators, curing agents, high-quality glass fiber cloth.

- Q: CGCT what's the meaning of the GRP sand pipe?

- If the thickness of the pipe can meet the requirements of pressure, but can not meet the stiffness requirement, will choose to increase the thickness of sand to meet the stiffness (of course can not directly increase the sand thickness to meet the requirement of stiffness, but the cost is too high). Sand sandwiched glass fiber reinforced plastic pipes only have more than one sand sandwiched with glass fiber reinforced plastic pipes, and sand layer can be understood to replace glass fiber with quartz sand. The sand pipe with the same thickness is compared with the glass fiber reinforced plastic pipe, but the sand holding pipe is cheap, but the strength is poor; and the glass steel pipe is opposite.

- Q: Where are the advantages of FRP pipes? Long life?

- AntifoulingThe pipe surface using unsaturated polyester resin, so the surface is clean and smooth, not by sea or sewage in a shell, fungi and other microbial contamination of borers, so increasing roughness, reduce cross section, increase maintenance costs. No such pollution, long-term use clean as before.

- Q: The outer thermal protection layer of the pipeline is made of GFRP. Which guy knows the construction method?

- The basic thing is to finish the heat preservation. Soak the PP cloth soaked in the solution and finish it. Then brush it one or two times. The key is to make the solution, with water heating method, or else not. If you want to strengthen the strength, you can finish the insulation, and then wrapped a layer of 10---20 purpose wire mesh, and then made glass fiber reinforced plastic

- Q: How can I make up the broken glass fiber?

- Don't let the powder go. It is autumn, the temperature is low, so to put more than summer curing agent, as to the exact proportion, I just guess should be: curing agent, accelerator, resin; 1:1.5:8 with glass fiber wrapped around the pipe, coated on the glass fiber cloth to make glass steel with good quickly, let the glass steel the glass fiber cloth fully soaked, waiting for the full glass steel after curing, and then repeated several layers. It will be strong.

- Q: What are the specifications of glass fibre reinforced plastic cable pipes? What are they?

- FRP cable pipe is a new type of composite material, it formed with resin as matrix and glass fiber reinforced composite materials, and unsaturated resin bonded molding and high quality cable protection is matched with the modern cable engineering construction with catheter products. Strong pressure resistance, light weight, smooth inner wall and small friction coefficient. It is easy to use the cable and does not damage the cable. Moving and transporting are easier and more convenient than metal pipe and concrete pipe. Construction and installation are simple and convenient and save labour.

Send your message to us

Composite Pipes FRP Grille, Non-Conductive FRP Fiberglass Decorative Window Grille

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 5000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords