FRP Pultrusion Profiles for Pollution Discharge Construction Grating

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

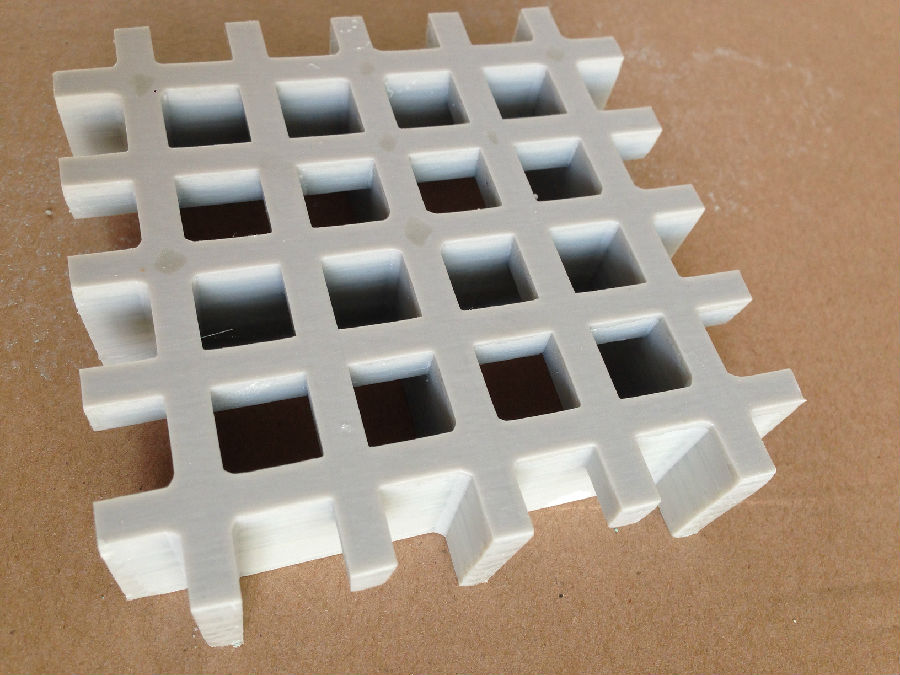

Specifications of FRP grating

- Meet ASTM E-84 AND ISO9001

- Anti-corrosion floor

- Anti-conductive

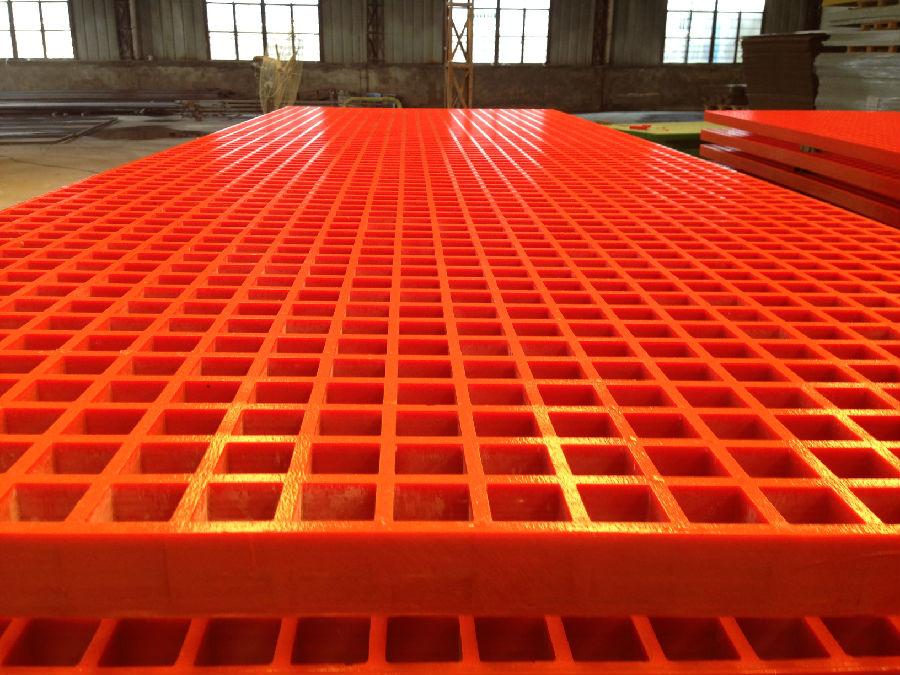

- Walkway,platform,trench cover,fence,stair treads

- Surface treatment

- Concave,grit,smooth,covered

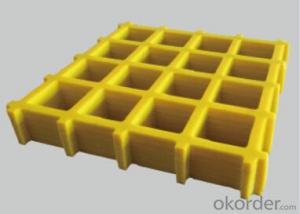

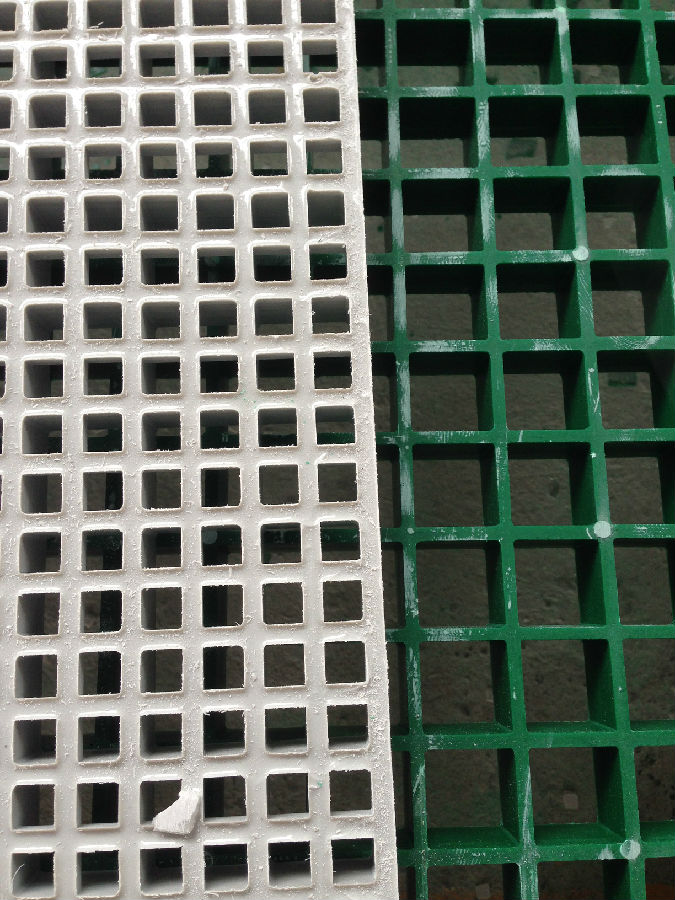

- Many colors can be chose: Red,yellow,grey,blue and other RAL colors

Common product specifications:

L×W×H(mm×mm×mm) | Center Distance(mm×mm) | Tendons relief(mm) | Module(mm) |

1220×3660×38 | 38.1×38.1 | 7 | 38.5-41 |

1220×3660×30 | 38.1×38.1 | 7 | 30.5-32 |

1220×3660×25 | 38.1×38.1 | 6.8 | 25.5-27 |

1220×3660×50 | 50.7×50.7 | 7.5 | 50.5-52 |

1000×4038×38 | 38.1×38.1 | 7 | 38.5-41 |

1000×4038×25 | 38.1×38.1 | 6.8 | 25.5-27 |

Features of FRP Grating:

- Corrosion and Chemical resistant

- Slip-resistant

- High strength-to-weight ratio

- Ergonomic

- Low maintenance

- Fire retardant

- Easily fabricated and installed

Other positive features:

Electrically and thermally non-conductive

Ultra-violet resistant

Provided in a number of grating thickness and panel sizes with many types of mesh size

Offers bi-directional strength characteristic

Impact resistance

Electronically transparent

As FRP grating has so many excellent features,so now FRP grating are widely used in many fields.

Drilling platform,walkway,water treatment plant,car wash and so on.

- Q: How do FRP pultrusion profiles perform in electrical grounding systems?

- FRP (Fiber Reinforced Polymer) pultrusion profiles have shown promising performance in electrical grounding systems. These profiles are made of a combination of fibers, such as glass or carbon, and a polymer resin matrix, which provides high strength, durability, and corrosion resistance. One of the key advantages of FRP pultrusion profiles in electrical grounding systems is their excellent electrical insulation properties. Unlike metals, which conduct electricity, FRP profiles have a very high resistance to electrical current, making them ideal for applications where electrical isolation is crucial. This property helps prevent the risk of electrical shock hazards and reduces the potential for short circuits. Additionally, FRP pultrusion profiles offer high mechanical strength while being lightweight. This makes them easy to handle and install, reducing labor costs and time. The profiles are also resistant to UV radiation, chemicals, and moisture, ensuring long-term performance and durability in various environmental conditions. Another benefit of FRP pultrusion profiles is their resistance to corrosion. Unlike metals, which can rust and deteriorate over time, FRP profiles are immune to corrosion, making them ideal for use in harsh or corrosive environments. This corrosion resistance ensures the longevity and reliability of the electrical grounding system. Furthermore, FRP pultrusion profiles are non-magnetic, which is advantageous in applications where magnetic interference needs to be minimized or eliminated. This characteristic prevents any interference with sensitive electrical equipment and ensures accurate electrical measurements. Overall, FRP pultrusion profiles offer a range of advantages in electrical grounding systems. Their excellent electrical insulation properties, high mechanical strength, corrosion resistance, lightweight nature, and non-magnetic characteristics make them a reliable and efficient choice for ensuring safe and reliable electrical grounding.

- Q: Are FRP pultrusion profiles resistant to oils and greases?

- Yes, FRP pultrusion profiles are generally resistant to oils and greases. This is because they are made from a combination of fiberglass and resin materials, which have inherent resistance to many chemicals including oils and greases. The resin used in the pultrusion process is typically a thermosetting resin, such as polyester or vinyl ester, which provides excellent resistance to chemical attack. Additionally, the fiberglass reinforcement adds strength and durability to the profiles, making them suitable for applications where exposure to oils and greases is expected. However, it is important to note that the specific resistance to oils and greases may vary depending on the type of resin and the specific chemical composition of the oils or greases. Therefore, it is recommended to consult the manufacturer or supplier for detailed information on the compatibility of FRP pultrusion profiles with specific oils and greases.

- Q: Are FRP pultrusion profiles resistant to jet fuel?

- Yes, FRP pultrusion profiles are generally resistant to jet fuel.

- Q: Can FRP pultrusion profiles be used in the telecommunications and data communication industry?

- Indeed, the telecommunications and data communication industry can utilize FRP (Fiber Reinforced Plastic) pultrusion profiles. These profiles possess numerous advantages that render them appropriate for incorporation in this particular sector. First and foremost, FRP pultrusion profiles exhibit exceptional electrical insulation properties, rendering them perfect for applications in the telecommunications and data communication industry where minimizing electrical conductivity is imperative. FRP profiles do not conduct electricity, thereby ensuring the absence of interference or grounding issues that could potentially disrupt data transmission. Secondly, FRP pultrusion profiles are both lightweight and robust, resulting in a high strength-to-weight ratio. This characteristic makes them well-suited for the construction of communication towers, antenna supports, and satellite dish mountings. In these applications, the profiles must withstand environmental stresses such as wind loads. Moreover, FRP profiles exhibit outstanding corrosion resistance, a crucial attribute in the telecommunications and data communication industry where equipment is frequently exposed to harsh outdoor environments. Unlike traditional materials like steel or aluminum, FRP profiles do not rust or corrode, thereby guaranteeing the longevity and reliability of the infrastructure. Furthermore, FRP profiles can be easily customized and manufactured in various shapes and sizes to meet the precise requirements of telecommunications and data communication applications. This flexibility enables the design and construction of intricate structures capable of accommodating different equipment and technologies. In summary, FRP pultrusion profiles provide a multitude of advantages that render them highly suitable for application in the telecommunications and data communication industry. Their electrical insulation properties, lightweight yet strong nature, corrosion resistance, and design flexibility make them a dependable choice for supporting infrastructure in this sector.

- Q: Can FRP pultrusion profiles be used in the construction of wind turbine blades?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in the construction of wind turbine blades. FRP pultrusion profiles offer several advantages that make them suitable for wind turbine blade construction. Firstly, FRP pultrusion profiles are lightweight yet strong, which is an important characteristic in wind turbine blades as they need to be able to withstand the aerodynamic forces exerted by the wind. The high strength-to-weight ratio of FRP pultrusion profiles allows for the construction of longer and more efficient blades. Additionally, FRP pultrusion profiles have excellent corrosion resistance properties, which is crucial for wind turbines exposed to harsh weather conditions. Unlike traditional materials like steel, FRP does not corrode, ensuring a longer service life for the wind turbine blades. Moreover, FRP pultrusion profiles can be customized to meet specific design requirements. This flexibility allows for the optimization of blade performance by tailoring the shape, thickness, and stiffness of the profiles to maximize energy capture and minimize fatigue. Furthermore, FRP pultrusion profiles offer good fatigue resistance, meaning they can withstand repeated loading cycles without experiencing significant degradation in performance. This is essential for wind turbine blades that are subjected to cyclic loading due to wind gusts and changes in wind direction. Finally, FRP pultrusion profiles are also electrically non-conductive, which is advantageous for wind turbine blades as it eliminates the risk of electrical discharge during operation. Overall, the lightweight, strong, corrosion-resistant, and customizable nature of FRP pultrusion profiles make them an excellent choice for the construction of wind turbine blades, contributing to the development of more efficient and durable wind energy systems.

- Q: Are FRP pultrusion profiles resistant to mold and mildew?

- FRP pultrusion profiles are known for their ability to resist mold and mildew. Made from a composite material consisting of a reinforced polymer matrix with fibers, usually glass fibers, FRP is unlike organic materials like wood or traditional plastics because it does not create a suitable environment for mold and mildew to thrive. The properties inherent in FRP, such as its non-porous nature and resistance to moisture absorption, contribute to its exceptional resistance to mold and mildew. Moreover, FRP pultrusion profiles are often manufactured with a smooth and glossy surface, further discouraging the growth of mold and mildew. In addition, FRP is chemically inert, meaning it does not react with most substances. This quality makes FRP profiles highly resistant to chemical attacks that could promote the growth of mold and mildew. Consequently, FRP pultrusions are frequently utilized in environments with high moisture and humidity levels, including bathrooms, swimming pools, and outdoor applications. Nevertheless, it is crucial to recognize that while FRP is resistant to mold and mildew, it is not entirely impervious. In extreme conditions where moisture levels remain consistently high and proper maintenance is neglected, there is still a possibility of mold and mildew growth. To ensure the longevity and resistance of FRP pultrusion profiles to mold and mildew, regular cleaning and maintenance are recommended.

- Q: Can FRP pultrusion profiles be used in pedestrian bridges?

- FRP pultrusion profiles can indeed be utilized in pedestrian bridges. They possess several advantages that render them appropriate for bridge construction, including their exceptional strength-to-weight ratio, resistance to corrosion, and durability. These profiles are manufactured by pulling continuous fibers through a resin bath and subsequently through a heated die, yielding a material that is both robust and lightweight. The lightweight nature of FRP pultrusion profiles makes them an ideal choice for pedestrian bridges, as they can be easily transported and installed. Furthermore, their high strength enables them to withstand the load requirements imposed by pedestrian traffic. Moreover, these profiles exhibit exceptional resistance to corrosion, which is particularly crucial for bridges that are exposed to environmental elements such as rain, humidity, and saltwater. In addition, FRP pultrusion profiles are highly durable and necessitate minimal maintenance in comparison to traditional construction materials like steel or concrete. They are impervious to rust or rot, and their non-conductive properties guarantee their safety when employed in areas with electrical infrastructure. To summarize, FRP pultrusion profiles present a suitable option for pedestrian bridges due to their lightweight nature, high strength, resistance to corrosion, and durability. These profiles offer a cost-effective and long-lasting solution for bridge construction, ensuring the safety and convenience of pedestrians.

- Q: Can FRP pultrusion profiles be used in the construction of theme park rides?

- Theme park rides can indeed incorporate FRP (Fiber Reinforced Polymer) pultrusion profiles. These profiles possess various advantages that make them suitable for this purpose. First and foremost, FRP pultrusion profiles possess a combination of lightness and strength, rendering them ideal for constructing ride structures that must endure dynamic loads and forces. Their remarkable strength-to-weight ratio enables the creation of intricate, sizable structures capable of supporting the weight of riders and withstanding the forces generated during operation. Moreover, FRP pultrusion profiles exhibit corrosion resistance, a crucial characteristic for theme park rides frequently exposed to outdoor environments, including moisture, chemicals, and UV radiation. This corrosion resistance ensures the durability and safety of the ride structures throughout their lifespan, reducing the need for costly maintenance and repairs. Another advantage of FRP pultrusion profiles lies in their design flexibility. They can be easily shaped and sized to meet the unique requirements of theme park ride designs. This versatility allows for the creation of distinctive, visually appealing ride structures that enhance the overall experience for park visitors. Furthermore, FRP pultrusion profiles possess excellent electrical insulation properties, particularly valuable for rides involving electrical components or systems. This insulation effectively minimizes the risk of electrical hazards, ensuring the safety of riders and operators. In conclusion, FRP pultrusion profiles are an excellent choice for constructing theme park rides due to their lightweight nature, high strength, corrosion resistance, design flexibility, and electrical insulation properties. By incorporating these profiles, safe, durable, and visually captivating ride structures can be developed, enhancing the enjoyment and excitement of theme park visitors.

- Q: Are FRP pultrusion profiles resistant to automotive fluids?

- FRP pultrusion profiles, commonly known as Fiber Reinforced Polymer profiles, possess a general resistance to automotive fluids. FRP, an abbreviation for Fiber Reinforced Polymer, is a composite material comprising a combination of fibers and a polymer matrix. The fibers utilized in FRP, such as fiberglass, carbon, or aramid, exhibit exceptional resistance to various automotive fluids, including oils, fuels, and coolants. The polymer matrix found in FRP profiles usually consists of a thermosetting resin, namely polyester, vinyl ester, or epoxy. These resins are renowned for their chemical resistance properties, which contribute to the high resistance of FRP pultrusion profiles towards a wide array of automotive fluids. They can endure exposure to different fluids without significant deterioration or loss of mechanical properties. It is important to acknowledge that the specific resistance of FRP pultrusion profiles to automotive fluids may differ based on the resin type and the composite material's precise composition. As a result, it is advisable to consult the manufacturer or supplier of the FRP profiles to verify their suitability for the intended application and the specific automotive fluids they may encounter.

- Q: Can FRP pultrusion profiles be used in the construction of conveyor systems?

- Yes, FRP (Fiber Reinforced Plastic) pultrusion profiles can be used in the construction of conveyor systems. FRP profiles offer several advantages such as high strength, lightweight, corrosion resistance, and durability, which make them suitable for conveyor applications. Additionally, FRP profiles can be easily customized to meet specific requirements, making them a versatile choice for conveyor system construction.

Send your message to us

FRP Pultrusion Profiles for Pollution Discharge Construction Grating

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords