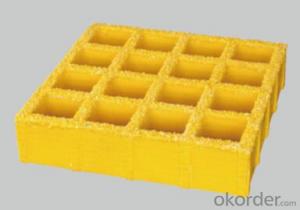

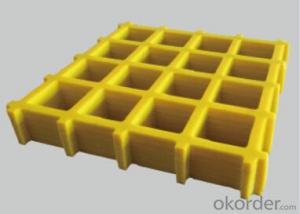

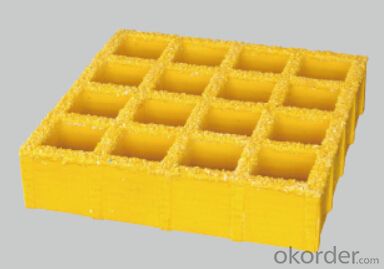

FRP Pultrusion Profiles for Gratings - Superior Slip Resistance for Sewage Plant Paving

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 8000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification:

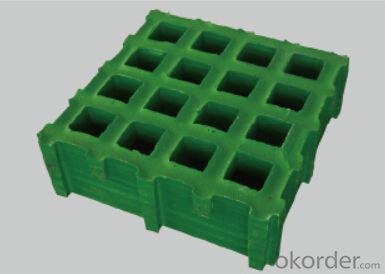

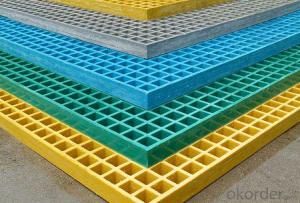

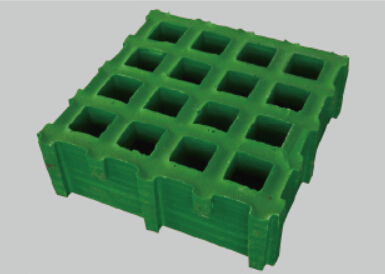

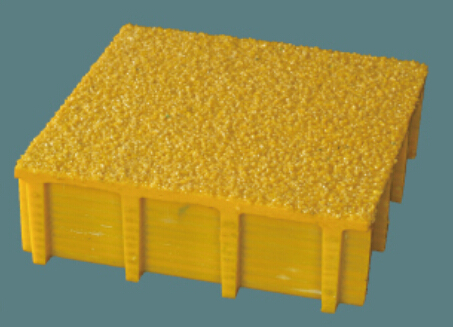

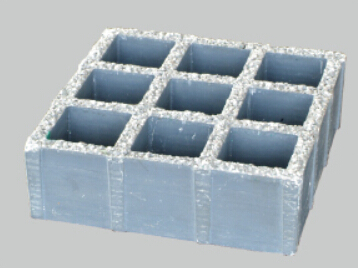

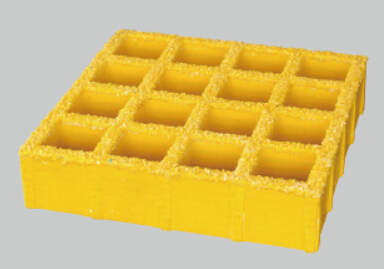

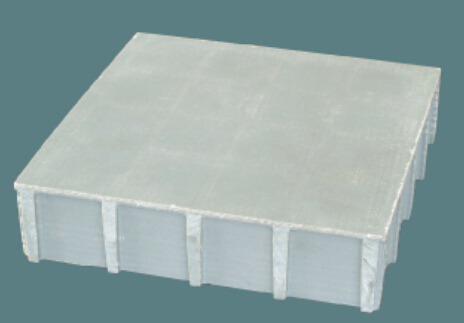

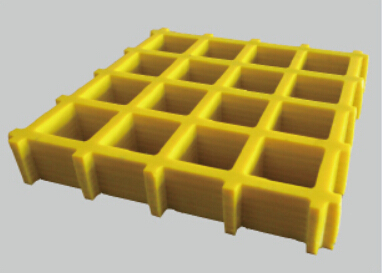

FRP molded grating made of vertical and horizontal continuous fiberglass fully soaked in unsaturated polyester resin giving perfect bi-directional mechanical properties. Combining unmatched corrosion resistance with strength, long life and safety, molded grating provide the ultimate in reliable performance, even in the most demanding corrosive conditions. Besides, it is easy to cut and install. CNBM offer the widest selection with panel sizes, colors and slip resistant surfaces, clients can avail FRP grating your specific requirements.

Product Features:

- Light but high loaded strength

- High anti-corrosion and anti-aging

- Easy installation and maintenance

- Low maintenance

- Non-conductive

- Lowest in life cycle cost

- Corrosion Resstance

- Anti-slippery

- Various sizes and color available

Colour Design:

To satisfy customer's design project, CNBM grating offers a wide selection of grating colors to choose from. The standard colors available for fiberglass grating as following:

- Blue

- Red

- Yellow

- Green

- Light Grey

- Dark Grey

Custom colors of fiberglass grating may be available upon request, you can contact us learn more.

- Q: How do FRP pultrusion profiles perform in extreme heat temperatures?

- FRP pultrusion profiles perform exceptionally well in extreme heat temperatures. Thanks to their advanced composition of fiberglass reinforced polymer, they possess high resistance to heat and can withstand temperatures well above 200°C without losing their structural integrity or mechanical properties. This makes FRP pultrusion profiles a reliable choice for applications where exposure to extreme heat is a concern.

- Q: Can FRP pultrusion profiles be used in telecommunications applications?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in telecommunications applications. FRP pultrusion profiles offer several advantages that make them suitable for telecommunications infrastructure. Firstly, FRP pultrusion profiles are lightweight yet strong, which makes them ideal for applications such as antenna supports, cable trays, and equipment racks. Their high strength-to-weight ratio allows for easier installation and transportation, while still providing the necessary structural support. Secondly, FRP pultrusion profiles are corrosion resistant, which is a crucial characteristic in telecommunication applications. Telecommunications infrastructure is often exposed to harsh environments, including moisture, chemicals, and extreme temperatures. Unlike traditional materials like steel or wood, FRP does not corrode or degrade in these conditions, ensuring long-term durability and reliability. Additionally, FRP pultrusion profiles offer electrical insulation properties, which is vital in telecommunications applications. They do not conduct electricity, making them safe for use in areas where electrical equipment is installed. This feature helps prevent electrical interference and ensures the integrity of the telecommunication system. Furthermore, FRP pultrusion profiles can be customized to meet specific design requirements. They can be manufactured in various shapes and sizes, allowing for flexibility in designing telecommunication infrastructure. This versatility makes FRP pultrusion profiles suitable for a wide range of applications within the telecommunications industry. In conclusion, FRP pultrusion profiles are well-suited for telecommunications applications due to their lightweight yet strong nature, corrosion resistance, electrical insulation properties, and customization possibilities. These attributes make them a reliable choice for supporting and protecting telecommunication infrastructure.

- Q: Can FRP pultrusion profiles be used in the production of electrical insulators?

- Indeed, FRP pultrusion profiles have the potential to be utilized in the manufacturing of electrical insulators. These profiles are renowned for their exceptional electrical insulation characteristics, rendering them appropriate for a wide array of electrical applications. The non-conductive and high-strength attributes of FRP materials make them an ideal choice for insulating components within electrical systems, including insulators. The creation of FRP pultrusion profiles entails saturating continuous fibers like fiberglass, carbon fiber, or aramid with a polymer resin, which is subsequently solidified and shaped through the pultrusion process. This process yields a resilient and lightweight material that exhibits remarkable electrical insulation properties. Electrical insulators serve the purpose of obstructing the flow of electric current between conductive materials or components. They are indispensable in electrical systems as they ensure safety and prevent electrical leakage or short circuits. FRP pultrusion profiles can be tailored and manufactured to meet the specific requisites of electrical insulators, encompassing dimensional accuracy, mechanical strength, and electrical insulation performance. Moreover, FRP pultrusion profiles offer numerous advantages when compared to conventional materials such as wood, porcelain, or ceramics. They possess corrosion resistance, possess a high strength-to-weight ratio, and can be easily customized to fulfill the specific demands of electrical insulator applications. Furthermore, FRP pultrusion profiles are non-conductive, a pivotal factor for electrical insulation. In summary, owing to their exceptional electrical insulation properties, durability, lightweight nature, and customization possibilities, FRP pultrusion profiles are exceedingly suitable for the production of electrical insulators.

- Q: Are FRP pultrusion profiles resistant to impact and vibration?

- Yes, FRP pultrusion profiles are generally resistant to impact and vibration due to their high strength-to-weight ratio and excellent flexural properties. The composite material used in the pultrusion process provides inherent toughness and durability, making FRP profiles suitable for applications where impact and vibration resistance are important considerations.

- Q: What is the torsional strength of FRP pultrusion profiles?

- The torsional strength of FRP (Fiber Reinforced Polymer) pultrusion profiles is determined by various factors including the type and arrangement of fibers, resin matrix, manufacturing process, and the overall design of the profile. FRP pultrusion profiles are typically designed to have high torsional strength due to the inherent properties of the composite materials used. The torsional strength of FRP pultrusion profiles can vary depending on the specific application and the desired performance requirements. Manufacturers often conduct extensive testing to determine the torsional strength of their profiles and provide relevant data to customers. FRP pultrusion profiles are known for their excellent torsional strength compared to traditional materials like steel or aluminum. The combination of high-strength fibers and a durable resin matrix allows FRP profiles to withstand significant torsional forces without experiencing permanent deformation or failure. It is important to note that the torsional strength of FRP pultrusion profiles can be customized to meet specific project requirements. By adjusting the fiber type, fiber orientation, resin system, and profile geometry, manufacturers can optimize the torsional strength to ensure that the profiles can withstand the anticipated loads and operational conditions. In summary, the torsional strength of FRP pultrusion profiles is generally high due to the unique properties of the composite materials used and can be further customized to meet specific application requirements.

- Q: Are FRP pultrusion profiles resistant to termites or other pests?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are inherently resistant to termites and other pests. Unlike traditional wood or metal materials, FRP profiles do not provide a food source for termites or any other pests. FRP is composed of a combination of reinforced fibers and a polymer matrix, typically made of fiberglass and resin. These materials are not appealing to pests and do not provide any nutritional value, making FRP profiles highly resistant to termite damage or infestation. This resistance to pests is one of the many advantages of using FRP pultrusion profiles in various applications, especially in outdoor or humid environments where termites are commonly found.

- Q: Are FRP pultrusion profiles resistant to moisture or humidity?

- Yes, FRP pultrusion profiles are highly resistant to moisture and humidity. The combination of fiberglass reinforcement and resin matrix used in their construction makes them non-corrosive and impervious to water absorption. This inherent resistance ensures their durability and performance in humid or moist environments without compromising their structural integrity.

- Q: Are FRP pultrusion profiles resistant to jet fuel?

- Yes, FRP pultrusion profiles are generally resistant to jet fuel.

- Q: Can FRP pultrusion profiles be used in the construction of wind turbine blades?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in the construction of wind turbine blades. FRP pultrusion profiles offer several advantages that make them suitable for wind turbine blade construction. Firstly, FRP pultrusion profiles are lightweight yet strong, which is an important characteristic in wind turbine blades as they need to be able to withstand the aerodynamic forces exerted by the wind. The high strength-to-weight ratio of FRP pultrusion profiles allows for the construction of longer and more efficient blades. Additionally, FRP pultrusion profiles have excellent corrosion resistance properties, which is crucial for wind turbines exposed to harsh weather conditions. Unlike traditional materials like steel, FRP does not corrode, ensuring a longer service life for the wind turbine blades. Moreover, FRP pultrusion profiles can be customized to meet specific design requirements. This flexibility allows for the optimization of blade performance by tailoring the shape, thickness, and stiffness of the profiles to maximize energy capture and minimize fatigue. Furthermore, FRP pultrusion profiles offer good fatigue resistance, meaning they can withstand repeated loading cycles without experiencing significant degradation in performance. This is essential for wind turbine blades that are subjected to cyclic loading due to wind gusts and changes in wind direction. Finally, FRP pultrusion profiles are also electrically non-conductive, which is advantageous for wind turbine blades as it eliminates the risk of electrical discharge during operation. Overall, the lightweight, strong, corrosion-resistant, and customizable nature of FRP pultrusion profiles make them an excellent choice for the construction of wind turbine blades, contributing to the development of more efficient and durable wind energy systems.

- Q: Can FRP pultrusion profiles be used in the construction of theme park rides?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in the construction of theme park rides. FRP pultrusion profiles offer several advantages that make them suitable for this application. Firstly, FRP pultrusion profiles are lightweight yet strong, making them ideal for constructing ride structures that need to withstand dynamic loads and forces. Their high strength-to-weight ratio allows for the creation of large, complex structures that can support the weight of riders and withstand the forces generated during operation. Additionally, FRP pultrusion profiles are corrosion-resistant, which is crucial for theme park rides that are often exposed to outdoor environments, including moisture, chemicals, and UV radiation. This corrosion resistance ensures that the ride structures remain durable and safe over their lifespan, reducing the need for costly maintenance and repairs. Another advantage of FRP pultrusion profiles is their design flexibility. They can be easily molded into various shapes and sizes to meet the specific requirements of theme park ride designs. This versatility allows for the creation of unique and visually appealing ride structures that enhance the overall experience for park visitors. Furthermore, FRP pultrusion profiles offer excellent electrical insulation properties, which can be essential for rides that involve electrical components or systems. This insulation helps to minimize the risk of electrical hazards and ensures the safety of riders and operators. In conclusion, FRP pultrusion profiles are well-suited for the construction of theme park rides due to their lightweight, high strength, corrosion resistance, design flexibility, and electrical insulation properties. These profiles can contribute to the development of safe, durable, and visually appealing ride structures that enhance the enjoyment and excitement of theme park visitors.

Send your message to us

FRP Pultrusion Profiles for Gratings - Superior Slip Resistance for Sewage Plant Paving

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 8000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords