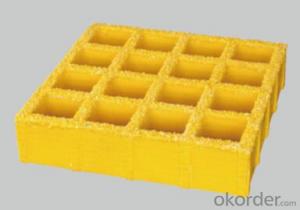

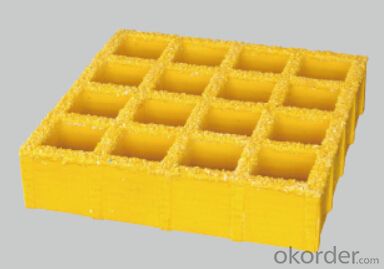

FRP Pultrusion Profiles Gratings - Superior Slip Resistance for Sewage Treatment Facilities

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 8000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification:

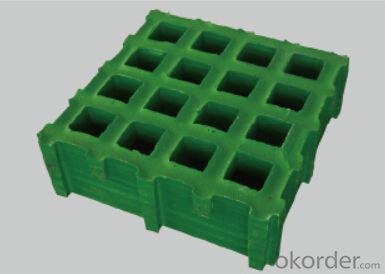

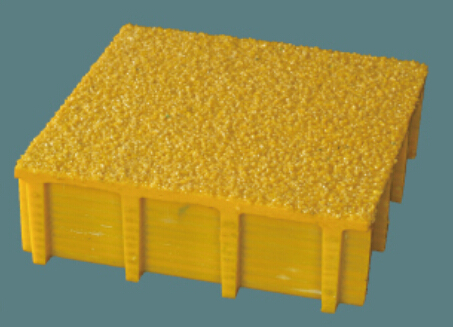

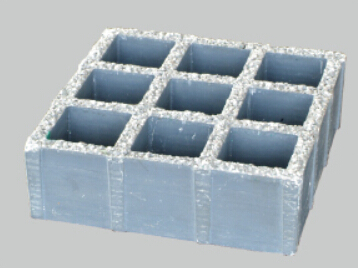

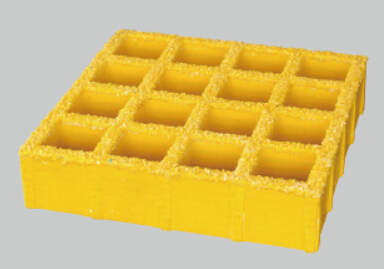

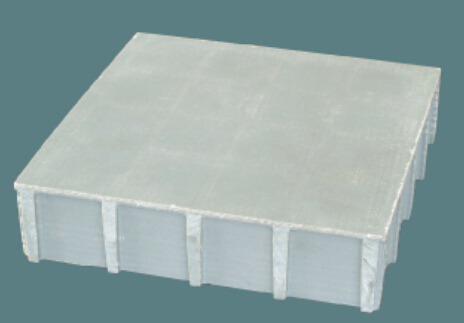

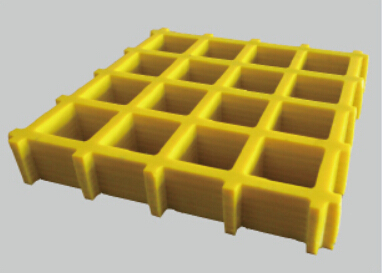

FRP molded grating made of vertical and horizontal continuous fiberglass fully soaked in unsaturated polyester resin giving perfect bi-directional mechanical properties. Combining unmatched corrosion resistance with strength, long life and safety, molded grating provide the ultimate in reliable performance, even in the most demanding corrosive conditions. Besides, it is easy to cut and install. CNBM offer the widest selection with panel sizes, colors and slip resistant surfaces, clients can avail FRP grating your specific requirements.

Product Features:

- Light but high loaded strength

- High anti-corrosion and anti-aging

- Easy installation and maintenance

- Low maintenance

- Non-conductive

- Lowest in life cycle cost

- Corrosion Resstance

- Anti-slippery

- Various sizes and color available

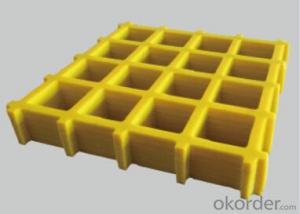

Colour Design:

To satisfy customer's design project, CNBM grating offers a wide selection of grating colors to choose from. The standard colors available for fiberglass grating as following:

- Blue

- Red

- Yellow

- Green

- Light Grey

- Dark Grey

Custom colors of fiberglass grating may be available upon request, you can contact us learn more.

- Q: What are the typical applications for FRP pultrusion profiles?

- FRP (Fiber Reinforced Plastic) pultrusion profiles find a wide range of applications across various industries. One of the most common uses is in the construction industry, where these profiles are used for structural components such as beams, columns, and platforms. They offer high strength-to-weight ratio, corrosion resistance, and durability, making them ideal for building infrastructure that requires long-lasting, low-maintenance solutions. In the transportation sector, FRP pultrusion profiles are used for manufacturing lightweight components like bus and truck bodies, railcar panels, and wind turbine blades. Their lightweight nature helps reduce fuel consumption and increase energy efficiency. Moreover, their resistance to chemicals, moisture, and UV radiation ensures their longevity even in harsh operating environments. In the electrical and power distribution field, FRP pultrusion profiles are utilized for manufacturing insulating supports, cable trays, and ladder racks. These profiles provide excellent electrical insulation properties, making them a safe and reliable choice for electrical installations. Additionally, their non-conductive nature helps prevent electrical accidents and eliminates the risk of electric shock. FRP pultrusion profiles also find applications in the marine industry, where their resistance to saltwater corrosion makes them suitable for manufacturing boat hulls, decks, and other marine components. Their high strength and stiffness make them capable of withstanding the harsh conditions of the marine environment. Furthermore, FRP pultrusion profiles are used in the chemical processing industry for manufacturing tanks, pipes, and platforms. Their resistance to various chemicals and corrosive substances ensures the integrity of the equipment and enhances safety in chemical plants. Overall, the typical applications for FRP pultrusion profiles span across industries such as construction, transportation, electrical, marine, and chemical processing. Their unique properties make them a versatile and reliable choice for various structural and functional applications.

- Q: Are FRP pultrusion profiles resistant to impact?

- FRP pultrusion profiles exhibit a general resistance to impact. The amalgamation of robust fibers and the polymer matrix employed during manufacturing renders FRP profiles exceptionally enduring, enabling them to endure substantial impacts without fracturing or shattering. Furthermore, the pultrusion process guarantees the uniform dispersion of fibers within the profile, thereby bolstering its capacity to resist impact. Consequently, FRP pultrusion profiles are ideally suited for impact-prone applications, including construction, transportation, and infrastructure ventures.

- Q: What is the compression strength of FRP pultrusion profiles?

- The compression strength of FRP pultrusion profiles can vary depending on the specific design and manufacturing process. However, on average, FRP pultrusion profiles typically exhibit compression strengths ranging from 20,000 to 40,000 pounds per square inch (psi).

- Q: Are FRP pultrusion profiles resistant to impact from flying debris?

- FRP pultrusion profiles possess notable strength and durability, earning them a reputation in the industry. Their inherent properties make them generally impervious to damage caused by flying debris. This exceptional impact resistance can be attributed to the combination of reinforcing fibers, often fiberglass, and the polymer matrix. The extent of resistance to flying debris impact may vary depending on the design, thickness, and composition of the FRP pultrusion profiles. Nevertheless, these profiles are typically engineered to withstand impact forces and effectively withstand damage from airborne debris. Moreover, FRP pultrusion profiles find extensive use in industries such as construction, transportation, and infrastructure, where impact resistance is of utmost importance. These profiles have undergone rigorous testing and have demonstrated their ability to endure various impact scenarios, making them a trustworthy choice for applications that involve the potential for flying debris. It is vital to recognize that although FRP pultrusion profiles boast commendable impact resistance, the severity of the impact and the speed of the flying debris can still impact the degree of damage incurred. Thus, it is advisable to consult with the manufacturer or an engineer to ensure the chosen FRP profile is suitable for the intended application and potential impact conditions.

- Q: Are FRP pultrusion profiles resistant to electrical surges or lightning strikes?

- FRP pultrusion profiles are inherently non-conductive materials, which means they do not conduct electricity. Therefore, they can provide some level of resistance to electrical surges or lightning strikes. However, it is important to note that the level of resistance may vary depending on the specific composition and thickness of the FRP profiles. In high-risk areas prone to lightning strikes, additional measures may be necessary to ensure proper protection against electrical surges.

- Q: Can FRP pultrusion profiles be used in the agricultural and farming industry?

- Yes, FRP pultrusion profiles can be used in the agricultural and farming industry. These profiles are lightweight, durable, and resistant to corrosion, making them suitable for various applications such as structural supports, fencing, gates, and equipment enclosures. They offer high strength-to-weight ratio, excellent weather resistance, and can withstand harsh environmental conditions commonly found in agricultural settings. Additionally, FRP profiles are non-conductive and have low thermal conductivity, which makes them ideal for electrical insulation and thermal management in farm equipment.

- Q: Can FRP pultrusion profiles be used in electrical insulation applications?

- Yes, FRP pultrusion profiles can be used in electrical insulation applications. FRP (Fiber Reinforced Polymer) materials have excellent electrical insulation properties, making them suitable for a wide range of electrical applications. The pultrusion process ensures that the profiles have uniform insulation properties and high strength, making them ideal for use in electrical insulation applications.

- Q: Are FRP pultrusion profiles resistant to chemicals used in pulp and paper mills?

- FRP (Fiber Reinforced Polymer) pultrusion profiles are known for their excellent resistance to chemicals, making them a suitable choice for various applications, including those in pulp and paper mills. These profiles are specifically engineered to withstand exposure to a wide range of chemicals commonly used in these industries. The chemical resistance of FRP pultrusion profiles can be attributed to the inherent properties of the composite materials used in their construction. Typically, these profiles are composed of a combination of resins (such as polyester or vinyl ester) and reinforcements (such as fiberglass or carbon fiber). This combination imparts high chemical resistance to the finished product. The resins used in FRP pultrusion profiles play a crucial role in determining their chemical resistance. Polyester resins, for instance, provide good resistance to a variety of chemicals, including acids, alkalis, and solvents. Vinyl ester resins, on the other hand, offer even greater chemical resistance, making them suitable for highly corrosive environments. Additionally, the reinforcement materials used in FRP pultrusion profiles, such as fiberglass or carbon fiber, further enhance their chemical resistance. These reinforcements act as a barrier, preventing chemical penetration and protecting the structural integrity of the profile. It is important to note that the specific chemical resistance of FRP pultrusion profiles can vary depending on the resin and reinforcement materials used. Therefore, it is essential to select profiles that are specifically designed and manufactured to withstand the chemicals commonly found in pulp and paper mills. Overall, FRP pultrusion profiles are indeed resistant to the chemicals used in pulp and paper mills. Their high chemical resistance, combined with other advantageous properties such as high strength-to-weight ratio and corrosion resistance, make them an ideal choice for these demanding industrial environments.

- Q: Are FRP pultrusion profiles resistant to electromagnetic interference?

- Yes, FRP pultrusion profiles are generally resistant to electromagnetic interference (EMI). The use of fiberglass reinforced plastic (FRP) in pultrusion profiles provides excellent electrical insulation properties, which help to minimize the effects of electromagnetic interference. Unlike metals, which are conductive and can easily transmit electrical signals, FRP materials have high dielectric strength and low electrical conductivity. This makes FRP pultrusion profiles less susceptible to EMI and allows them to act as barriers to electromagnetic waves. Additionally, FRP materials can be further enhanced with additional layers or coatings to increase their EMI shielding effectiveness if required. Overall, FRP pultrusion profiles are a reliable choice for applications where resistance to electromagnetic interference is important.

- Q: Can FRP pultrusion profiles be used in electrical insulation applications?

- FRP pultrusion profiles are capable of being utilized in electrical insulation applications. They possess exceptional electrical insulation properties, rendering them appropriate for a broad range of electrical applications. The superior dielectric strength of FRP materials ensures the efficient containment of electrical currents within designated pathways, thus preventing leakage and electrical hazards. Moreover, FRP profiles exhibit low electrical conductivity, thereby decreasing the likelihood of electrical shorts and enhancing overall safety in electrical insulation applications. The non-magnetic characteristics of FRP materials are also advantageous as they eliminate the potential for electromagnetic interference (EMI) in sensitive electrical systems. Furthermore, FRP pultrusion profiles are lightweight, resistant to corrosion, and boast a lengthy operational lifespan. This renders them an economical and robust solution for electrical insulation applications.

Send your message to us

FRP Pultrusion Profiles Gratings - Superior Slip Resistance for Sewage Treatment Facilities

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 8000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords