Food Grade mcpp Plastic Film Metallizing cpp Film of Food Package

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 100000000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Food Grade mcpp Plastic Film Metallizing cpp Film of Food Package

Quality: 100% virgin pet

HS Code: 777309664

Processing Type: Multiple extrusion

Thinckness: 8mic-12mic

Main size: Width≤2350mm

Length 18000m/9000m/6000m

Usage: 1)PET food grade packing film

2)PET printing film, pet release film

3)Metalized pet film,cpp/pet sealing film

4)Pet laminating film

Remark: All the indicators could be customized which includes the thickness, width, length, diameter.

Product Description

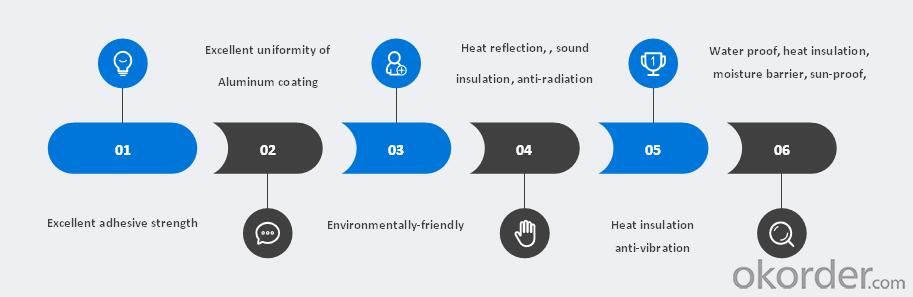

Metallized film (VMPET) is a silver color reflective film that is plated by aluminum layer on the film surface in vacuum condition which makes it high barrier resistance of oxygen and water vapor. It has glossy metallic appearance of an aluminum foil at a reduced weight and cost that can be widely used for packaging, decoration, insulation and electronics.

Our Advantage

Superiority of price: we control the whole process from raw materails purchasing to final product manufacturing.

Efficiency advantage: the fastest time of delivery is 7days.

Customization: all indicators could be customized which includes the thickness, width, length, diameter.

Usage

1) 12mic silver metalized PET film coated PE is used to laminated with EPE foam or Bubble as thermal Insulating materials, which could be used as underlay, wrap wall insulation materials,

2) To make sunshade or ice bag;

3) Used as emergency blanket, it can retains 80% percent of your radiant body heat

4) To make static shielding bag for electronic product

WorkPlace:

This is our metalized polyester pet film produce line,

you can visit our factory at anytime,

we asked workshop clean and tidy to ensure that the product with high quality and error-free.

Device Show

- Q: Can plastic film be printed?

- Plastic film can be printed, the current printing technology is already very mature, you can print 3D. Now there are plastic film printers.

- Q: Can the concrete surface be covered with plastic film in winter construction?

- The advantage of covering plastic films is that water conservation concrete. The need for this chemical reaction. The plastic film prevents water from evaporating while causing heat dissipation and achieves the effect of heat preservation.

- Q: What is film capacitor?

- According to the kind of plastic film is divided into: poly ether capacitor (also known as Mylar capacitor), polypropylene capacitor (also known as PP capacitor), polystyrene capacitor (also known as PS capacitor) and poly carbonate capacitor. The structure of capacitor and the same medium, polyester or polystyrene etc.. Polyester film capacitor has high dielectric constant, small volume, large capacity and good stability. It is suitable to be used as bypass capacitor. Polystyrene film capacitors, dielectric loss, high insulation resistance, but the temperature coefficient is large, can be used in high frequency circuits.

- Q: In a bowl with the seeds covered with plastic film, you need time off the air

- Plastic film cover in order to keep the soil moisture in the soil, air breathing for seed germination and growth of enough, only to grow seedlings, to remove the cover film, otherwise the film may have a high temperature.

- Q: Method for removing stainless steel plastic film

- Because of their environmental protection characteristics, many water-soluble films have attracted extensive attention in developed countries all over the world. Abroad are Japan, the United States and France etc. the production and sales of such products, such as the United States W.T.P company, C.C.L.P company, GRENSOL company in France and Japan synthetic chemical company and so on, the user is also some well-known large companies, such as Bayet (Bai Er), Henkel (Henkel), Shell (Shell) etc..

- Q: Masks that layer of white plastic film is used for what?

- That layer of plastic film should be removed when doing mask, it is to prevent the mask folded when the stick together and prevent loss of nutrients, to prevent mask deformation. Do not use with the mask, and if used together, will lead to loss of permeability of the mask, but will lose the role of the mask itself, it may also play a counter effect.

- Q: Can electrostatic generator adsorb plastic film?

- An electrostatic generator can be used to adsorb plastic films;ESD (electrostatic discharge generator) is mainly applied to the ESD test of human body metal model for system level electronic equipment, such as mobile phone and computer, including electrostatic generator and electrostatic discharge gun;

- Q: Why should plastic film be compounded? What are the composite soft packing substrates?

- Packaging made from a single kind of plastic film is not up to the mark. Such as heat sealing, load bearing, gas resistance, aeration, oxygen resistance, oil suppression, vacuum, cooking, anti leakage performance. Therefore, it is necessary to use several kinds of plastic film combinations with special functions to complement each other. The combination of several kinds of films requires adhesive processing, and the composite films are packed to meet the needs of the contents.

- Q: Does the plastic film on the bank card fall off and affect the use?

- The damage of the plastic film on the front of the bank card does not affect the use of the card. The key is the magnetic stripe on the back of the bank card. If the magnetic stripe is valid, your bank card can be used normally. It doesn't matter.

- Q: Plastic film surface corona treatment, the bigger the better?

- With our experience and Shun packaging, plastic film on the surface of the corona treatment is not better, if the surface treatment of plastic film spark is too large, will make the surface film breakdown, aging, luster faded, heat sealing performance of adhesion, strength reduction or inner film variation, is not easy to seal.

Send your message to us

Food Grade mcpp Plastic Film Metallizing cpp Film of Food Package

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 100000000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords