Metallized PP Tape for Consumer Electronics Metalizing

- Loading Port:

- Xingang Sea Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- USD3000.00 roll

- Supply Capability:

- 30 Days For 1x20' FCL roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification of Consumer Electronic Metalizing Bopp Tape

1. Consumer Electronic Metalizing Bopp Tapeis with silver color metallized BOPP film as carrier, coated with water acrylic adhesive.

2. Metallized BOPP tape is with similar application as that of aluminum foil tape. Mainly used in HVAC industry, such as joining & sealing flexible air duct seams & connections, and light reflection. Please note that metallized BOPP tape is not as good as aluminum foil tape in quality, but they are very competitive in price and they are not easy to tear than aluminum foil tape.

3. Standard cut roll packing: several rolls wrapped in polyfilm, then into cartons. We can also offer special packing as per customer's requirements, such as label, core printing and sticker.

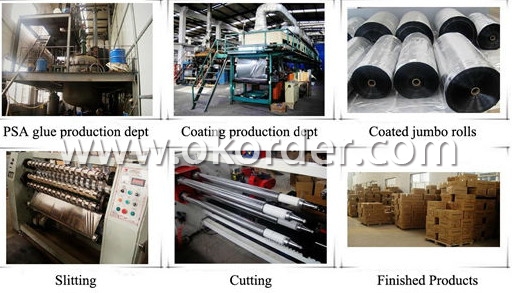

CONSTRUCTION Of Consumer Electronic Metalizing Bopp Tape:

Metalized OPP film: 20micron

Adhesive: Water acrylic

TYPICAL PHYSICAL PROPERTIES:

Total thickness (metalized opp + adhesive): 40 micron

Initial attack: ≥12﹟

180°Peel Adhesion: ≥29.17KN/M

Holding power: > 5h

Tensile strength: ≥23.6 Oz/in

Core I.D.: 3" (76mm)

Sizes of Log Roll: 1020mm x 50m, 1020mm x 100m,

Sizes of Jumbo Roll: 1020mm x 1000m, 1020mm x 500m

Based on order, special sizes and log rolls or jumbo rolls are also available.

Package of Consumer Electronic Metalizing Bopp Tape:

6 rolls wrapped with film. 72 rolls per carton

- Q: Does the BOPP sealing adhesive tape belong to the light textile industry?

- BOPP sealing tape belongs to the plastic packaging industry, because the use of BOPP film is plastic film

- Q: What's the price for BOPP sealing tape printing?

- Perhaps they can help you, I have made a lot of friends in it, and benefited a lot. I hope to adopt, I really help.

- Q: Can CPP film produce sealing tape?

- 3, (steaming film) CPP, good heat resistance. Because the softening point of PP is about 140 DEG C, this kind of film can be used in hot filling, retort bags, aseptic packaging and other fields. With acid, alkali, grease resistance, making it bread products, packaging or laminated materials and other fields of choice. Its contact with food safety, demonstration of good performance, will not affect the flavor of the built-in food, and can choose different grades of resin to obtain the desired characteristics.

- Q: We already know the kilogram price of BOPP tape semi-finished product. How do you calculate the price of square meter?. 1KG= is how many square meters, is not the thickness of the impact?

- You can use a volume, how much is it, the total amount divided by the width divided by the length is the square price

- Q: Is BOPP the same as OPP?

- 2>BOPP heat sealing filmUses: mainly used for printing, bag making, etc..3>BOPP cigarette packing filmPurpose: high speed cigarette packing.4>BOPP pearlescent filmUsage: used for printed food and daily necessities packing.5>BOPP metallized filmUses: used as a vacuum plated metal, radiation, anti-counterfeiting substrate, food packaging.

- Q: How can I remove the impression of the scotch tape from the fridge?

- The refrigerator door will have a layer of tape on it. It's for protection!

- Q: Two jobs do not know how to choose, BOPP tape foreign trade prospects, tangled in

- Since you care about the future, then choose what you want to do, want the future and don't want to risk it. What a good thing. Napoleon, a successful master, said: "success depends on 0 of the amount of problem you solve.".

- Q: I would like to open a transparent tape, that is, sealed tape factory. Read a lot of other people's questions, basically know there are two ways, one is to buy film and glue

- : used to cut paper tube with tape rewinding machine: 3 for textured paper, double-sided adhesive tape, 4 cutting machine: used to cut textured paper, double-sided adhesive tape type 5 small rewinding machine: used to do well in the complex side BOPP tape. If the worker speaks, 3-5 people can. (if you haven't done the industry, it's better not to choose the industry. Profit margins are too low.).

- Q: What's the tape for sealing tape?

- In order to obtain better comprehensive performance, the multilayer composite method is usually used in the process of production. BOPP can be combined with a variety of different materials to meet special application needs. Such as BOPP and LDPE (CPP), PE, PT, PO and PVA composite are highly resistance gas, humidity resistance, transparency, high and low temperature resistance, steam resistance and oil resistance, different composite membrane can be applied to oily food, delicious food, dry food, food, cooking cooked food, dipping MSG, pancakes, rice cake and other packaging.

- Q: How do you clean the glue on the scotch tape? 20, on the distribution of sincerity, seeking experts

- If you want to reclaim the tape, consider the safety, the price, and the toxicity. It's better to soak it with industrial alcohol and then hand brush it. It's also a waste of alcohol, otherwise it's too wasteful. I do not know how much alcohol you need, and if a few kilograms or dozens of kilograms, used up to do an alcohol stove, cook, burn, large amount, we must try to sell. Other solvents, such as acetone, butyl acetate and alcohol ethers (such as ethylene glycol, butyl ether, propylene glycol, methyl ether) can also be washed away

1. Manufacturer Overview

| Location | Shanghai, China |

| Year Established | 2007 |

| Annual Output Value | US$ 1 Million |

| Main Markets | 20.00% North America 20.00% South America 10.00% Eastern Europe 10.00% Southeast Asia 10.00% Northern Europe 10.00% South Asia 10.00% Western Europe 5.00% Africa 5.00% Mid East |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai, Port |

| Export Percentage | 30% - 50% |

| No.of Employees in Trade Department | 51-100 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 1000 M2 |

| No. of Production Lines | Above 3 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | High; Average |

Send your message to us

Metallized PP Tape for Consumer Electronics Metalizing

- Loading Port:

- Xingang Sea Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- USD3000.00 roll

- Supply Capability:

- 30 Days For 1x20' FCL roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords