8.79KG/M steel flat bar for construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering 8.79KG/M steel flat bar for construction at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

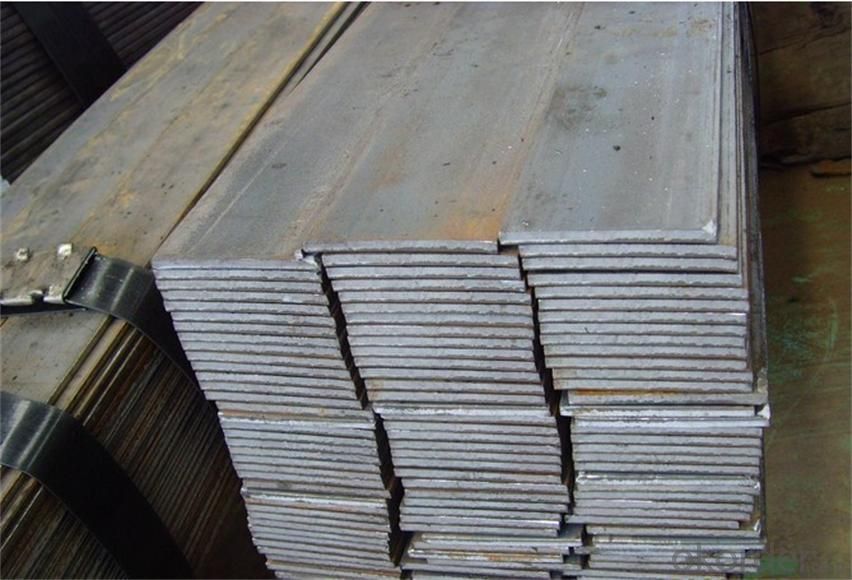

8.79KG/M steel flat bar are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Steel Flat Bar for construction are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Manufacture: slited

Slitting precision (width) : 0.5 mm or less

Raw material: Q235B, Q345B, Q235-1 b

crosscutting precision (length) : 2 mm or less

Processing: the thickness of 2.0-16 mm;

Shear length: 2000 mm above

Wide degree: 15-1250 - mm;

Leveling precision: 1-2 MM square

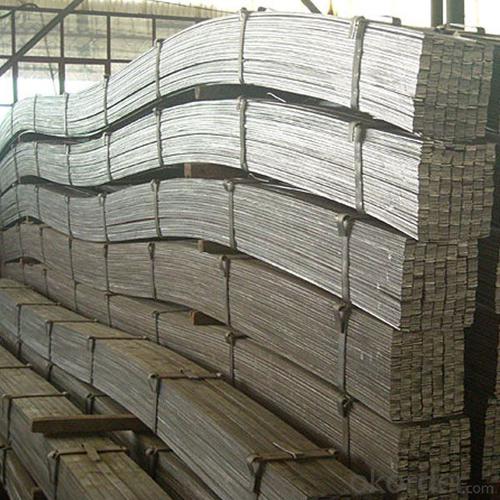

Packaging: Export packing, nude packing, bundled

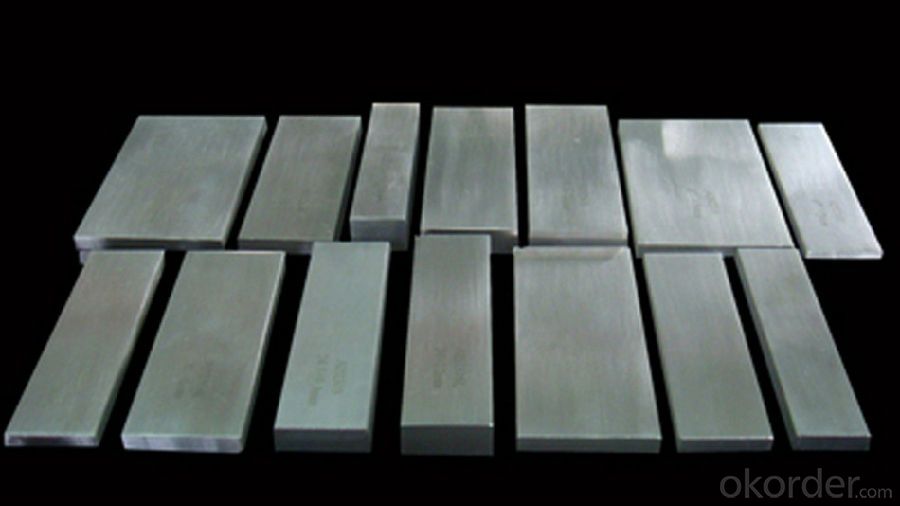

The Carbon Steel Flat Bar is made through three processes:

1.Feeding the material: Feeding the row material (the steel plate) to Slitting Line.

2.Slitting:The steel plate would be slitted into expected width by lengthways cutter.

3. Leveled and cutting: The plat bar would be ground into level by the grinder and then cut into required length.

FAQ:

Q1: How soon can we receive the product after purchase?

A1: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q2: What makes stainless steel stainless?

A2: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

- Q: How is the thickness of a steel flat bar measured?

- The thickness of a steel flat bar is typically measured using a caliper or a micrometer. These tools allow for precise measurement by closing their jaws around the bar and displaying the thickness on a scale or digital readout.

- Q: Can steel flat bars be used in the manufacturing of marine equipment?

- Certainly! Marine equipment can benefit from the use of steel flat bars. This versatile and strong material is frequently employed in the marine industry because of its exceptional durability and resistance to corrosion. When it comes to manufacturing marine equipment, steel flat bars can be utilized to create a variety of essential components, including frames, brackets, supports, and structural elements. The flat shape of these bars facilitates easy cutting, shaping, and welding, making them highly suitable for a wide range of applications in the marine industry. Moreover, to enhance their resistance to saltwater corrosion and guarantee their suitability for marine environments, steel flat bars can be treated with coatings or galvanized.

- Q: Can steel flat bars be used for manufacturing architectural facades or cladding?

- Architectural facades or cladding can be manufactured using steel flat bars, which are versatile and durable. Steel is a popular choice due to its strength and aesthetic appeal. These flat bars can be easily shaped and fabricated to meet specific design requirements, making them suitable for various architectural applications. There are several advantages to using steel flat bars for architectural facades or cladding. Firstly, steel offers excellent structural properties, providing stability and resistance against external forces like wind or seismic activity. This makes it a dependable option for buildings that require a strong and sturdy exterior. Furthermore, steel flat bars can be finished in different ways to enhance their visual appeal. They can be painted, powder coated, or left untreated for an industrial look. Steel's natural gray or metallic appearance can complement a wide range of architectural styles, from modern to traditional. Additionally, steel flat bars are highly resistant to corrosion and weathering, making them ideal for exterior applications. With proper maintenance, steel facades or cladding can withstand harsh weather conditions and maintain their appearance for many years. However, it is crucial to consider specific project requirements and consult with architects, engineers, and manufacturers to ensure that the chosen steel flat bars meet the necessary specifications and standards for architectural facades or cladding.

- Q: What is the weight calculation formula for galvanized flat steel and galvanized steel angles?

- (1) grounding wire is generally made of 40mm * 4mm galvanized flat steel.(2) galvanized steel or angle steel for earthing body. The diameter of the steel pipe is 50mm, the wall thickness of the pipe is not less than 3.5mm, and the length is 2 to 3m. Angle iron shall be 50mm * 50mm * 5mm.(3) the top of the grounding body from the ground 0.5 ~ 0.8m, in order to avoid thawing soil, soil resistivity or steel angle as the root number of the ground around the body and decide, generally not less than two, each spacing is 3 ~ 5m(4) the distance between the grounding body and the building is over 1.5m, and the distance between the grounding rod and the independent lightning rod is greater than 3m.(5) the connection of grounding wire and earthing body shall be done by lap welding.

- Q: What are the different standards for steel flat bars?

- Steel flat bars, also known as steel flats or simply flats, come in a variety of standards that dictate their size, shape, and composition. These standards are established to ensure uniformity and quality in the manufacturing and use of steel flat bars. One of the most widely recognized standards for steel flat bars is the ASTM A36, which sets the requirements for carbon structural steel. This standard specifies the chemical composition, mechanical properties, and dimensional tolerances for steel flats used in general structural purposes. Another commonly used standard is the ASTM A108, which covers carbon steel bars for general purpose applications. This standard classifies steel flat bars into different grades based on their chemical composition and mechanical properties. For more specialized applications, there are specific standards that cater to different industries. For instance, the ASTM A276 is a standard that applies to stainless steel bars and shapes. Within this standard, there are specific requirements for stainless steel flat bars, including their chemical composition, mechanical properties, and dimensions. In addition to ASTM standards, there are also international standards that govern the production and use of steel flat bars. The most prominent one is the EN 10058, which is a European standard that specifies the tolerances on dimensions and shape for hot-rolled steel flat bars. Furthermore, there are regional or national standards that may be applicable in certain countries. For example, the JIS G3194 is a Japanese industrial standard that provides specifications for hot-rolled steel flat bars used in general structures. These standards are essential to ensure the quality, compatibility, and interchangeability of steel flat bars in various applications. Manufacturers, engineers, and users rely on these standards to select and work with steel flat bars that meet their specific requirements and adhere to industry norms.

- Q: What are the different types of surface treatments available for steel flat bars?

- Steel flat bars have a variety of surface treatments available, each with its own unique benefits and characteristics. Some commonly used treatments include: 1. Hot-dip galvanizing: By immersing the steel flat bar in molten zinc, a protective layer is formed to prevent rust and corrosion. This treatment offers excellent durability and resistance to atmospheric conditions. 2. Powder coating: This method involves applying a powdered polymer coating to the surface of the steel flat bar. The powder is charged with electricity and then cured under heat, resulting in a tough and durable finish. Powder coating provides excellent resistance to impact, chemicals, and abrasion, and offers a wide range of colors and finishes. 3. Electroplating: Electroplating deposits a thin layer of metal onto the steel flat bar through an electrochemical process. The choice of metal, such as chromium, nickel, or zinc, depends on the desired properties. Electroplating enhances the appearance, corrosion resistance, and wear resistance of the steel. 4. Paint coating: Applying a paint coating to the steel flat bar is a commonly used surface treatment. This can be done through methods like spray painting or roller coating. Paint coatings not only provide a decorative finish but also protect against corrosion and environmental factors. 5. Anodizing: Although primarily used for aluminum, anodizing can also be applied to steel. This process involves creating a controlled oxidization layer on the metal's surface, enhancing corrosion resistance and providing an attractive finish. Anodizing can be done in various colors and offers excellent durability. 6. Phosphating: Phosphating treats the steel flat bar with a phosphate coating, typically by immersing it in a solution containing phosphoric acid and other chemicals. This creates a thin, crystalline layer that improves corrosion resistance and enhances the adhesion of subsequent coatings or paints. These examples represent just a few of the surface treatments available for steel flat bars. The choice of treatment depends on factors such as desired appearance, environmental conditions, and specific functional requirements.

- Q: Can steel flat bars be used as reinforcement in concrete structures?

- Certainly, reinforcement in concrete structures can be achieved by utilizing steel flat bars. In concrete construction, steel bars are widely employed to enhance the strength and durability of the structure. These bars are positioned within the concrete to counteract tensile forces and prevent the occurrence of cracks. When it comes to reinforcing beams, slabs, and other structural components, steel flat bars prove to be particularly advantageous as they significantly enhance the flexural strength of the concrete. Additionally, the flat shape of these bars facilitates their seamless integration with the concrete, ensuring a robust bond between the two materials. Moreover, steel flat bars are available in a multitude of sizes and grades, thereby allowing for customization to cater to the specific needs of the concrete structure.

- Q: Can steel flat bars be used for agricultural applications?

- Yes, steel flat bars can be used for agricultural applications. Steel is known for its strength and durability, making it suitable for various agricultural tasks. Steel flat bars can be used for constructing fences, gates, and livestock enclosures, providing a sturdy and long-lasting solution. They can also be used as support beams or braces for structures like barns or sheds. Additionally, steel flat bars can be used for creating custom implements or machinery parts, such as plow blades or cultivator tines. Overall, steel flat bars offer the necessary strength and versatility required for agricultural applications.

- Q: Do I need to make the ring galvanized flat steel ground connection between the electric well and the distribution room?

- There is also a dark, in the foundation of the house to consider the distribution of indoor total potential imbalance, in the basic reinforcement welding has been laid. Later, when installing the equipment, just connect in place

- Q: What are the common defects found in steel flat bars?

- Some common defects found in steel flat bars include surface imperfections such as scratches, pitting, and scaling. These defects can occur during the manufacturing process or during handling and transportation. Another common defect is warping, which can happen due to uneven cooling or improper storage. In addition, steel flat bars may have variations in dimensions such as width, thickness, and length, which can be considered defects if they fall outside the specified tolerances. It is important to inspect steel flat bars for these defects before using them in construction or other applications to ensure structural integrity and quality.

Send your message to us

8.79KG/M steel flat bar for construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords