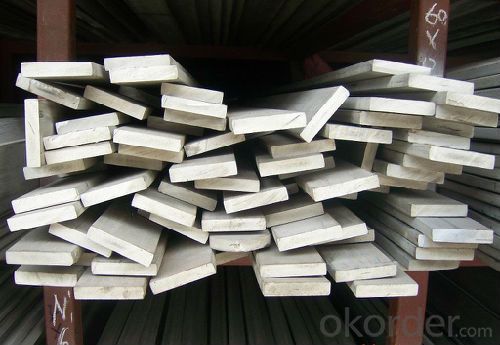

Flat Bar Hot Rolled Q235 High Quality 3MM-30MM Thickness

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering high quality Flat Bar Hot Rolled Q235 High Quality 3MM-30MM Thickness at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

According to the needs of different structures, Angle can compose to different force support component, and also can be the connections between components. It is widely used in various building structures and engineering structures such as roof beams, bridges, transmission towers, hoisting machinery and transport machinery, ships, industrial furnaces, reaction tower, container frame and warehouse etc

Product Advantages:

OKorder's Flat Bar Hot Rolled Q235 High Quality 3MM-30MM Thickness are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Manufacture: Hot rolled

Grade: Q195 – 235

Certificates: ISO, SGS, BV, CIQ

Length: 6m – 12m, as per customer request

Packaging: Export packing, nude packing, bundled

Sizes: 25mm-250mm | ||||||||||||

a*t | ||||||||||||

25*2.5-4.0 | 70*6.0-9.0 | 130*9.0-15 | ||||||||||

30*2.5-6.6 | 75*6.0-9.0 | 140*10-14 | ||||||||||

36*3.0-5.0 | 80*5.0-10 | 150*10-20 | ||||||||||

38*2.3-6.0 | 90*7.0-10 | 160*10-16 | ||||||||||

40*3.0-5.0 | 100*6.0-12 | 175*12-15 | ||||||||||

45*4.0-6.0 | 110*8.0-10 | 180*12-18 | ||||||||||

50*4.0-6.0 | 120*6.0-15 | 200*14-25 | ||||||||||

60*4.0-8.0 | 125*8.0-14 | 250*25 | ||||||||||

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

- Q: What are the different types of surface defects that can occur in steel flat bars?

- Some common surface defects that can occur in steel flat bars include scratches, pits, cracks, and rust. Scratches are shallow marks on the surface, while pits are small depressions or cavities. Cracks are more severe, as they can extend through the thickness of the bar. Rust refers to the formation of iron oxide on the surface, which can weaken the steel if not treated. These defects can affect the appearance, integrity, and performance of the steel flat bars.

- Q: How do you protect steel flat bars from UV radiation or sun damage?

- To protect steel flat bars from UV radiation or sun damage, there are several measures that can be taken. Firstly, applying a protective coating on the surface of the steel bars can help shield them from the harmful effects of UV rays. One common option for this is to use a high-quality paint that is specifically formulated for outdoor use. This paint should have UV-resistant properties to prevent fading or discoloration of the steel bars. Another effective method is to use a clear sealant or varnish that contains UV inhibitors. These products create a protective barrier on the surface of the steel, preventing the penetration of UV radiation and minimizing the risk of sun damage. It is advisable to choose a sealant that is designed for use on metal surfaces to ensure maximum effectiveness. In addition to the above measures, it is important to regularly clean and maintain the steel flat bars. This includes removing any dirt, dust, or other debris that may accumulate on the surface, as these can act as magnifiers for UV radiation, intensifying the damage. Regular inspections should also be conducted to identify any signs of corrosion or deterioration, as these can weaken the steel and make it more susceptible to UV damage. Lastly, if the steel flat bars are exposed to direct sunlight for extended periods, it is recommended to provide some form of shade or cover to reduce the intensity of UV exposure. This can be achieved by using awnings, canopies, or other types of protective structures that block or diffuse the sunlight. By implementing these protective measures, the steel flat bars can be safeguarded against UV radiation and sun damage, ensuring their longevity and maintaining their structural integrity.

- Q: How do you determine the quality of a steel flat bar?

- The quality of a steel flat bar can be determined by considering a few factors. Firstly, the material composition should be examined, including the type of steel used and any additional alloying elements. The manufacturing process and standards followed during production also play a crucial role. Inspecting the surface finish, ensuring it is smooth and free from defects or imperfections, is essential. Additionally, evaluating the dimensions, such as width, thickness, and length, to meet the required specifications is important. Finally, conducting tests for strength, hardness, and resistance to corrosion can further help in assessing the quality of a steel flat bar.

- Q: What are the different types of surface treatments available for steel flat bars?

- Steel flat bars have a variety of surface treatments available, each with its own unique benefits and characteristics. Some commonly used treatments include: 1. Hot-dip galvanizing: By immersing the steel flat bar in molten zinc, a protective layer is formed to prevent rust and corrosion. This treatment offers excellent durability and resistance to atmospheric conditions. 2. Powder coating: This method involves applying a powdered polymer coating to the surface of the steel flat bar. The powder is charged with electricity and then cured under heat, resulting in a tough and durable finish. Powder coating provides excellent resistance to impact, chemicals, and abrasion, and offers a wide range of colors and finishes. 3. Electroplating: Electroplating deposits a thin layer of metal onto the steel flat bar through an electrochemical process. The choice of metal, such as chromium, nickel, or zinc, depends on the desired properties. Electroplating enhances the appearance, corrosion resistance, and wear resistance of the steel. 4. Paint coating: Applying a paint coating to the steel flat bar is a commonly used surface treatment. This can be done through methods like spray painting or roller coating. Paint coatings not only provide a decorative finish but also protect against corrosion and environmental factors. 5. Anodizing: Although primarily used for aluminum, anodizing can also be applied to steel. This process involves creating a controlled oxidization layer on the metal's surface, enhancing corrosion resistance and providing an attractive finish. Anodizing can be done in various colors and offers excellent durability. 6. Phosphating: Phosphating treats the steel flat bar with a phosphate coating, typically by immersing it in a solution containing phosphoric acid and other chemicals. This creates a thin, crystalline layer that improves corrosion resistance and enhances the adhesion of subsequent coatings or paints. These examples represent just a few of the surface treatments available for steel flat bars. The choice of treatment depends on factors such as desired appearance, environmental conditions, and specific functional requirements.

- Q: Are steel flat bars galvanized?

- No, steel flat bars are not typically galvanized. Galvanization is a process that involves coating steel with a layer of zinc to protect it from corrosion. While galvanization is commonly used for steel products, such as pipes or sheets, steel flat bars are usually left ungalvanized as they are primarily used for structural purposes rather than for protection against rust.

- Q: Are steel flat bars suitable for electrical conductivity applications?

- No, steel flat bars are not suitable for electrical conductivity applications.

- Q: Are steel flat bars commonly used in the construction of transportation facilities?

- Steel flat bars are widely utilized in the construction of transportation facilities due to their versatility and strength. They are well-suited for numerous applications in transportation infrastructure, such as framing structures, reinforcing concrete, and serving as support beams in bridges and highways. The exceptional load-bearing capacity and resistance to bending that steel flat bars offer make them an excellent choice for constructing transportation facilities capable of withstanding heavy loads and adverse weather conditions. Moreover, steel flat bars are readily accessible in various sizes and can be conveniently fabricated to meet specific design requirements, which makes them a favored material in the construction industry.

- Q: What are the common methods of surface finishing for steel flat bars?

- There are several common methods of surface finishing for steel flat bars. These methods are used to enhance the appearance, improve corrosion resistance, and increase the durability of the steel flat bars. One of the most common methods is hot-dip galvanizing. In this process, the steel flat bars are immersed in a molten zinc bath, which forms a protective zinc coating on the surface. This coating provides excellent corrosion resistance and protects the steel from rust and oxidation. Another method is electroplating, which involves the deposition of a thin layer of metal onto the surface of the steel flat bars. This can be done using various metals such as chromium, nickel, or zinc. Electroplating not only enhances the appearance of the steel flat bars but also provides protection against corrosion. Powder coating is another popular method of surface finishing for steel flat bars. In this process, a dry powder is electrostatically applied to the surface of the steel, and then cured under heat to form a durable and aesthetically pleasing coating. Powder coating provides excellent corrosion resistance, abrasion resistance, and chemical resistance. Shot blasting is a mechanical method used to clean and prepare the surface of steel flat bars. In this process, small steel shots are blasted at high velocity onto the surface of the flat bars, removing any rust, scale, or contaminants. Shot blasting leaves the surface clean, smooth, and ready for further finishing processes such as painting or coating. Lastly, painting is a commonly used method of surface finishing for steel flat bars. Different types of paints, such as epoxy, polyurethane, or enamel, can be applied to the surface to provide protection against corrosion and improve the appearance of the steel. Overall, these methods of surface finishing for steel flat bars offer various benefits such as corrosion resistance, enhanced appearance, and improved durability, making them suitable for a wide range of applications. The choice of the method depends on the specific requirements and conditions in which the steel flat bars will be used.

- Q: Are steel flat bars commonly used in the mining industry?

- Yes, steel flat bars are commonly used in the mining industry. They are utilized for various applications such as structural support, fabrication of machinery and equipment, as well as reinforcement in underground tunnels and shafts. The high strength and durability of steel make it a preferred material in this industry where heavy loads, extreme conditions, and safety are paramount.

- Q: Are steel flat bars used in the manufacturing of appliances?

- Yes, steel flat bars are commonly used in the manufacturing of appliances. Steel is a durable and strong material that offers excellent structural integrity, making it ideal for appliances that require stability and support. Steel flat bars are often used in the construction of appliance frames, brackets, and structural components. They provide a solid foundation for various appliance parts and help ensure the longevity and reliability of the finished product. Additionally, steel flat bars can be easily shaped and welded, allowing manufacturers to create customized designs and configurations to suit specific appliance requirements.

Send your message to us

Flat Bar Hot Rolled Q235 High Quality 3MM-30MM Thickness

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords