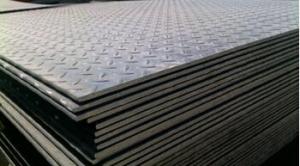

First Class Hot Rolled Steel Coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product: | Hot Rolled Steel Coils/Sheets |

Material: | Q195,Q235,A36,SS400,S235JR,Q345,ST37-2, CCSB etc |

Standard : | JIS G3002 GB/T251B |

Technique: | hot rolled |

Thickness | 1.2mm to 200mm |

Tolerance of thickness: | :+/-0.03mm |

Width: | 750mm-2000mm |

Tolerance of width: | :+/-5.00mm (aiming to +/-2.00mm) |

Normal width: | 914mm, 1000mm, 1200mm, 1219mm, 1250mm,1500mm |

Length: | According to requirement |

Coil ID: | 508mm-610mm |

Coil Weight: | 10-25 Metric Tons |

Surface: | Black, Chromate, fingerprint resistant treatment, slight oiled or non-oiled, dry |

Port of Loading: | Tianjin/Shanghai port |

Packaging Details: | Standard export packing or according to the clients required |

Delivery Time | Within 30 days after received 30% deposit or workable L/C |

Payment Terms: | L/C,T/T |

|

|

- Q: How do steel coils contribute to sustainable construction?

- Steel coils contribute to sustainable construction in several ways. Firstly, steel is a highly durable material that can withstand extreme weather conditions and resist corrosion, leading to longer-lasting structures. This durability reduces the need for frequent repairs and replacements, thereby reducing waste and conserving resources. Secondly, steel is a recyclable material, meaning that at the end of a building's life cycle, the steel used in its construction can be easily and efficiently recycled. This reduces the demand for new steel production, which is energy-intensive and releases greenhouse gases. By using steel coils made from recycled steel, the construction industry can significantly reduce its environmental impact. Additionally, steel coils are versatile and can be shaped and formed into various structural components, allowing for efficient use of materials and minimizing waste. The lightweight nature of steel coils also makes transportation and handling more cost-effective and environmentally friendly. Furthermore, using steel coils in construction can contribute to energy efficiency. Steel has excellent thermal conductivity, which means it can effectively transfer and distribute heat, enabling better insulation and reducing energy consumption for heating and cooling. Overall, steel coils play a vital role in sustainable construction by promoting durability, recyclability, efficient material usage, and energy efficiency.

- Q: Nickel is ferro magnetic in nature. But when it is added with stainless steel, it makes stainless steel non-magnetic. What is the structural changes happened with the presence of nickel?

- All stainless steel is non magnetic.

- Q: - I'm considering doing my physics coursework on the uses of Mild Steel in skyscrapers and construction, would this be right? Some sources tell me mild steel is too weak, others say it is fine

- Mild steel doesn't really mean anything, technically. In today's world all steel is mild steel unless it's high carbon or alloy, which are mostly tool steels. You'll need to study steel much deeper than that to accomplish any real physics work relating to steel.

- Q: What are the different types of steel coil surface defects?

- There are several different types of steel coil surface defects that can occur during the manufacturing or handling process. Some of the common types include: 1. Rust: Rust is a common surface defect that occurs when the steel coil is exposed to moisture or oxygen. It appears as a reddish-brown discoloration on the surface of the coil. 2. Scratches: Scratches are superficial marks that can occur during handling or transportation of the steel coil. They can vary in depth and severity, ranging from light surface scratches to deep gouges. 3. Stains: Stains are another type of surface defect that can occur due to exposure to chemicals or other substances. They can appear as discolored patches on the surface of the coil, and may be difficult to remove. 4. Roll marks: Roll marks are impressions or indentations that can occur during the rolling process. They are caused by uneven pressure or misalignment of the rolls, and can appear as lines or patterns on the surface of the coil. 5. Edge wave: Edge wave is a defect that occurs when the edges of the coil are not perfectly flat. It can cause the edges to appear wavy or uneven, and may affect the overall appearance and performance of the coil. 6. Oil spots: Oil spots are surface defects that occur when oil or lubricants used in the manufacturing process are not properly removed. They can appear as dark spots or patches on the surface of the coil, and may affect the adhesion of coatings or paints. 7. Pitting: Pitting is a defect that appears as small, shallow depressions or pits on the surface of the coil. It can be caused by factors such as corrosion, uneven cooling, or impurities in the steel. 8. Holes: Holes are more severe surface defects that can occur due to a variety of reasons, such as corrosion, mechanical damage, or manufacturing errors. They can range in size and can significantly affect the structural integrity of the coil. It is important to address these surface defects promptly to ensure the quality and performance of the steel coil. Regular inspections, proper handling, and appropriate surface treatments can help minimize the occurrence of these defects.

- Q: How are steel coils welded together?

- Different methods can be employed to weld steel coils together, depending on the specific requirements and the type of steel being used. Electric resistance welding (ERW) is a common method where an electric current is utilized to generate heat in the coils, melting their edges. Pressure is then applied to join them together. ERW is a cost-effective and speedy technique for welding steel coils. Thinner steel coils are often welded using high-frequency induction welding (HFIW). This involves the use of an induction coil to produce an alternating magnetic field, inducing an electric current in the coils. The resistance of the coils to this current generates heat, causing the edges to melt and form a weld. For thicker and heavier steel coils, submerged arc welding (SAW) is commonly employed. This technique utilizes a granular flux and a continuous electrode that is fed into the weld area. The flux melts, creating a protective shield for the weld pool, while the electrode melts to form the weld. SAW is a robust and efficient method for welding steel coils. In addition to these methods, laser welding and gas metal arc welding (GMAW) can also be utilized for welding steel coils. Laser welding offers high precision and speed, while GMAW, also known as MIG welding, utilizes an electric arc between a consumable wire electrode and the steel coils to create a weld. Irrespective of the welding method employed, successful welding of steel coils hinges on proper edge preparation, maintenance of appropriate heat and pressure levels, and the use of correct welding techniques.

- Q: i wanna know all the similarities between iron and steel

- 1. Both victim of corrosion

- Q: Which one has more electrical resistivity? Wood or steel? And why?I know that the resistivity depends on the material of the conductor, but i want a perfect explaination please.Thnx in advance :)

- Wood, and it depends on the elements making up the 'conductor' .. and how 'mobile' electrons are in the material .. To a first approximation (non-exotic materials), if the elements form molecules where electrons are 'weakly bound', then that material will conduct electricity. The 'weaker' the binding (and the more electrons), the better the conductor .. (it is, of course, much more complicated than that .. see link)

- Q: Hi All,I was wanting to know,on the quality bikes such as Trek,Giant etc is the aluminum frames as strong as the steel frame bikes? I have heard conflicting reports on this,so thought I would ask here for more input.Thanks!

- Steel is stronger than aluminum. But, you have to consider the strength to weight ratio and stiffness. Modern aluminum frames use hydro-forming to optimize the tube shapes. They also use modern welding and bonding techniques. In short, a good aluminum frame can be better than a steel frame and have less weight. Consider a Cannondale CAAD alloy frame or a hybrid composite/alloy frame such as a Cannondale Six. Cannondale is know for pioneering alloy frames.

- Q: What are the different types of coil recoiling machines?

- The different types of coil recoiling machines include manual coil recoilers, semi-automatic coil recoilers, and fully automatic coil recoilers.

- Q: Is there any other way of testing whether or not you have a 1944 Steel penny that won't damage the penny. The magnet test doesn't seem to work cause even when I try to get a 2007 penny to stick to the magnet...it won't. So is there some kind of magnet needed? Like power wise or anything like that, if not then I need to know what are other ways of testing the 1944 penny.

- 1944 Penny Steel

Send your message to us

First Class Hot Rolled Steel Coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords