Fireclay Brick - Superior Thermal Insulation

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t

- Supply Capability:

- 10000000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

What is the feature of Fireclay Brick?

l Fireclay Bricks or fire bricks are the most widely used refractory bricks because of its great features: low thermal conductivity, good thermal insulation performance; High resistance to Thermal shock, abrasion, chemical attack to provide long service life; easy operation and installation; broad usage or applications and low price etc.

Feature of Fireclay Bricks

Low thermal conductivity

High refractoriness

High mechanical strength

Excellent thermal shock resistance

Application of Fireclay Bricks

CMAX fireclay bricks are commonly applied in blast furnace, hot blast furnace, teeming ladle, glass furnace, etc.

Image of Fireclay Brick

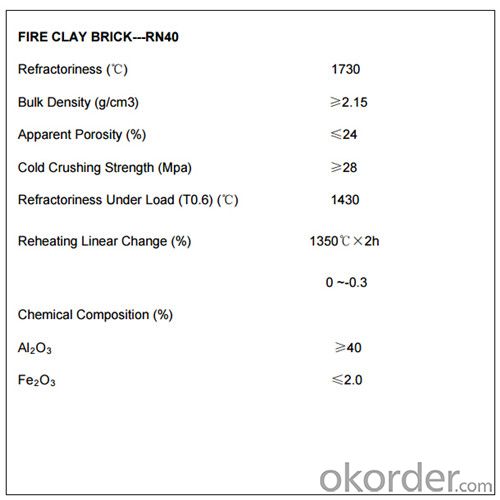

Technical Data of Fireclay Brick

FAQ

Q1: How do you control the products quality?

A1: With strict quality control system throughout the materials selection and production process, our refractory and ceramic fiber products quality is effectively controlled to meet customer requirements.

From the raw materials selecting, our quality control begin. The quality certificates of raw materials are required and each batch will be tested before using. During production, the quality control is conducted by workers and then each piece will be sorted and examined by quality supervisor.

Q2: What`s the lead time for my order?

A2: It depends on customers’ requirements and our production schedule. And usually we need 30-60 days

for refractory bricks, 10-25 days for unshaped refractory materials and 10-20 days for ceramic fiber blankets.

Q3: Can you offer Door-to-Door delivery?

A3: Yes, but only for some countries such as U.S., UAE, Saudi Arabia, Iran, and Russia, etc.

Q4: What is the minimum quantity?

A4: There is no minimum order quantity. Depending on the item and processing, there may be a minimum production required, however we can offer a quotation based only on the quantity you need.

Q5: Can you give me a brief introduction of the application of your products?

A5: CNBM (China National Building Material) core refractory business comprises the production, sale and installation of high-grade refractory products, the development and implementation of customized system solutions as well as rendering outstanding services for the key industries in Glass, Iron& Steel, Petrochemical, Cement, Ceramic and Nonferrous Metals.

- Q: What kind of coal should be used to burn refractory brick? and how many calories smoke is suitable?

- It can't be the surface of coal, at least it is coal seed.

- Q: Why is the house made of refractory bricks not warm in winter

- Heating equipment can be used

- Q: What materials make of clay insulating fireclay brick?

- Clay insulation bricks are general according to the different origins of raw materials, not the same

- Q: What are the release agents of refractory bricks?

- Alkalinity, the production process of alkaline, acid and alkali resistant transparent instant thickening powder, you can adjust the proportion according to the cost and needs of quality, environmental protection: One: Add the preservative into water to mix, after soaking one hour, then mixing evenly the production ratio, and then add the super core release agent into water to mix, add flavor pigment masterbatch into water to mix with water mixing, ensure completely dissolved, then add the waste oil, falvor is appropriate amount= release agent. Two, the newest recipe of release agent super core release agent masterbatch, waste engine oil, water, instant acidproof and alkaliproof transparent thickening powder, wire drawing powder, preservative, flavor and pigment= release agent super core wire drawing powder with water mixing, it is the most newly developed special core masterbatch and engine oil of Chengdu Hengfeng Hongye detergent factory, and it doesn't contain toxic solvents, especially 1, it has the following features, after thickening more than half an hour or so, mix evenly is ok, in a few seconds will waste oil and alkali: 10% of waste engine oil, 20% of release agent core masterbatch, 88% of water, 500g instant acidproof alkaliproof transparent thickening powder, 80g wire drawing powder, 1g pigment and preservative and lubricating oil and industrial grease, these integrate with water.

- Q: What is the material of refractory brick used in the high temperature zone of the kiln?

- The ordinary generally use clay high alumious fireclay brick. GB/T 3994-2005 insulating refractory brick. What with good material is high-grade thermal insulation refractory brick. GB/T 3995-2006, high alumina thermal insulation refractory brick , model A13, is made of aluminium oxide, A13 50U, senior heat insulatio brick B5

- Q: Why should the clay bricks be watered first when they are building masonry walls?

- Therefore, in order to facilitate the operation, so that the mortar has a suitable hardening and strength growth environment, to ensure the quality of masonry, bricks must be watered before use wet.

- Q: What matters should be noticed when using clay refractory bricks in a glass kiln?

- There are a variety of products for the production of shaped and unshaped refractory clay, such as blast furnace insulation and high alumina bricks. Brick products include refractory clay bricks, plastic materials for overload, refractory clay and high alumina casting materials, etc.. In the amorphous part, if to support the horizontal induction furnace and the straight induction furnace lining, such as refractory clay and high alumina plastic

- Q: does 90m high reinforced concrete chimney need firebrick?

- The chimney need firebricks or casting fire or acid resisitant concrete after casting, one aim is to resist high temperature, then is to resist acid corrosion. there is a variety of models of the refractory brick , you can refer to the installation quota.

- Q: Where are clay bricks or cement bricks?

- Are clay bricks made of ordinary buildings or clay bricks on refractory materials?. Ordinary clay brick building is a burning clay made of red brick, (that is, the original old house with a little red brick) due to its extensive use of native resources and have great pollution in firing, now in some city has banned the use of the.

- Q: MU10 what are the non clay solid bricks?

- Clay solid brick with clay and is needed by adding admixture as raw materials, solid bricks by water mixing, molding, high temperature calcination made, mainly used for masonry bearing and non bearing wall, wall materials is a kind of widely used.

Send your message to us

Fireclay Brick - Superior Thermal Insulation

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t

- Supply Capability:

- 10000000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords