Fireclay Brick for Refractory Heat Insulation

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

High alumina fireclay Brick for Heating Furnace is a kind of insulation material adopting organic matter as ignition loss substance in order to increase the porosity of refractory, which has such advantages as high porosity, small volume density, good insulation effect, high mechanical intensity, small thermal conductivity and long service life. For various industrial kilns & furnaces, it is a kind of essential refractory for energy saving and temperature preservation.

This series of High Alumina fireclay Brick for Heating Furnace are made of selected high alumina bauxite, kaolin clay, hollow microsphere as the mian material.By shaping at high pressure and sintering at high temperature

Product Applications:

1. Furances of glass,coke oven,electric and so on

2.Furnaces of metallurgy industry, heat treatment furnace

3. Furnaces of chemical industry and construction industry.

4. Furnace of incineration of garbage, recirculating fluidized bed furnace

Main Product Features:

1. Low porosity,High bulk density.

2. High Cold Crushing strength.

3. High refractoriness under load.

4. High mechanical strength.

5. Good resistance to erosion.

Product Specifications:

1.With 55% Al2O3 min;

2. Refractoriness: 1750C min;

3.For steelmaking furnaces;

4.ISO 9001 Certificate;

5.Custom shape;

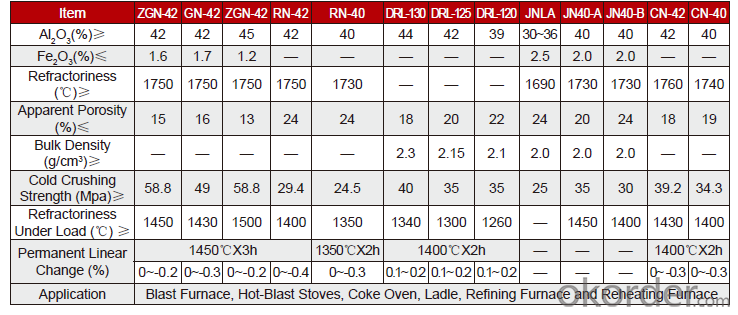

Technical data:

FAQs:

Q1 What’s the transport method?

A1 FCL delivery goods with wooden pallet or wooden case by sea; If LCL delivery, must with wooden case; Sometimes need open top, flat rack or bulk cargo.

Q2 What’s the required payment term?

A2 Generally 30% TT as the prepayment, 70% TT before delivery. If need, 100% Irrevocable Letter of Credit or negotiation.

Q3 Which country are our products exported to?

A3 Apart from entire Chinese market, the US, Russia, Japan, Korea, Australia and some Southeast Asian Nations.

- Q: can the red brick be used as refractory brick?

- 1200---1750 of the refractory bricks, below 1000 degrees of red brick brick is ok.

- Q: What are required for high temperature refractory bricks?

- High temperature resistance, high pressure resistance

- Q: What are the ingredients of brick?

- Is the most traditional brick masonry material, its composition is clay as the main raw material gradually to the development of industrial waste utilization of coal gangue and fly ash, and by solid and hollow porous to development, development by sintering to non sintering.

- Q: What is the refractory brick in silicious model?

- Adding appropriate amount of mineralized agent to promote the transformation of quartz in the body into phosphorus quartz. Smaller coefficient of thermal expansion. Also used in high temperature bearing part of hot blast stove and acid open hearth furnace, refractory materials and ceramic kiln, kiln vault and other load-bearing parts, thermal shock resistance variation. High temperature strength. the glass furnace is burnt in 1430 to 1350 degrees Celsius in the reducing atmosphere. use natural silica as raw materials. True density 2. more than 93% of silica content. generally there is no crystal type transformation above 600 degrees celsius. With acid slag erosion and sediment chamber regenerator performance, soaking furnace, open hearth furnace. there is more crystal type transformation below 600 degrees celsius. mainly used in coking chamer of coke oven and partition of firebox. acid refractory material made of high thermal shock resistance, large volume change, square quartz and a small amount of residual quartz and glass box . Long term use at high temperature without deformation

- Q: What is the difference between a clay brick and a red brick?

- Clay bricks burn red and red brick. Burnt blue. Green brick.Clay bricks are called sintered clay bricks.The construction methods are the same as those of the two. No difference.

- Q: What are the sizes and sizes of clay bricks?

- According to the compressive strength (Newton / square millimeter, N/mm2) the size is divided into MU30, MU25, MU20, MU15, MU10, MU7.5, these 6 intensity levels.The bigger the size, the stronger the compressive strength.

- Q: is there any requirement for radioactive materials in refractory materials.

- they all do not cause radiological hazards to the environment, so no requirements! analyze rom the element , magnesia. Do not know if it is useful, but material used by refractory materials, firstly any chemical elements are radioactive, human beings can not close, then, such as silicon dioxide: If it is radioactive. analyze from use, such as bauxite, does not have the use value

- Q: What are the properties of clay bricks?

- The clay brick belongs to weak acid refractory. Because of the fluctuation of chemical composition, the production method is different, and the difference of sintering temperature makes the properties of clay brick change greatly. Ordinary clay bricks are divided into (NZ) 1, 40, (NZ) 1, 35, (NZ) 1, 30, three trademarks on the basis of the amount of Al2O3 content in the components.

- Q: Can porous clay bricks be made of 12 walls to bear weight?

- With the production of low energy consumption, convenient construction and waste utilizing, light weight, high strength, good insulation effect, durability, low shrinkage, regular appearance and other characteristics, is an ideal material to replace sintered clay brick.

- Q: Why do some people say that clay brick insulation effect is good, and some people say that bad, in the end what is right?

- Now is the best thermal insulation hollow powder briquette, because it is hollow, blocking the heat transfer, plus foam insulation on the outside, good insulation effect,

Send your message to us

Fireclay Brick for Refractory Heat Insulation

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords