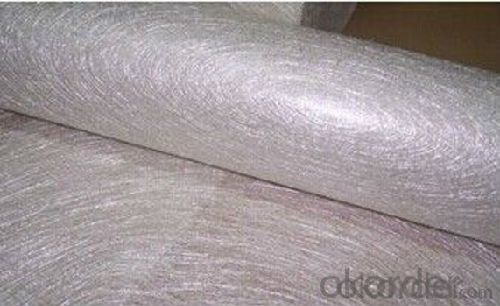

Fiberglass Mat Tissue - Fiberglass Stitched Mat 300g 150~2600mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description & application | ||||||||||||||||||||||||

◎ The stitched mat is made of chopped strand which randomly dispersed and be stitched together by polyester thread. The width is available from 150-2400mm.Density of mat generally is 300-600g/m2.

| ||||||||||||||||||||||||

| ||||||||||||||||||||||||

◎ Uniform thickness, good wet tensile strength retention. ◎ Excellent mechanical properties. | ||||||||||||||||||||||||

| ||||||||||||||||||||||||

| ||||||||||||||||||||||||

| ||||||||||||||||||||||||

Each roll is wrapped by PE film and then packed into carton. Stacking in bulk or palletized is available, the pallet shall be no higher than 2 layers.

|

FAQ

1) Which delivery term will you usually offer?

We usually offer FOB Chongqing, FOB Shenzhen, FOB Shanghai or CIF port (defined by the customer).

2) What are the specialties on your company?

We specialized in Reliable quality material, good technical guidance, and full range of products (from High end to off – grade quality materials and cover most of glass fiber products) in order to meet different customer’s requirements. We have close contact with major glass fiber manufacturers in China that can save you too much time.

- Q: How is fiberglass mat tissue used in the production of windshields?

- Fiberglass mat tissue is a crucial component in the production of windshields due to its unique properties and functions. When manufacturing windshields, the fiberglass mat tissue is used as a reinforcement material to enhance the strength and durability of the glass. During the production process, a layer of fiberglass mat tissue is inserted between two layers of glass to create a laminated structure. This layer acts as a barrier, preventing the glass from shattering into small dangerous pieces upon impact. It helps to hold the glass together, providing safety to the vehicle occupants. The fiberglass mat tissue serves as a reinforcing material, improving the mechanical properties of the windshield. It enhances the impact resistance, making the windshield less prone to cracks or chips from stones, debris, or other objects that may hit it while driving. This reinforcement also adds structural integrity to the windshield, allowing it to withstand extreme weather conditions and vibrations without compromising its functionality. Furthermore, the fiberglass mat tissue helps to reduce noise transmission and vibrations. It has sound-damping properties, which contribute to a quieter and more comfortable driving experience by reducing external noise from entering the vehicle cabin. Additionally, the use of fiberglass mat tissue allows for the production of curved windshields. The flexibility of the material enables it to conform to different shapes and contours, allowing manufacturers to create windshields with customized designs and improved aerodynamics. In summary, fiberglass mat tissue plays a vital role in the production of windshields. Its reinforcement properties enhance the strength and impact resistance of the glass, providing safety to the vehicle occupants. It also contributes to a quieter driving experience and enables the production of curved windshields with improved aerodynamics.

- Q: Can fiberglass mat tissue be used for flooring insulation?

- No, fiberglass mat tissue is typically not used for flooring insulation. It is more commonly used in applications such as roofing, wall insulation, and soundproofing. For flooring insulation, materials like foam, cellulose, or mineral wool are typically preferred.

- Q: What are the different reinforcement orientations available for fiberglass mat tissue?

- Fiberglass mat tissue offers several reinforcement orientations, each intended for specific purposes in different applications. One common orientation is unidirectional reinforcement, where fibers align in one direction. This orientation provides great strength and stiffness in that alignment, making it suitable for applications requiring resistance to tension or bending forces in a single direction. Another orientation is bidirectional reinforcement, where fibers align in two perpendicular directions. This orientation provides equal strength and stiffness in both directions, making it ideal for applications needing resistance to tension and compression forces. Structural components like panels, pipes, and tanks commonly employ bidirectional reinforcement. A third orientation is randomly oriented reinforcement, where fibers distribute randomly. This orientation offers isotropic properties, meaning it provides similar strength and stiffness in all directions. Random reinforcement is often used in applications requiring uniform strength and flexibility, like automotive parts, boat hulls, and sporting goods. Furthermore, hybrid reinforcement orientations are available, combining different fibers or orientations to meet specific performance requirements. These hybrids offer a combination of strength, stiffness, flexibility, and other desired properties, making them suitable for a wide range of applications. Overall, the choice of reinforcement orientation for fiberglass mat tissue depends on the application's specific requirements, including desired mechanical properties, forces to be resisted, and other performance considerations.

- Q: How is fiberglass mat tissue used in the construction industry?

- Fiberglass mat tissue is widely used in the construction industry for various applications. This material is made up of thin strands of glass fibers that are bonded together with a resin. It offers several properties that make it suitable for construction purposes. One common use of fiberglass mat tissue is in the production of roofing materials. It is often used as a reinforcement layer in roofing shingles or sheets. The fiberglass mat tissue adds strength and durability to the roof, making it more resistant to weather elements such as wind, rain, and hail. Additionally, it helps to prevent cracking and splitting, prolonging the lifespan of the roofing material. Another application of fiberglass mat tissue in the construction industry is in the production of composite materials. It is commonly used as a reinforcement layer in composite panels and boards. The fiberglass mat tissue enhances the strength and stiffness of the composite material, making it suitable for various structural applications. It is also lightweight, which makes it an ideal choice for building materials that require both strength and reduced weight. Fiberglass mat tissue is also used in the construction of walls and ceilings. It can be applied as a layer between the gypsum board and the insulation material to provide additional strength and resistance to impacts. This helps to prevent cracks and damage to the walls or ceilings, enhancing the overall structural integrity of the building. Furthermore, fiberglass mat tissue finds application in the construction of pipes and tanks. It is used as a reinforcement layer in the manufacturing of fiberglass-reinforced plastic (FRP) pipes and tanks. The fiberglass mat tissue adds strength and rigidity to the FRP structure, making it suitable for various industrial applications, including chemical processing, wastewater treatment, and oil and gas industries. In conclusion, fiberglass mat tissue is widely used in the construction industry for its strength, durability, and lightweight properties. It is utilized in roofing materials, composite panels, walls, ceilings, pipes, and tanks, among other applications. Its versatility and performance make it a preferred choice among construction professionals for enhancing the structural integrity of various building components.

- Q: Is fiberglass mat tissue biodegradable?

- No, fiberglass mat tissue is not biodegradable. Fiberglass is a synthetic material made from fine fibers of glass, which are woven together to create a strong and durable material. These fibers do not break down naturally over time, making fiberglass mat tissue non-biodegradable.

- Q: Is fiberglass mat tissue resistant to moisture vapor transmission?

- Yes, fiberglass mat tissue is resistant to moisture vapor transmission. It is a highly durable and moisture-resistant material that is commonly used in various applications where moisture control is important, such as in roofing, insulation, and flooring. The fiberglass mat tissue is specifically designed to prevent the transmission of moisture vapor, helping to maintain the integrity and performance of the materials it is used with. Its resistance to moisture vapor transmission makes it an ideal choice for environments where moisture control is critical.

- Q: Does fiberglass mat tissue require any special precautions during disposal?

- Yes, fiberglass mat tissue does require special precautions during disposal. Due to its composition, fiberglass mat tissue can release fine particles and fibers into the air when handled or broken. These particles and fibers can be harmful if inhaled or come into contact with skin and eyes. Therefore, it is important to take certain precautions when disposing of fiberglass mat tissue. Firstly, it is recommended to wear appropriate personal protective equipment (PPE) such as gloves, goggles, and a respirator mask to minimize the risk of exposure. This will help prevent the inhalation of airborne particles and fibers and protect the skin and eyes from any potential irritation. Secondly, fiberglass mat tissue should be disposed of in sealed bags or containers to prevent any loose fibers from becoming airborne during transportation. It is also advisable to label the bags or containers as "hazardous" or "fiberglass waste" to alert others of the potential risks. Furthermore, it is important to follow local regulations and guidelines for the disposal of fiberglass mat tissue. Depending on the location, there may be specific requirements for handling and disposing of hazardous waste materials, including fiberglass. These regulations are in place to protect public health and the environment. In summary, fiberglass mat tissue does require special precautions during disposal to minimize the risk of exposure to harmful particles and fibers. Wearing appropriate protective equipment, using sealed containers, and following local regulations are essential steps to ensure safe disposal practices.

- Q: Can fiberglass mat tissue be used for automotive parts?

- Yes, fiberglass mat tissue can be used for automotive parts. Fiberglass mat tissue is a versatile material that provides strength, rigidity, and durability. It is commonly used in the automotive industry for various applications such as reinforcing panels, bumpers, hoods, and body parts. The fiberglass mat tissue is lightweight, making it suitable for reducing the overall weight of the vehicle and improving fuel efficiency. Additionally, it is resistant to corrosion, chemicals, and extreme temperature conditions, making it a reliable choice for automotive parts. The material's flexibility also allows for easy molding and shaping, enabling manufacturers to create complex designs and achieve desired aesthetics. Overall, fiberglass mat tissue is an excellent option for automotive parts due to its strength, durability, lightweight nature, and versatility.

- Q: How does fiberglass mat tissue compare to mineral wool insulation?

- Fiberglass mat tissue and mineral wool insulation are two common types of insulation materials used in construction and other industries. While both materials serve the purpose of providing thermal insulation, there are some differences between the two. Fiberglass mat tissue is made from fine glass fibers that are bonded together to form a mat. It is lightweight and flexible, making it easy to handle and install. Fiberglass mat tissue is also resistant to moisture, mold, and pests, making it a durable option for insulation. It has a high R-value, which measures the material's ability to resist heat flow, making it an effective insulator. On the other hand, mineral wool insulation is made from natural minerals such as basalt, diabase, or slag. It is typically denser and heavier than fiberglass mat tissue. Mineral wool insulation is known for its excellent fire resistance properties, as it is non-combustible and can withstand high temperatures. It also provides sound insulation, reducing noise transmission. However, mineral wool insulation can absorb moisture, which can reduce its effectiveness over time. In terms of thermal performance, both materials offer similar levels of insulation. However, fiberglass mat tissue tends to be slightly more efficient due to its higher R-value. Additionally, fiberglass mat tissue is generally more affordable compared to mineral wool insulation. In conclusion, fiberglass mat tissue and mineral wool insulation are both effective insulation materials. The choice between the two will depend on specific project requirements, such as fire resistance, sound insulation, cost, and moisture resistance. It is important to consider these factors and consult with professionals to determine the most suitable insulation material for a particular application.

- Q: Can fiberglass mat tissue be used for electrical enclosures?

- No, fiberglass mat tissue is not typically used for electrical enclosures. Electrical enclosures are designed to protect electrical equipment from outside elements like dust, moisture, and physical damage. They are usually made from materials that provide insulation and have high mechanical strength, such as sheet metal, plastic, or fiberglass reinforced plastic (FRP). While fiberglass mat tissue can provide some level of mechanical strength and insulation, it is not commonly used as the primary material for electrical enclosures due to its limited durability and lower resistance to moisture and impact.

Send your message to us

Fiberglass Mat Tissue - Fiberglass Stitched Mat 300g 150~2600mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords