Fiberglass Mat Tissue Glasswool Blanket Fire Protection Glass Wool Insulation

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of Glass Wool Blanket:

Glass wool, which belongs to glass fiber , is a kind of man-made inorganic fiber. It is made from fibrosis glass melt in wool shape, which belongs to inorganic fiber and fiber in its chemical ingredient. Its merit is better in shape, low density and volume, low in thermal conduction, better heat preservation and thermal insulation, fine sound absorption, corrosion-resistant and stable chemical property.

It is widely used for heat insulation and sound absorption in industrial workshops, warehouses, public facilities, exhibition centers, shopping malls, and a variety of indoor playgrounds, sports stadiums and etc.

2.Main features of Glass Wool Blanket:

• Sound absorption and noise reduction; it can effectively prevent sound from spreading.

• Grade A1 incombustible materials.

• Easy for construction; cutting at will.

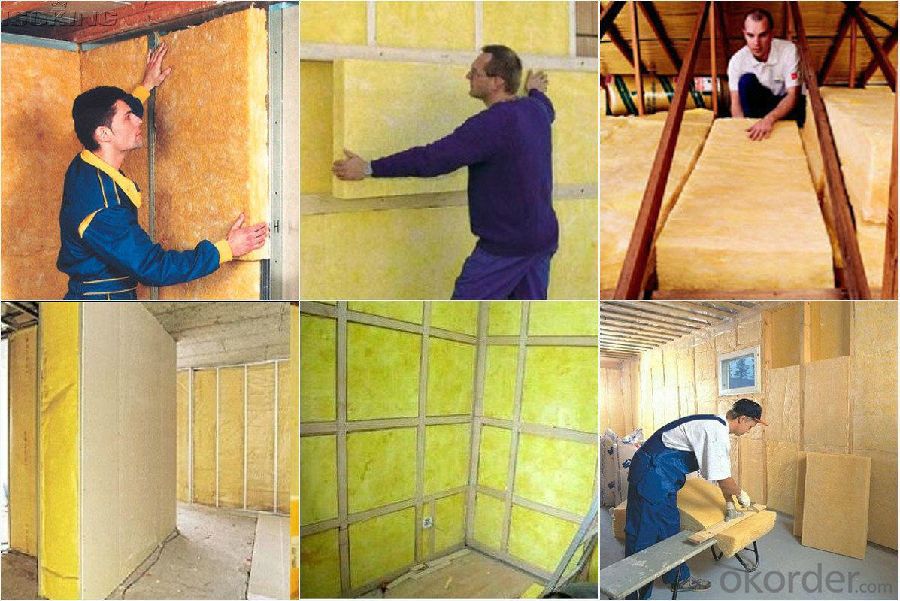

3.Glass Wool Blanket Images:

4. Glass Wool Insulation Blanket Technical Parameters:

Property | High/low temperature resistance, oil and fuel resistance, weathering resistance, O zone resistance etc. |

Shape | According to your requirement. |

Color | Any color is available ,according to your requirements. |

Material | NBR, CR, SBR, EPDM, IIR, NR, EP, Silicone, VITON etc. |

Hardness | 30-90ShoreA |

Delivery | In 10 days |

Packing | Plastic bag & carton box or according to your requirements. |

Application | Electronic field, industrial machine & equipment, house-hold appliance, telecommunication, automobile, medical equipment industry etc. |

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of Glass Wool Blanket is one of the large scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system every link from raw material to final product we have strict quality test; We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: Is fiberglass mat tissue safe to handle?

- Yes, fiberglass mat tissue is generally safe to handle. However, it is important to take certain precautions such as wearing protective gloves and a mask to avoid skin irritation or inhalation of fibers.

- Q: Is fiberglass mat tissue resistant to alkalis?

- Yes, fiberglass mat tissue is resistant to alkalis. It is commonly used in construction and industrial applications where it may come into contact with alkaline substances such as cement or concrete. The fiberglass mat tissue is designed to have a high resistance to alkalis, ensuring its durability and longevity in these environments. This resistance is due to the chemical composition and structure of the fiberglass, which allows it to withstand the corrosive effects of alkalis without degradation. Therefore, fiberglass mat tissue is a reliable choice for projects that involve exposure to alkalis.

- Q: Can fiberglass mat tissue be used for composite pipe manufacturing?

- Yes, fiberglass mat tissue can be used for composite pipe manufacturing. Fiberglass mat tissue provides reinforcement to the composite pipe, enhancing its strength, durability, and resistance to corrosion.

- Q: How is fiberglass mat tissue used in the production of chemical reactors?

- Due to its exceptional properties, fiberglass mat tissue is commonly utilized in the production of chemical reactors. Composed of randomly oriented glass fibers bonded together with a binder material, this tissue is ideal for constructing these reactors. A primary application of fiberglass mat tissue in chemical reactors is as a reinforcement material. It is typically applied to the inner surfaces of the reactor to enhance its structural integrity. The combination of glass fibers and binder creates a durable and strong layer capable of withstanding harsh conditions within the reactor, such as high temperatures and corrosive chemicals. Moreover, fiberglass mat tissue acts as a protective barrier against chemical attack. Traditional materials often degrade when exposed to aggressive substances found in chemical reactors. However, the chemical resistance of fiberglass mat tissue makes it highly suitable for such environments. It effectively prevents corrosive chemicals from penetrating the reactor walls, ensuring the long-lasting reliability of the equipment. Additionally, fiberglass mat tissue offers thermal insulation properties to chemical reactors. This is particularly crucial in processes where temperature control is vital. The insulation capabilities of the tissue help maintain the desired temperature within the reactor, preventing heat loss or gain that could negatively impact the efficiency and consistency of chemical reactions. In conclusion, fiberglass mat tissue plays a vital role in the production of chemical reactors by reinforcing the structure, providing chemical resistance, and offering thermal insulation. Its unique properties make it an excellent choice for ensuring the durability, safety, and optimal performance of chemical reactors in various industrial applications.

- Q: Is fiberglass mat tissue suitable for automotive panel repairs?

- Yes, fiberglass mat tissue is suitable for automotive panel repairs. Fiberglass mat tissue is a versatile and durable material that is commonly used in automotive repairs. It is particularly effective for repairing and reinforcing damaged or weakened areas on automotive panels. Fiberglass mat tissue provides a strong and stable foundation for repairing dents, cracks, or holes in panels, and it can be easily shaped and molded to fit the contours of the panel. Additionally, fiberglass mat tissue is resistant to rust and corrosion, making it a reliable choice for automotive repairs that need to withstand harsh weather conditions and road debris. Overall, fiberglass mat tissue is a suitable and widely-used material for automotive panel repairs due to its strength, durability, and versatility.

- Q: Can fiberglass mat tissue be used for insulation in pharmaceutical storage areas?

- Yes, fiberglass mat tissue can be used for insulation in pharmaceutical storage areas. Fiberglass mat tissue is a versatile material that offers excellent thermal insulation properties. It is often used in various industries, including pharmaceuticals, due to its ability to regulate temperature and provide insulation against heat transfer. In pharmaceutical storage areas, maintaining the appropriate temperature is crucial to ensure the integrity and stability of stored medications and vaccines. Fiberglass mat tissue can help create a temperature-controlled environment by reducing heat transfer between different areas and protecting the stored products from external temperature fluctuations. Additionally, fiberglass mat tissue is lightweight, easy to install, and resistant to moisture, making it suitable for pharmaceutical storage areas where cleanliness and hygiene are essential. It can be easily placed between walls, ceilings, and floors to provide a barrier against heat flow, thus maintaining the desired temperature inside the storage area. Moreover, fiberglass mat tissue is a non-combustible material, which adds an extra layer of safety in pharmaceutical storage areas. It does not contribute to the spread of fire, ensuring the protection of valuable pharmaceutical products and reducing the risk of fire-related accidents. Overall, fiberglass mat tissue is an effective choice for insulation in pharmaceutical storage areas, providing thermal regulation, moisture resistance, cleanliness, and fire safety. It helps maintain the required temperature and ensures the integrity and stability of stored medications and vaccines.

- Q: How does fiberglass mat tissue compare to polyurethane insulation?

- Fiberglass mat tissue and polyurethane insulation have different characteristics and purposes. Fiberglass mat tissue is commonly used as a reinforcing material in composite structures, providing strength and stability. On the other hand, polyurethane insulation is specifically designed to reduce heat transfer and improve energy efficiency in buildings. Therefore, while fiberglass mat tissue enhances structural integrity, polyurethane insulation primarily focuses on thermal insulation properties.

- Q: What is the thermal resistance of fiberglass mat tissue?

- The thermal resistance of fiberglass mat tissue is determined by several factors, including the mat's thickness, fiber density, and the inclusion of additional materials or coatings. In general, fiberglass exhibits low thermal resistance, signifying its excellent heat conductivity. Nevertheless, when employed as insulation, the thickness and density of the fiberglass mat can elevate its thermal resistance, enhancing its ability to reduce heat transfer. It is crucial to acknowledge that precise thermal resistance values may differ based on the product and application, hence it is advisable to consult the manufacturer's specifications for precise information.

- Q: Can fiberglass mat tissue be used for making lightweight flooring?

- Making lightweight flooring is possible with the use of fiberglass mat tissue. This material is commonly found in the construction and manufacturing industries due to its strength, durability, and lightweight properties. It is created by bonding fine fiberglass strands together with a binder, resulting in a thin, flexible, and lightweight material. Using fiberglass mat tissue for flooring applications offers various advantages. Firstly, its lightweight nature makes it easy to handle and install, reducing the overall weight of the flooring system. This is particularly beneficial in situations where weight is a concern, such as in aircraft or mobile homes. Additionally, fiberglass mat tissue has an excellent strength-to-weight ratio, making it perfect for creating lightweight yet strong flooring. It reinforces and improves the structural integrity of the flooring, making it more resistant to cracking, warping, and other types of damage. Moreover, fiberglass mat tissue is resistant to moisture, chemicals, and fire, making it suitable for areas where these factors are present, such as bathrooms, kitchens, or industrial settings. It also provides good insulation properties, which helps maintain a comfortable indoor environment and reduces energy consumption. In conclusion, fiberglass mat tissue is an excellent choice for creating lightweight flooring due to its strength, durability, moisture resistance, and insulation properties. However, it is important to consider additional factors, such as the specific requirements of the flooring application, load-bearing capacity, and necessary certifications or standards before finalizing the use of fiberglass mat tissue in a flooring project.

- Q: Is fiberglass mat tissue water-resistant?

- Yes, fiberglass mat tissue is water-resistant. Fiberglass is a material composed of fine fibers of glass, which are woven together to form a mat. This mat is then coated with a water-resistant material, such as a resin or gel coat, to enhance its water resistance. The water-resistant coating prevents water from seeping into the fiberglass mat, making it suitable for various applications where exposure to water or moisture is expected, such as in boat hulls, shower stalls, and outdoor furniture. However, it is important to note that while fiberglass mat tissue is water-resistant, it is not completely waterproof. It may still absorb small amounts of water over time if not properly maintained or if exposed to prolonged and excessive moisture.

Send your message to us

Fiberglass Mat Tissue Glasswool Blanket Fire Protection Glass Wool Insulation

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords