Fiberglass Mat Tissue Glass Wool Blanket Waterproof Thermal Insulation

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of Glass Wool Blanket:

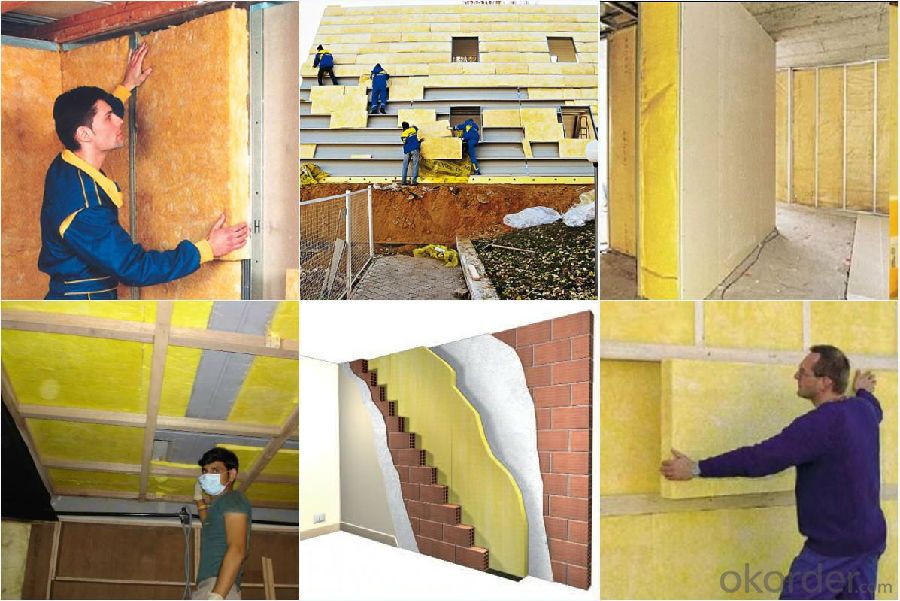

It is widely used for heat insulation and sound absorption in industrial workshops, Prefab houses, Portable cabins, warehouses, public facilities, exhibition centers, shopping malls, and a variety of indoor playgrounds, sports stadiums and etc..

Glass wool, which belongs to glass fiber , is a kind of man-made inorganic fiber. It is made from fibrosis glass melt in wool shape, which belongs to inorganic fiber and fiber in its chemical ingredient. Its merit is better in shape, low density and volume, low in thermal conduction, better heat preservation and thermal insulation, fine sound absorption, corrosion-resistant and stable chemical property. Glass wool blanket, glass wool board, glass wool pipe, which made from glass wool, largely use in construction, chemical, electronic, electricity, metallurgy, energy industry and community with good performance in heat preservation, heat insulation, sound absorption.

2.Main features of Glass Wool Blanket:

1) Heat insulation and heat preservation, sound adsorption and noise reduction

2) Low slag indusion content, thin and long inner fiber

3) Thermal stability, stable and high efficiency for a long time

4) High temperature heat-stability, durability, high temperature shrinkage resistance

5) Damp proof property, with the hydrophobicity are not less than 98%

6) Excellent fire proof performance, European standard non-flammable class A material

7) Non-poison, not contain rock wool and doesn't grow the mould etc.

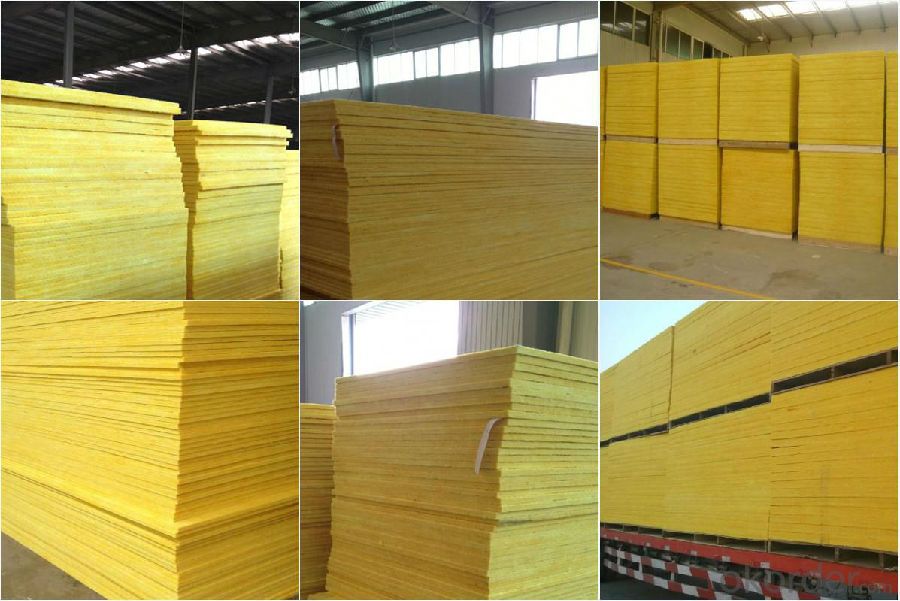

3.Glass Wool Blanket Images:

4. Glass Wool Insulation Blanket Technical Parameters:

Property | High/low temperature resistance, oil and fuel resistance, weathering resistance, O zone resistance etc. |

Shape | According to your requirement. |

Color | Any color is available ,according to your requirements. |

Material | NBR, CR, SBR, EPDM, IIR, NR, EP, Silicone, VITON etc. |

Hardness | 30-90ShoreA |

Delivery | In 10 days |

Packing | Plastic bag & carton box or according to your requirements. |

Application | Electronic field, industrial machine & equipment, house-hold appliance, telecommunication, automobile, medical equipment industry etc. |

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of Glass Wool Blanket is one of the large scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system every link from raw material to final product we have strict quality test; We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: How is fiberglass mat tissue used in the manufacturing of wind turbine blades?

- Fiberglass mat tissue is used in the manufacturing of wind turbine blades as a reinforcement material. It is typically sandwiched between layers of resin to provide strength, stiffness, and durability to the blades. The mat tissue helps to distribute and absorb the loads and stresses experienced by the blades during operation, making them more resistant to fatigue and structural failure.

- Q: What are the factors that affect the diameter of electrospun nanofibers?

- Application of drug controlled release, tissue engineering, the application of biomimetic materials and artificial organs, sensor film principle: electrospinning is a polymer solution (or melt) forming process of fiber in high voltage field, its core is to take charge of the polymer solution or melt flow and deformation in electrostatic field, and then by solvent evaporation or melt cooling and solid...

- Q: How does the density of fiberglass mat tissue affect its performance?

- The density of fiberglass mat tissue significantly affects its performance. Fiberglass mat tissue is typically used in various applications, such as insulation, construction materials, and composite materials. The density of the fiberglass mat tissue determines its strength, durability, flexibility, and thermal insulation properties. A higher density fiberglass mat tissue generally offers better strength and durability. This is because a higher density implies more fiberglass strands are packed closely together, resulting in a denser and stronger material. It can withstand higher loads and impacts, making it suitable for applications requiring structural integrity, such as in construction or automotive industries. Moreover, the density of fiberglass mat tissue also influences its flexibility. A lower density fiberglass mat tissue tends to be more pliable and easier to shape. It can be molded into intricate shapes and contours, making it suitable for applications where flexibility is essential, such as in boat manufacturing or automotive body parts. The density also affects the thermal insulation properties of fiberglass mat tissue. Higher density fiberglass mat tissue offers better insulation against heat transfer. It effectively prevents the transfer of heat through conduction, making it ideal for insulation purposes, such as in buildings or piping systems. However, it is important to note that the density of fiberglass mat tissue should be chosen based on the specific requirements of the application. While higher density may provide better strength and durability, it also increases the weight and cost of the material. Therefore, a balance needs to be struck between the desired performance characteristics and the practicality of the specific application.

- Q: How does the density of fiberglass mat tissue impact its performance?

- The density of fiberglass mat tissue significantly affects its performance. Fiberglass mat tissue is a nonwoven material composed of randomly dispersed glass fibers held together by a binder. The density of the tissue refers to the amount of fibers present in a given volume of the material. A higher density of fiberglass mat tissue generally results in improved mechanical properties and performance. The increased density means that there are more glass fibers per unit volume, leading to enhanced strength, stiffness, and durability. This makes the material more resistant to tearing, puncturing, and abrasion, which is particularly important in applications where the tissue is exposed to harsh conditions or heavy loads. Moreover, a higher-density fiberglass mat tissue offers better thermal insulation properties. The increased fiber content allows for better heat resistance, making it suitable for applications that require thermal protection, such as insulation boards or fireproofing materials. On the other hand, a lower density of fiberglass mat tissue may provide advantages in certain applications. Lower-density tissues are generally more flexible and have better conformability, allowing them to easily adapt to irregular surfaces or complex shapes. This makes them suitable for applications where flexibility or conformability is a primary requirement, such as in automotive or aerospace industries. Overall, the density of fiberglass mat tissue plays a crucial role in determining its performance characteristics. Whether a higher or lower density is preferred depends on the specific application requirements, considering factors such as strength, stiffness, durability, thermal insulation, flexibility, and conformability.

- Q: Can fiberglass mat tissue be used for insulating windows?

- No, fiberglass mat tissue is not suitable for insulating windows. It is primarily used for reinforcing and strengthening surfaces, such as in the construction industry, and is not designed to provide thermal insulation.

- Q: Can fiberglass mat tissue be used for repairing fiberglass boats?

- Yes, fiberglass mat tissue can be used for repairing fiberglass boats. It is commonly used in boat repairs to reinforce weak or damaged areas and provide strength and durability to the repaired sections.

- Q: Can fiberglass mat tissue be used for automotive repairs?

- Yes, fiberglass mat tissue can be used for automotive repairs. It is commonly used for reinforcing and repairing various parts of a vehicle, such as body panels, bumpers, and interior components. The fiberglass mat tissue provides strength, durability, and flexibility, making it an ideal material for automotive repairs.

- Q: Does anyone know the hardness value of the heat conductive gasket? Does it contain the hardness of the carrier (glass fiber)?

- The purpose of glass fiber is to make the product more convenient for processing, containing a layer of glass fiber cloth, then the operation process is not easy to damage thermal conductive gasket

- Q: Is fiberglass mat tissue suitable for sound absorption?

- Yes, fiberglass mat tissue is suitable for sound absorption. Fiberglass has excellent acoustic properties, making it an effective material for reducing noise levels and improving sound quality in various applications. The fibrous structure of the mat tissue provides a high surface area to absorb sound waves, converting them into heat energy. This makes it an ideal material for soundproofing walls, ceilings, and floors in buildings, as well as for use in automotive, industrial, and marine applications. Additionally, fiberglass mat tissue is lightweight, easy to install, and has good durability and fire resistance, further enhancing its suitability for sound absorption purposes.

- Q: How does the fiber content of fiberglass mat tissue affect its strength?

- The fiber content of fiberglass mat tissue directly affects its strength. The higher the fiber content, the stronger the fiberglass mat tissue will be. This is because the fibers provide the structural integrity and reinforcement to the material. When the fiber content is increased, it results in a higher concentration of fibers, which in turn increases the overall strength of the tissue. Fiberglass mat tissue is composed of glass fibers that are randomly oriented and bound together with a resin binder. These fibers are responsible for carrying the load and providing resistance to any external forces or stresses applied to the material. As a result, the more fibers present in the tissue, the greater the load-carrying capacity and strength of the material. Additionally, a higher fiber content enhances the stiffness of the fiberglass mat tissue. Stiffness refers to the ability of a material to resist deformation or bending under applied loads. With a greater amount of fibers, the tissue becomes stiffer, making it less prone to bending or flexing. This increased stiffness contributes to the overall strength of the material. It is important to note that while a higher fiber content improves the strength of fiberglass mat tissue, there is an optimal range where the benefits of additional fibers are maximized. Beyond this range, the increased fiber content may not result in a significant improvement in strength, and it may have diminishing returns. Therefore, it is crucial to find the right balance between fiber content and strength for specific applications. In conclusion, the fiber content of fiberglass mat tissue directly impacts its strength. Increasing the fiber content leads to a higher concentration of fibers, which enhances the material's load-carrying capacity and stiffness. Finding the optimal fiber content is essential to maximize the strength of the tissue for specific applications.

Send your message to us

Fiberglass Mat Tissue Glass Wool Blanket Waterproof Thermal Insulation

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords