Fiberglass Mat Tissue - Glass Fiber Chop Strand Mat Rolls, Fiberglass Mat

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1.5

- Supply Capability:

- 100 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Glass Fiber Chopped Strand Mat Rolls, Fiberglass Mat

Introduction:

Fiberglass chopped strand mat is a non-woven E-or C-glassfiber mat, product manufactured by spreading continuous filament roving of 50mm in length randomly and uniformly in combination with polyester binder in powder form (or other binder in emulsion from). This product is characterized by good combination of resin, easy operation, good wet strength retention, good laminate transparency and low cost. It is suitable for the applications of hand lay-up FRP moldings, such as various sheets and panels, boat hulls, bath tubs, cooling towers, corrosion resistant, vehicles etc.

Function:

Fiberglass chopped strand mat is chopped using the "E" chopped glass and emulsion adhesive bond. It is suitable for hand lay and can enhance the unsaturaed ployester resins.

Product Features:

Consistent thickness and stiffness;

Rapid impregnating and good compatibility with resin;

Superior wet through with less air trap;

Good mechanical properties and high strength of parts.

Superior acid corrosion resistance

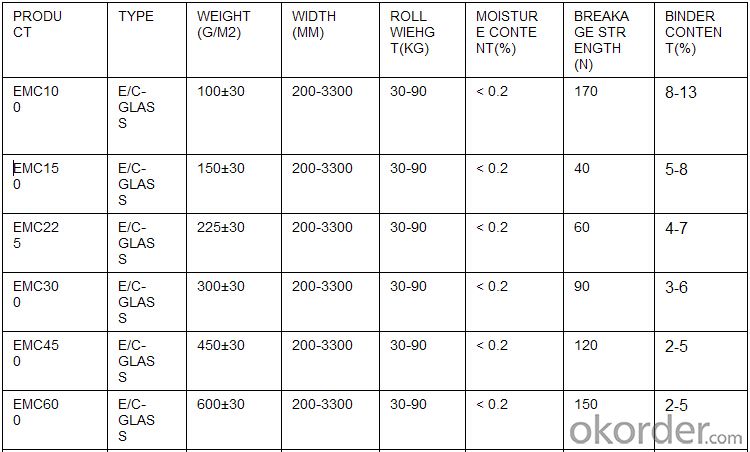

Technical Data:

FAQ:

Is sample available ?

Yes, we provide the free samples, but customers themselves need pay the shipping fee

What's your MOQ?

Our MOQ is one 1*20' full container loading

How do you pack the fiberglass

(1) First, the mat is in roll packed in White PE fIlm.

(2) Then the rolls packed in the carton

- Q: Can fiberglass mat tissue be used for windbreak panels?

- Windbreak panels can utilize fiberglass mat tissue, which functions as a lightweight and flexible material. This material is commonly utilized in insulation, reinforcement, and structural support applications. It is recognized for its durability, high strength-to-weight ratio, and ability to withstand various weather and environmental conditions. By incorporating fiberglass mat tissue into windbreak panels, additional reinforcement and stability are provided. This reinforcement allows the panels to endure strong winds without experiencing damage or breakage, rendering fiberglass mat tissue an effective choice for windbreak panels. Furthermore, fiberglass mat tissue possesses exceptional thermal and acoustic insulation properties. This feature contributes to the reduction of noise and regulation of temperature within windbreak panels, thus creating a more comfortable and protected environment. Additionally, this material is fire-resistant, ensuring the safety of windbreak panels. In summary, considering its strength, durability, insulation properties, and resistance to environmental conditions, fiberglass mat tissue proves to be a suitable and dependable material for windbreak panels.

- Q: What is the thickness range of fiberglass mat tissue?

- The thickness range of fiberglass mat tissue typically varies between 0.2mm to 3mm.

- Q: Is fiberglass mat tissue resistant to mold growth?

- Indeed, mold growth is effectively resisted by fiberglass mat tissue. The composition of fiberglass involves the interlacing of tightly woven glass fibers, yielding a substance highly impervious to moisture and mold. Moreover, fiberglass possesses a non-porous nature, signifying its inability to absorb water, thereby further deterring the proliferation of mold. Consequently, fiberglass mat tissue emerges as an optimal selection for circumstances necessitating mold resistance, such as insulation, wallboards, and various construction materials.

- Q: Does fiberglass mat tissue provide good acoustical performance?

- Fiberglass mat tissue does provide good acoustical performance. Due to its composition, which includes fine glass fibers, this material is effective in absorbing sound waves and reducing echo and reverberation in a space. Fiberglass mat tissue has excellent sound absorption properties, making it suitable for applications in various industries such as construction, automotive, and aerospace. Its ability to dampen sound and improve acoustics makes it a popular choice for soundproofing walls, ceilings, and floors in buildings. Additionally, fiberglass mat tissue is lightweight and easy to install, further enhancing its appeal for acoustical applications.

- Q: How long does fiberglass mat tissue typically last?

- The duration of fiberglass mat tissue's lifespan is subject to fluctuation due to a variety of factors, including material quality, exposure to environmental conditions, and maintenance level. Typically, fiberglass mat tissue has a lifespan of 20 to 30 years. Nevertheless, by implementing appropriate installation techniques and consistent maintenance practices, it has the potential to endure beyond this time frame. It is crucial to emphasize that routine inspections and maintenance aid in the detection of any indications of deterioration or harm, permitting prompt repairs or replacements to guarantee its longevity.

- Q: How is fiberglass mat tissue used in the production of printed circuit boards?

- Fiberglass mat tissue is commonly used in the production of printed circuit boards (PCBs) as a reinforcement material. PCBs are typically made of layers of copper, insulating materials, and fiberglass. The fiberglass mat tissue serves as a structural support and helps provide mechanical strength to the PCB. During the manufacturing process, the fiberglass mat tissue is impregnated with a resin, usually epoxy, to form a laminate material. This laminate is then layered with copper foils, which act as conductive pathways for the electrical signals on the PCB. The fiberglass mat tissue plays a crucial role in the PCB's performance and reliability. It provides a solid foundation for the copper layers, preventing them from delaminating or warping due to mechanical stress or temperature changes. It also helps to maintain the dimensional stability of the PCB, ensuring that it remains flat and rigid. Furthermore, the fiberglass mat tissue enhances the PCB's resistance to heat and moisture. The epoxy resin used in the laminate offers excellent insulation properties, protecting the copper conductors from short circuits or electrical leakage. Additionally, the fiberglass mat tissue acts as a barrier against moisture absorption, preventing the PCB from becoming damaged or malfunctioning. In summary, fiberglass mat tissue is an essential component in the production of printed circuit boards. It provides structural support, enhances mechanical strength, ensures dimensional stability, and improves resistance to heat and moisture. Ultimately, the use of fiberglass mat tissue contributes to the overall reliability and performance of PCBs in various electronic devices.

- Q: Can fiberglass mat tissue be used for making insulation jackets?

- Yes, fiberglass mat tissue can be used for making insulation jackets. Fiberglass mat tissue is a versatile material that is commonly used in various insulation applications due to its excellent thermal insulation properties. It is lightweight, flexible, and provides effective insulation against heat transfer. When used in insulation jackets, fiberglass mat tissue can help to retain heat and prevent heat loss, making it an ideal choice for applications where thermal insulation is required. Additionally, fiberglass mat tissue is also fire-resistant, which further enhances its suitability for insulation jackets.

- Q: Can fiberglass mat tissue be used for insulating refrigeration units?

- Yes, fiberglass mat tissue can be used for insulating refrigeration units.

- Q: Can fiberglass mat tissue be used for insulation in power plants?

- Indeed, insulation in power plants can make use of fiberglass mat tissue. Renowned for its remarkable thermal insulation characteristics, this lightweight and pliable material serves as an effective thermal barrier in a multitude of applications, including power plants. By insulating equipment and pipelines, fiberglass mat tissue curbs heat dissipation, thereby bolstering energy efficiency and thwarting heat loss. Furthermore, given its non-combustible nature, fiberglass mat tissue emerges as an ideal option for insulation in environments where fire safety reigns supreme.

- Q: Is fiberglass mat tissue suitable for automotive interiors?

- Yes, fiberglass mat tissue can be suitable for automotive interiors. Fiberglass mat tissue is a versatile material that is commonly used in various industries, including automotive manufacturing. It offers several benefits that make it suitable for automotive interiors. Firstly, fiberglass mat tissue provides excellent insulation properties. It helps in reducing noise, vibration, and harshness (NVH) levels inside the vehicle cabin. This can significantly enhance the overall comfort and driving experience for passengers. Secondly, fiberglass mat tissue is lightweight and flexible, making it easy to install in different areas of the car interior. It can be molded and shaped to fit various parts, such as door panels, headliners, trunk liners, and floor carpets. Its flexibility also allows for easy integration with other components, such as sound-deadening materials, to further improve insulation and reduce vibrations. Additionally, fiberglass mat tissue is resistant to heat, moisture, and chemicals, which are often present in automotive environments. This makes it a durable and long-lasting material that can withstand the unique conditions inside a vehicle. It is also resistant to mold and mildew growth, ensuring a clean and hygienic interior. Furthermore, fiberglass mat tissue can be easily coated or laminated with other materials to enhance its aesthetic appeal. It can be finished with various fabrics, vinyl, or leather to match the desired interior design and provide a luxurious feel. In summary, fiberglass mat tissue is a suitable material for automotive interiors due to its insulation properties, lightweight and flexible nature, durability, resistance to heat and moisture, and potential for aesthetic enhancements. Its usage can contribute to creating a comfortable, quiet, and visually appealing cabin space for vehicle occupants.

Send your message to us

Fiberglass Mat Tissue - Glass Fiber Chop Strand Mat Rolls, Fiberglass Mat

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1.5

- Supply Capability:

- 100 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords