Fiberglass Mat Tissue - E-Glass Stitched Chopped Mat (450g/m2~900g/m2)

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20000 kg

- Supply Capability:

- 200000kg Per Month kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Brief Introductions

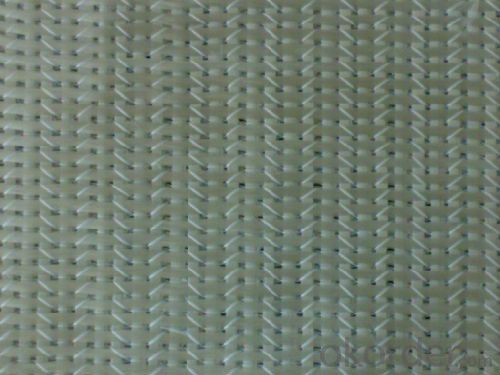

E-Glass Stitched Chopped Mat (450g/m2~900g/m2) is made by chopping continuous strands into chopped strands and stitching them together. The product has a maximum width of 110 inches. This product can be used in manufacturing boat manufacturing and tubes.

2.Product Features

Fast breakdown in styrene

Good wet-through and fast wet-out in resins, rapid air lease

Superior acid corrosion resistance

3.Product Specifications

Item | Over Density | Moisture Content | Chop Density | Polyester Yarn | Width |

(g/m2) | (%) | (g/m2) | (g/m2) | (mm) | |

EMK300 | 309.5 | ≤0.15 | 300 | 9.5 | 50-3300 |

EMK380 | 399 | 380 | 19 | ||

EMK450 | 459.5 | 450 | 9.5 | ||

EMK450 | 469 | 450 | 19 | ||

EMC0020 | 620.9 | 601.9 | 19 | ||

EMC0030 | 909.5 | 900 | 9.5 |

Special specification can be produce according to customer requirements.

4.FAQ

Packaging:

E-Glass Stitched Chopped Strand Mat is wound onto a paper tube which has an inside diameter of 76mm and the mat roll has a diameter of 275mm. The mat roll is wrapped up with plastic film,and then packed in a cardboard box or wrapped up with kraft paper. The rolls can be horizontally placed. For transportation, the rolls can be loaded into a cantainer directly or on pallets.

Storage:

Unless otherwise specified, E-Glass Stitched Chopped Strand Mat should be stored in a dry, cool and rain-proof area. It is recommended that the room temperature and humidity should be always maintained at 15℃~35℃ and 35%~65% respectively.

- Q: How does the roll diameter of fiberglass mat tissue affect its handling?

- The roll diameter of fiberglass mat tissue affects its handling by influencing its weight, ease of maneuverability, and the amount of material that can be handled at once. A larger roll diameter may be heavier and more challenging to handle, requiring more effort and potentially causing strain. Additionally, a larger roll diameter may limit maneuverability, making it harder to transport or position the material. Conversely, a smaller roll diameter is typically lighter and easier to handle, allowing for more flexibility in moving and manipulating the fiberglass mat tissue.

- Q: What is the moisture resistance rating of fiberglass mat tissue?

- The moisture resistance rating of fiberglass mat tissue is typically high, as it is designed to withstand exposure to moisture and is commonly used in applications where moisture resistance is important, such as in the construction industry for waterproofing and insulation purposes.

- Q: Can fiberglass mat tissue be used for insulation boards?

- Insulation boards can indeed utilize fiberglass mat tissue as a viable option. This lightweight and flexible material consists of delicate glass fibers melded together with a resin. Its outstanding thermal insulation qualities make it an optimal selection for insulation boards. The mat tissue is effortlessly customizable, capable of conforming to various shapes and sizes, thereby facilitating insulation of walls, roofs, floors, and other areas within a structure. Notably, it possesses resistance against moisture, mold, and mildew, ensuring enduring insulation performance. Moreover, fiberglass mat tissue exhibits fire-resistant properties, further bolstering its suitability for insulation applications. In summary, fiberglass mat tissue proves to be an adaptable and efficient material for insulation boards.

- Q: Can fiberglass mat tissue be used for insulation in shopping malls?

- Indeed, insulation in shopping malls can incorporate the utilization of fiberglass mat tissue. This material is widely employed and proven to be efficient for thermal insulation owing to its low thermal conductivity and exceptional resistance to heat transfer. Moreover, fiberglass mat tissue possesses the advantage of being non-combustible, rendering it a secure choice for commercial structures such as shopping malls. Furthermore, its lightweight nature facilitates effortless installation, and its superb sound absorption properties contribute to establishing a pleasant and serene ambiance in the mall. All in all, fiberglass mat tissue emerges as an appropriate selection for insulation in shopping malls, ensuring energy efficiency and enhanced indoor comfort.

- Q: How does fiberglass mat tissue compare to polyurethane insulation?

- Fiberglass mat tissue and polyurethane insulation are two commonly used materials in the construction industry, but they have distinct differences in terms of composition, performance, and applications. Fiberglass mat tissue is made from glass fibers that are woven into a mat-like structure. It is primarily used as a reinforcement material in various applications such as roofing, wall insulation, and fiberglass composites. The main advantage of fiberglass mat tissue is its high tensile strength, which provides excellent structural support and durability. It is also resistant to fire and chemicals, making it a suitable choice for applications where safety is a concern. On the other hand, polyurethane insulation is a foam material that is known for its excellent thermal insulation properties. It is commonly used in buildings to reduce heat transfer and improve energy efficiency. Polyurethane insulation has a high R-value, which indicates its ability to resist heat flow. This makes it an ideal choice for insulation purposes, especially in areas with extreme temperature conditions. Additionally, polyurethane insulation is lightweight, easy to install, and has good moisture resistance. When comparing fiberglass mat tissue to polyurethane insulation, it is important to consider the specific needs and requirements of the project. Fiberglass mat tissue is more suitable for applications that require structural reinforcement, such as roofing and composite materials. It provides excellent strength and durability, making it a preferred choice for such applications. On the other hand, polyurethane insulation is more effective in terms of thermal insulation. It offers superior heat resistance and has a higher R-value compared to fiberglass mat tissue. Therefore, if the primary goal is to improve energy efficiency and reduce heat transfer, polyurethane insulation would be the better choice. Overall, fiberglass mat tissue and polyurethane insulation have their own strengths and weaknesses. The decision on which material to use should be based on the specific requirements of the project, such as structural support or thermal insulation needs. Consulting with a professional and considering factors such as budget, environmental impact, and local building codes can help in making an informed decision.

- Q: How does the porosity of fiberglass mat tissue affect its performance?

- The porosity of fiberglass mat tissue plays a significant role in determining its performance. Porosity refers to the density of tiny pores or holes in the material, which affects the material's ability to absorb and hold fluids, as well as its strength and durability. Firstly, the porosity of fiberglass mat tissue influences its absorption capability. A higher porosity allows the tissue to absorb more fluids, such as resins or binders, during the manufacturing process. This absorption is crucial as it ensures better adhesion between the fiberglass mat and the bonding material, resulting in a stronger and more durable end product. Secondly, the porosity of the fiberglass mat tissue affects its strength and stiffness. Lower porosity generally indicates higher density and a more tightly packed structure, resulting in increased strength and stiffness. This is beneficial in applications where the material needs to withstand high mechanical stresses or act as a structural component. Additionally, the porosity of the fiberglass mat tissue impacts its thermal and acoustic insulation properties. Higher porosity typically leads to better thermal and acoustic insulation due to the increased number of air pockets within the material. These air pockets act as barriers, reducing heat transfer and sound transmission, making the material suitable for applications requiring thermal or acoustic insulation. Furthermore, the porosity of fiberglass mat tissue can influence its filtration capabilities. If the material has a high porosity, it can trap and hold particles more effectively, making it suitable for use in filtration systems. Conversely, a low porosity may allow for better flow rates, making it more suitable for applications where fluid permeability is important, such as drainage applications. In summary, the porosity of fiberglass mat tissue affects its performance in various ways. It determines its absorption capability, strength, stiffness, thermal and acoustic insulation properties, filtration capabilities, and fluid permeability. Therefore, understanding and controlling the porosity of fiberglass mat tissue is essential to ensure optimal performance in a wide range of applications.

- Q: Is fiberglass mat tissue suitable for oil and gas applications?

- Yes, fiberglass mat tissue is suitable for oil and gas applications. It is corrosion resistant, has high mechanical strength, and can withstand high temperatures, making it an ideal material for various oil and gas industry requirements such as insulation, reinforcement, and filtration. Additionally, fiberglass mat tissue has excellent chemical resistance, ensuring its durability and reliability in harsh environments commonly found in the oil and gas sector.

- Q: How does fiberglass mat tissue perform in terms of thermal resistance?

- Fiberglass mat tissue performs exceptionally well in terms of thermal resistance. Due to the inherent properties of fiberglass, such as low thermal conductivity and high melting point, the mat tissue effectively acts as a barrier against heat transfer. It efficiently blocks the conduction of heat, limiting thermal energy from passing through the material. This makes fiberglass mat tissue an excellent choice for insulation applications where thermal resistance is crucial, such as in buildings, industrial equipment, and automotive components. Additionally, fiberglass mat tissue is known for its fire-resistant properties, further enhancing its ability to withstand high temperatures and provide excellent thermal insulation.

- Q: Can fiberglass mat tissue be used in marine applications?

- Yes, fiberglass mat tissue can be used in marine applications. Fiberglass mat tissue is a lightweight and flexible material that is commonly used in boat building and repair. It provides excellent strength and durability, making it suitable for marine environments where the material is exposed to water, salt, and other harsh conditions. Fiberglass mat tissue is often used as a reinforcement layer in the construction of boat hulls, decks, and other structural components. It helps to add strength and stiffness to the composite materials used in marine applications, enhancing their overall performance and longevity. Additionally, fiberglass mat tissue is resistant to corrosion and has good water resistance properties, making it well-suited for marine applications.

- Q: Can fiberglass mat tissue be used for insulation in cleanrooms?

- Fiberglass mat tissue can indeed be used for insulation in cleanrooms. It offers several advantages that make it a suitable choice for such applications. Firstly, fiberglass mat tissue has excellent thermal insulation properties, which helps to maintain the desired temperature and prevent heat transfer in cleanrooms. This is crucial in environments where temperature control is essential for processes or equipment. Additionally, fiberglass mat tissue has good acoustic insulation capabilities, which can help in reducing noise levels within cleanrooms. This is particularly important in cleanrooms where sensitive equipment or experiments are conducted, as minimizing noise disturbances can ensure accurate and reliable results. Furthermore, fiberglass mat tissue is non-combustible, meaning it does not catch fire easily. This adds an extra layer of safety in cleanrooms where flammable materials or volatile substances may be present. The non-combustible nature of fiberglass mat tissue also contributes to its overall durability and longevity. Lastly, fiberglass mat tissue is resistant to moisture, making it suitable for cleanrooms where humidity control is crucial. It does not absorb moisture, preventing the growth of mold or mildew, which can be detrimental to cleanroom environments. Overall, fiberglass mat tissue is a viable option for insulation in cleanrooms due to its thermal and acoustic insulation properties, non-combustible nature, and resistance to moisture. Its use can contribute to maintaining the desired conditions within cleanrooms and ensuring the integrity of processes and equipment.

Send your message to us

Fiberglass Mat Tissue - E-Glass Stitched Chopped Mat (450g/m2~900g/m2)

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20000 kg

- Supply Capability:

- 200000kg Per Month kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords