Fiberglass Mat Tissue - e-glass Fiber Stitch Chopped Strand Mat 300gsm Width 50-2400mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 kg

- Supply Capability:

- 10000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

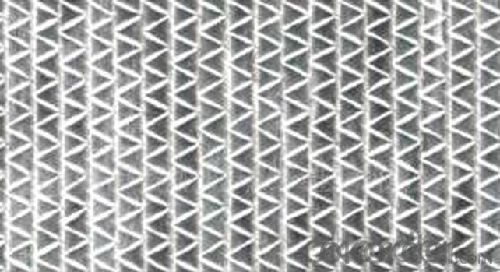

E-glass Fiber Stitch Chopped Strand Mat with Density 300gsm, Width 50-2400mm

Description

Fiberglass stitch chopped strand mat is the mat made of fiberglass roving which is at first be cut into certain length and evenly unfolded in all directions and then stitched with polyester yarn.

Main features:

◎ Uniform thickness, good wet tensile strength retention.

◎ Good mould-ability, good drapability and easy operation.

◎ Good wet out speed and high efficiency in production.

Images:

Specifications&Details

specifications | Fibre type | Areal weight | Width |

(g/㎡) | (mm) | ||

EMK 300 | E-Glass | 300 | 50-2400 |

EMK380 | E-Glass | 380 | 50-2400 |

EMK450 | E-Glass | 450 | 50-2400 |

CMK 300 | C-Glass | 300 | 50-2400 |

CMK380 | C-Glass | 380 | 50-2400 |

CMK450 | C-Glass | 450 | 50-2400 |

Packaging: Wrapped in PVC and placed within a cardboard carton. | |||

FAQ

Payment terms?

We can accept L/C, T/T etc.

Do you offer OEM service?

Yes, we can print customers’ logo on the packaging;

And the size and specification can be produced and design according to your demand.

- Q: Is fiberglass mat tissue resistant to oil and grease?

- Indeed, oil and grease do not affect fiberglass mat tissue due to its resistance. The structure of this tissue encompasses delicate glass fibers, tightly bound by a resin. This resin serves as a protective shield, prohibiting the penetration of oil and grease into the mat tissue, thus granting it resistance against these substances. Moreover, fiberglass possesses inherent non-reactive characteristics, amplifying its ability to withstand oil and grease. Consequently, fiberglass mat tissue proves to be an exemplary material for circumstances involving anticipated contact with oil and grease, such as industrial environments or automotive components.

- Q: Are there any specific certifications or standards that fiberglass mat tissue must meet?

- Yes, there are specific certifications and standards that fiberglass mat tissue must meet in order to ensure its quality and suitability for various applications. One of the most widely recognized standards for fiberglass mat tissue is the ASTM D 4601 standard, which establishes the minimum requirements for glass fiber mats used in roofing and waterproofing systems. This standard covers the physical properties of the mat such as weight, thickness, tensile strength, tear resistance, and water resistance. In addition to ASTM D 4601, there are other certifications and standards that fiberglass mat tissue can be tested against, depending on its intended use. For instance, fiberglass mat tissue used in the automotive industry may need to meet specific standards such as ISO 9001 or IATF 16949, which ensure quality management systems and product consistency. Moreover, fiberglass mat tissue used in construction or building materials may need to comply with standards set by regulatory bodies or organizations such as the International Code Council (ICC), the American National Standards Institute (ANSI), or the Underwriters Laboratories (UL). These standards typically focus on fire resistance, thermal insulation properties, and overall safety. Overall, the specific certifications and standards that fiberglass mat tissue must meet depend on its intended application and the industry in which it is used. These standards play a crucial role in ensuring the quality, performance, and safety of fiberglass mat tissue products.

- Q: How is fiberglass mat tissue used in the production of shower enclosures?

- Fiberglass mat tissue is used in the production of shower enclosures to reinforce the structure and provide added strength. It is typically applied as a layer between the gel coat and the fiberglass resin, creating a durable and rigid surface that can withstand daily use and potential impacts. The fiberglass mat tissue helps prevent cracking and warping, ensuring the shower enclosure maintains its shape and integrity over time.

- Q: What is the tear strength of fiberglass mat tissue?

- The tear strength of fiberglass mat tissue refers to the ability of the material to resist the propagation of tears or cracks when subjected to external forces. It is a crucial characteristic that determines the durability and performance of fiberglass mat tissue in various applications. The tear strength of fiberglass mat tissue is typically measured using standardized testing methods, such as the ASTM D1922 tear resistance test. This test involves subjecting a sample of the material to a controlled force, typically in the form of a tensile load, and measuring the force required to cause a tear or rupture. The tear strength of fiberglass mat tissue can vary depending on factors such as the manufacturing process, the quality of the raw materials used, and the specific application requirements. Generally, fiberglass mat tissues are designed to have high tear strength to withstand the stresses and strains encountered during installation and use. Fiberglass mat tissue is commonly used in industries such as construction, automotive, aerospace, and marine, where its high tear strength and other desirable properties make it an ideal choice. It is often utilized as a reinforcement material in composites, providing added strength and durability to the final product. In conclusion, the tear strength of fiberglass mat tissue is an important property that determines its resistance to tearing or cracking under applied forces. By ensuring a high tear strength, fiberglass mat tissue can withstand the demands of various applications and provide long-lasting performance.

- Q: Can fiberglass mat tissue be used for making swimming pool shells?

- Yes, fiberglass mat tissue can be used for making swimming pool shells. Fiberglass mat tissue is a strong and durable material that is commonly used in construction and manufacturing industries for its excellent properties. It is made by bonding fine glass fibers together with a resin binder, resulting in a flexible and lightweight material. When used for making swimming pool shells, fiberglass mat tissue provides a number of advantages. Firstly, it is highly resistant to water, making it an ideal choice for swimming pool applications. It is also resistant to chemicals commonly found in pool water, such as chlorine, ensuring the longevity of the pool shell. Additionally, fiberglass mat tissue is easy to work with and can be molded into any desired shape or size. This allows for the creation of custom-designed swimming pool shells, catering to specific requirements and preferences. The material's flexibility also enables it to withstand ground movement and temperature changes, ensuring the structural integrity of the pool shell. Furthermore, fiberglass mat tissue has a smooth surface finish, making it aesthetically pleasing and comfortable to touch. It can be easily painted or coated with gel coats to enhance its appearance and protect it from UV rays, preventing discoloration and deterioration over time. In conclusion, fiberglass mat tissue is an excellent choice for making swimming pool shells due to its water and chemical resistance, flexibility, durability, and aesthetic appeal.

- Q: Can fiberglass mat tissue be used for making electrical enclosures?

- No, fiberglass mat tissue is not suitable for making electrical enclosures. Electrical enclosures require materials that have good electrical insulation properties to prevent electrical shocks and short circuits. Fiberglass mat tissue is primarily used for reinforcement in composites and does not possess the necessary electrical insulation properties. Materials such as plastics, polymers, or metals with appropriate electrical insulation characteristics should be used for making electrical enclosures.

- Q: Can fiberglass mat tissue be used for making lightweight automotive parts?

- Yes, fiberglass mat tissue can be used for making lightweight automotive parts.

- Q: Can fiberglass mat tissue be used for repairing fiberglass tanks?

- Yes, fiberglass mat tissue can be used for repairing fiberglass tanks. It is commonly used as a reinforcement material to strengthen and repair damaged areas in fiberglass tanks due to its high tensile strength and compatibility with fiberglass resin.

- Q: Can fiberglass mat tissue be used for ballistic protection?

- Fiberglass mat tissue can be used for ballistic protection to some extent, but it may not offer the same level of protection as other materials specifically designed for this purpose. Fiberglass mat tissue is typically used in applications such as insulation, reinforcement, and fire resistance due to its high strength and heat resistance properties. However, when it comes to ballistic protection, there are more specialized materials available that are specifically engineered to withstand the impact of bullets or other projectiles. These materials often include aramid fibers (such as Kevlar) or ultra-high-molecular-weight polyethylene fibers (such as Dyneema) which are much more effective in providing superior ballistic protection. If ballistic protection is the primary concern, it is recommended to choose materials specifically designed for this purpose rather than relying solely on fiberglass mat tissue.

- Q: Is fiberglass mat tissue compatible with different types of resins?

- Yes, fiberglass mat tissue is compatible with different types of resins. It is commonly used in the construction industry as a reinforcement material for various resin systems, including polyester, epoxy, and vinyl ester resins. The compatibility of fiberglass mat tissue with different resins makes it versatile and suitable for a wide range of applications.

Send your message to us

Fiberglass Mat Tissue - e-glass Fiber Stitch Chopped Strand Mat 300gsm Width 50-2400mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 kg

- Supply Capability:

- 10000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords