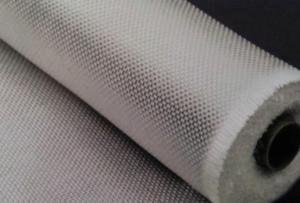

Fiberglass Mat Tissue E-Glass Fiberglass Woven Roving, 800g, 1040mm

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Brief Introduction

E-glass woven roving Fabric is bidirectional fabric made by 4.5 microns to 17 microns of E-Glass fiber,its high strength ,high modulus ,acid and alkali resistance , high temperature resistance and other properties. often used in protection ,heat insulation ,thermal insulation ,support field . After surface treatment ,it can be made into perfect composite materials . now it is widely used in hand lay up and robot processes to manufacture boats ,vessels ,plane and automotive parts , furniture and sports facilities.

Specifications:

PRODUCT CODE | WOVEN WEIGHT (OZ/YD) | WOVEN WEIGHT (GSM) | STANDARD WIDTH (INCHES) | ROLL LENGTH (M) | THICKNESS (MM) | LOI % | Moisture Content (%) |

CT-PWR24 | 0.86 | 24 | 50 | 50M | 0.04 | ≤0.80 | ≤0.20 |

CT-PWR48 | 1.71 | 48 | 50 | 50M | 0.06 | ≤0.80 | ≤0.20 |

CT-PWR100 | 2.95 | 100 | 50 | 50M | 0.11 | ≤0.80 | ≤0.20 |

CT-PWR135 | 3.99 | 138 | 50 | 50M | 0.14 | ≤0.80 | ≤0.20 |

CT-PWR200 | 5.9 | 200 | 50 | 50M | 0.18 | ≤0.80 | ≤0.20 |

CT-PWR290 | 8.56 | 290 | 50 | 50M | 0.23 | ≤0.80 | ≤0.20 |

Main features:

1.warp and weft rovings aligned in a parallel,flat manner and uniform tension.

2.densely aligned fiber,providing high dimensional stablity and easy handing.

3.good moldability,fast and complete resin wet-out ,enabling high productivity

4.good transparency and high strength of the composite products

Remark:Woven rovings are available in the width range of 50-3000mm and the weight range of 200-1600g/m2

Packaging:

It’s wound into a paper tube( inside diameter about 90mm, outside diameter about 265mm).the mat roll is wrapped with plastic film,and then packed into cardboard box or wrapped with paper.the rolls can be stacked horizontally.the rolls can be palletized or loaded into container.

FAQ:

1.What is the delivery time ?

15days after receiving the deposit

2.Are you a trading company or factory.

We are factory,and we have more than 10 years of experience.

- Q: Are there any health risks associated with fiberglass mat tissue?

- Yes, there are some health risks associated with fiberglass mat tissue. Fiberglass contains tiny fibers that when inhaled can irritate the respiratory system and potentially cause lung damage. Prolonged or repeated exposure to fiberglass fibers can also lead to a condition called fiberglass dermatitis, which causes skin irritation and itching. Therefore, proper precautions such as wearing protective clothing and masks should be taken when handling fiberglass mat tissue to minimize the health risks.

- Q: Is fiberglass mat tissue suitable for insulation in wastewater treatment plants?

- Yes, fiberglass mat tissue is suitable for insulation in wastewater treatment plants. Wastewater treatment plants often require insulation to prevent heat loss, control temperature, and protect against corrosion. Fiberglass mat tissue is a commonly used material for insulation in these facilities due to its high thermal resistance, excellent chemical resistance, and durability. It can effectively insulate pipes, tanks, and other equipment in wastewater treatment plants, ensuring optimal performance and energy efficiency. Additionally, fiberglass mat tissue is lightweight, easy to install, and cost-effective, making it a practical choice for insulation in these harsh environments.

- Q: What are the different weights available for fiberglass mat tissue?

- Various industries, including construction, automotive, and marine, utilize fiberglass mat tissue extensively. This versatile material is available in different weights or thicknesses to meet various applications and specifications. The weight of fiberglass mat tissue is typically measured in grams per square meter (gsm) or ounces per square yard (oz/yd²). Typically, the available weights for fiberglass mat tissue range from approximately 30 gsm (1 oz/yd²) to 150 gsm (5 oz/yd²) or higher. The weight of the tissue directly affects its strength, rigidity, and durability. For applications that require a high degree of flexibility and conformability, lightweight fiberglass mat tissue weighing around 30-50 gsm (1-1.5 oz/yd²) is commonly used. These lighter weight tissues are often employed in the production of laminates, reinforcing materials, and lightweight composites. Medium weight fiberglass mat tissue, typically falling within the range of 70 gsm (2 oz/yd²) to 100 gsm (3 oz/yd²), strikes a balance between flexibility and strength. It finds frequent use in applications such as roofing, insulation, and wall panels, where structural integrity and thermal insulation properties are of utmost importance. For applications that demand exceptional strength and rigidity, heavyweight fiberglass mat tissue weighing between 120 gsm (4 oz/yd²) and 150 gsm (5 oz/yd²) or more is ideal. This type of tissue is commonly employed in demanding applications like boat hulls, automotive body parts, and industrial equipment, where durability and resistance to impact and stress are critical. It is important to recognize that the availability of different weights of fiberglass mat tissue may vary depending on the manufacturer and the specific requirements of the application. In certain cases, custom weights can be manufactured to meet unique project needs. In summary, fiberglass mat tissue is available in a range of weights to accommodate diverse applications. Selecting the appropriate weight is essential to ensuring optimal performance and long-term durability in various industries.

- Q: What is the thermal conductivity of fiberglass mat tissue?

- The thermal conductivity of fiberglass mat tissue is typically low, ranging from 0.03 to 0.06 W/m·K.

- Q: Can fiberglass mat tissue be used in high-temperature applications?

- No, fiberglass mat tissue cannot be used in high-temperature applications.

- Q: How is fiberglass mat tissue used in the production of shower enclosures?

- Fiberglass mat tissue is used in the production of shower enclosures to reinforce the structure and provide added strength. It is typically applied as a layer between the gel coat and the fiberglass resin, creating a durable and rigid surface that can withstand daily use and potential impacts. The fiberglass mat tissue helps prevent cracking and warping, ensuring the shower enclosure maintains its shape and integrity over time.

- Q: Can fiberglass mat tissue be used for bridge construction?

- Yes, fiberglass mat tissue can be used for bridge construction. Fiberglass mat tissue is a versatile material that offers several advantages. It is lightweight yet strong, making it suitable for use in bridge construction where weight considerations are important. Additionally, fiberglass mat tissue is highly durable and resistant to corrosion, which is crucial for the longevity and maintenance of bridges. It can also be easily molded into various shapes, allowing for flexibility in bridge design. Moreover, fiberglass mat tissue has good impact resistance and excellent fatigue performance, ensuring the bridge's ability to withstand heavy loads and constant traffic. Overall, fiberglass mat tissue is a reliable and cost-effective material for bridge construction.

- Q: Can fiberglass mat tissue be used for insulating exterior walls?

- Yes, fiberglass mat tissue can be used for insulating exterior walls. Fiberglass mat tissue is a type of insulation material that is commonly used for its excellent thermal and acoustic insulation properties. It is made of fine glass fibers that are bonded together with a binder, creating a flexible and lightweight material. When used for insulating exterior walls, fiberglass mat tissue is typically installed between the wall studs or in the wall cavities. It helps to reduce heat transfer by trapping air within its fibers, which acts as a barrier against heat loss or gain. This insulation material can significantly improve the energy efficiency of a building by reducing the need for heating or cooling, thereby reducing energy costs and carbon emissions. Fiberglass mat tissue is also resistant to moisture, mold, and mildew, making it suitable for exterior applications. It helps to create a more comfortable and healthier indoor environment by preventing the growth of harmful microorganisms and reducing condensation. Additionally, fiberglass mat tissue is fire-resistant, adding an extra layer of safety to the building. Overall, fiberglass mat tissue is a versatile and effective insulation material that can be used for insulating exterior walls. Its thermal, acoustic, moisture resistance, and fire-resistant properties make it an excellent choice for improving the energy efficiency and comfort of buildings.

- Q: What about high temperature fiberglass?

- There seems to be a glass fiber cloth, that the head feels the hard plastic feeling, glass cloth drill burr is hard or soft brush to feel it, the heat melts can be adsorbed on the food on it

- Q: Is fiberglass mat tissue resistant to corrosion?

- Indeed, corrosion is not a concern for fiberglass mat tissue as it is comprised of non-metallic elements like glass fibers, unlike metals which are susceptible to rust and corrosion. This quality renders fiberglass mat tissue highly suitable for various purposes that demand resistance against corrosion, such as reinforcing concrete structures within the construction sector or for boat building in the marine industry. Furthermore, fiberglass mat tissue exhibits resistance towards chemicals, moisture, UV rays, and extreme temperatures, thereby augmenting its strength and longevity.

Send your message to us

Fiberglass Mat Tissue E-Glass Fiberglass Woven Roving, 800g, 1040mm

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords